Yellow ooze and Wrong turn Hotend? 🙁

I've had my printer for almost a year and have had nothing but good things to say until it needed a nozzle change... I figured go big or go home so I decided it was a good idea to get the Olsson Rube nozzle on prusa3d and for a week or so it was great. Until now. When it was printing I noticed an awful smell coming from it and worrying it was the power supply I immediately cancelled the print, reset the printer and un plugged it. Come to find out theres this yellow ooze coming from the edges of the hotend and heater cartridge. I have seen horror stories like this before but I caught mine early, if you are unfamiliar I believe this can happen if the hotend is not butted up against the heatsync and the plastic makes it's way down the screw part or up and over the block but I dont think this is the case because I remember when tightening the hotend on, it was very snug. When looking at the old hotend (the one that came with the printer) I saw that the screw was backwards from a regular, right hand screw... However, the tool I had used to tighten the Olsson nozzle on with was for right hand screws and would *click* whenever you tightened it too far right. Before ruining something I thought I should ask the forum. If you need any other pictures, have a left hand version or if you have had a similar experience, it would be extremely appreciated. 🙂

Re: Yellow ooze and Wrong turn Hotend? 🙁

Hi Beth,

I can't see your pictures, so guessing.

you changed the nozzle, so, probably that's the root cause of your filament leak!

normally when reassembling the hot end, you will have a heatblock with heater and thermistor glued into place with old waste filament, and an old nozzle that you removed when the hot end was hot, and a heat break, which may, or may not be screwed together.

the temptation is to whack the new nozzle in, and get back to printing.

and this is probably what you did.

what you should have done, was remove the heatbreak from the heat block,

screw the new nozzle fully into the heat block, then unscrew it about 1/2 turn. than screw the heatbreak back into the heat block, until the end buts firmly against the end of the nozzle.

heat the hot end, then tighten the nozzle fully against the heat break...

what has probably happened is that your nozzle may have had a marginally shorter screw thread than the original, and when you screwed it in, the nozzle tightened against the heat block, not the heat break, leaving a tiny gap between the heatbreak and the nozzle, where the filament escaped.

so to correct the issue, remove the new nozzle, and heatbreak whilst the heatblock is hot.

clean the waste plastic off,

re assemble as suggested,

cross your fingers, toes, eyes and anything else capable of crossing, and try another print..., it is probable that your live Z will be out f adjustment, so best note your current live Z, adjust to 0. before starting live Z calibration, to prevent damage to your heat bed. and complete live z adjustment.

I suspect liveZ for an ohlsson ruby will be a little less than a standard nozzle, because I believe the nozzle tip to rear of the nozzle nut dimension is marginally longer on the ohlsson ruby, than the standard e3d nozzle.

but that's all guesswork based on visual estimation of the different shapes, as I have never owned a ruby nozzle

compare your ruby live Z against your old live Z, and it may help you estimate probable changes if you go back to a standard nozzle!

good luck,

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Yellow ooze and Wrong turn Hotend? 🙁

😯

Wow Joan, this procedure was new to me (admitting I am a newbe).

I upgraded to the Olsson Ruby a few weeks ago and so far it worked well, though the amount of printing has been limited.

But reading the texts from Beth and you I worry a little that I might have the same problem coming up / latently.

What strikes me is that AFAIK this procedure and the possible repercussions of not following it is not at all mentionend in the Prusa operation manual, How to change the nozze (though the manual author mentions alterative nozzles like the Olsson).

I suggest that this chapter is updated to include this procedure, preferabely with pictures like the other well made Howto´s.

I cross my fingers that things will just keep working 😎

Re: Yellow ooze and Wrong turn Hotend? 🙁

Crap. I seem to have exactly the same problem.

I really wished I know about this before switching to the Olsson Ruby.

Beth, how did it go with your cleanup?

Mine is quite messy...

Re: Yellow ooze and Wrong turn Hotend? 🙁

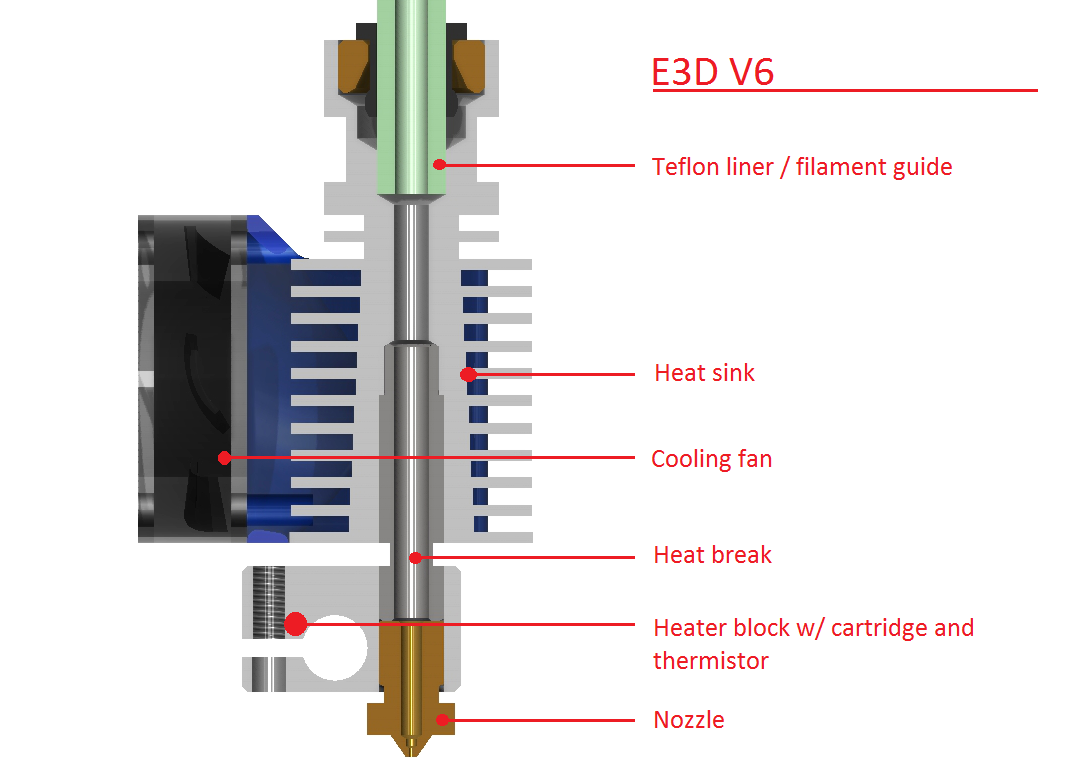

The Hot End ... the nozzle must tighten against the heat break, not the heater block.

Your photos show that the nozzle is tightened against the block, as Joan suggested. You will need to remove the hot end to ensure the heat break is threaded into the heat block far enough the nozzle makes contact to it before the HEX portion hits the block. The notch on the heat break should be visible above the heater block. But with your nozzle you may need to turn it farther in to compensate for the shorter nozzle -- you may want to measure your ruby to make sure it is the correct length for the E3D hot end (drawing attached).

Re: Yellow ooze and Wrong turn Hotend? 🙁

Thank you for the prompt response and the detailed advice. Actually I cleaned it up before noticing your post, using Joan's simple instructions, and it worked! No doubt others will benefit from your post 🙂

I had to heat the heatbreak thread with a hot air gun to be able to clean it - using a textile rag.

I have test run the printer afterwards and it seems to work fine now, no signs of leaks 🙂

The threaded part of the Olson Ruby nozzle is 0.75 mm shorter than on the original nozzle.

Re: Yellow ooze and Wrong turn Hotend? 🙁

Hi Sodergren,

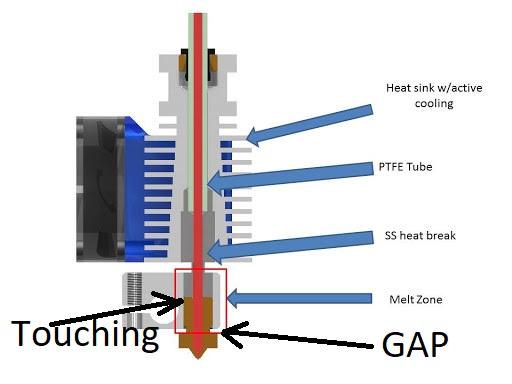

Tim's image of the e3D v6 doesn't fully reflect what is in the Prusa,

and I am sad to say, neither does the one that I am going to use...

in the image above, the PTFE goes all of the way into the top of the stainless steel heatbreak, the other picture shows it stopping short...

I have indicated:

where there should be a gap between the nozzle and the heat block, and

where the heat break and the nozzle should be in intimate contact. the end of the brass on your nozzle should be touching the end of the stainless steel heatbreak

You need to dissassemble the nozzle whilst the heatblock is hot (BE VERRY VERRY careful... the Ohlsson Ruby nozzle assembly is very weak between the hex nut and the screw thread... Twisting without heating, is almost guaranteed to break the thread off the hex part...

Good luck, Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Yellow ooze and Wrong turn Hotend? 🙁

Guess my last post was a bit late. 🙁

I posted it anyway, to show the revised diagram in the hopes that it helps others.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Yellow ooze and Wrong turn Hotend? 🙁

Thank you again, Joan.

I fixed it, thanks to your advice. 😎

I repeat that your info about this should be included in the Prusa handbook / howto:s - I was not the first to make the mistake and I will not be the last.

Maybe you have an open channel to the instruction manual department 😉 :ugeek:

Tomas

Re: Yellow ooze and Wrong turn Hotend? 🙁

And if we are nit-picking, both sketches show the hot end PTFE collet in the unlocked position, it should be UP, in the locked position.

Re: Yellow ooze and Wrong turn Hotend? 🙁

and with its lock clip in place 😀