RE: Under extrusion first layer

Nope, that's not under extrusion, your first layer z offset needs lowering more (closer to the bed) to give more squish to the filament.

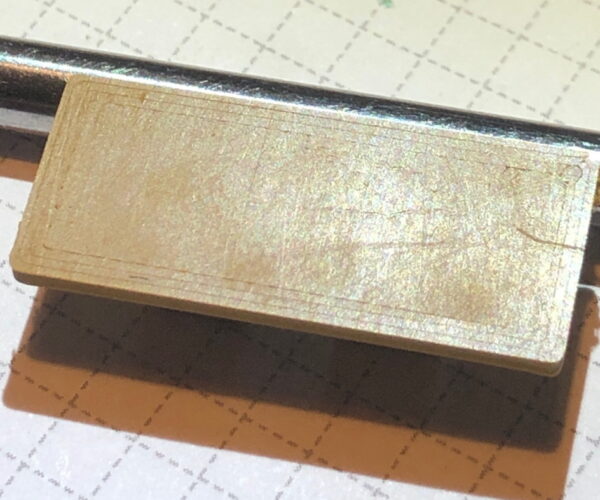

You are aiming for an unbroken first layer. Something like this

There are MANY threads on the forum about doing this correctly. It is vital that it is done too as without a proper live Z adjustment you are risking part detachment and its associated chance of then causing further problems or damage.

RE: Under extrusion first layer

Looking at that I think you have gone a bit too far. Once you get close the difference in fine tuning can be as little as 0.005. When too much squish you can get 'waves' where the nozzle pushes already extruded material along in front as its laying down the lines. That's what the artefacts you are showing now look like to me. J

If you aren't already use the Jeff Jordan method. https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/ old thread but a good one. As the thread is a bit massive now and it can be difficult to find stuff you could also use this https://www.printables.com/model/105404-calibration-strip-for-simple-live-zfirst-layer-cal created by another forum member here.

Just back it off in .005 increments until its smooth. Printing a 1 layer square or rectangle and adjusting it at different parts of the print gives you a quick and easy way to dial it in.

RE:

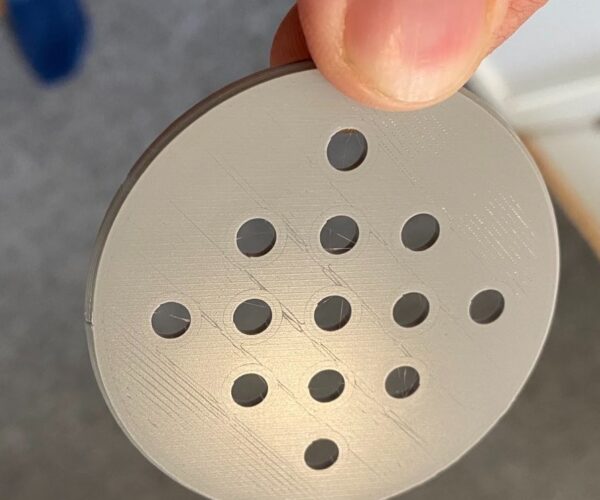

I tested -1.52mm and the result was slightly better, im now printing at -1.54 to see how that affects the print. The bigger areas look ok, it could be that the ripples after the wholes is a result of something else, and lowering the nossle isnt going to make them go away.

I did a live Z at this height, and its about as low as i think im able to go without squishing out the first layer too much.

RE:

It did improve slightly at -1.54mm, but my guess is that the ripples are from something else, perhaps temperature settings. Im not that picky with the print so i will go ahead and do my prints now. Thanx for the help!

RE: Under extrusion first layer

I was having the same issue and spent over an hour working on the Z calibration for PETG the other day. I would calibrate and things looked good but prints still had issues. I then followed this and found I had to adjust my Extrusion Multiplier by almost 7%. It may be the issue. From the two tests so far, it looks like it also made the walls better. I am learning and think this may become a standard procedure for me when I open a new spool of filament is to run this test with it. I will create a smaller test model for quick printing for initial tests.