Printing small cylinder - is this too small or too small a footprint?

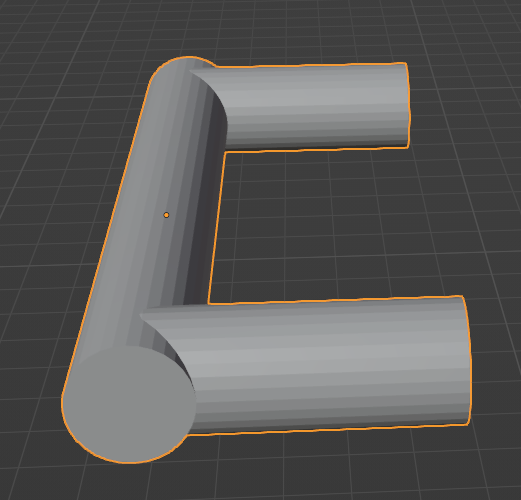

I want to print something that'll be used like a clevis pin. Here's a screenshot of a crude version just to show the shape:

It would slide through the holes in 2 adjoining parts with the two end pins sticking up, then, when in place, rotated so they would point down and hold the adjoining parts securely. I'll be printing these on a Prusa I3 MK3S+.

For scale, if possible, I was wondering if I could go as small as a 2mm diameter. This would make the one in this image, as oriented, 2mm tall, 6.15mm wide, and 14mm deep. (I'd probably shorten it to 4mm wide - shorten the end pins.) I could probably do these with a more square shape if needed. I'm mentally exploring other shapes ways to do this. I'm hoping to do this with minimal or no support.

I'm thinking the curvature is a steep enough slope so that might not be an issue. My concern is it's quite small. Is this too small to print? Is trying to print it without supports not likely to work? And any other suggestions, advice, or warnings about this that I should be aware of?

(Extra not-so-helpful info: My printer is in the workshop in the barn, about 500' away. I'm recovering from COVID and dealing with serious exhaustion, so, with the recent cold outside and the hill between here and the barn, it's hard for me to get there more than once or twice a day. Normally I'd print a number of test versions of this, doing multiple versions per test print, but going back and forth more than once a day, to check over test prints, is more than I can handle now, so I'm trying to eliminate whatever mistakes or issues I can clear up before doing test prints. Thanks for the understanding and help!)

That is very small - how big are the forces on the structure? It would print better if you could work with an octagonal cross section.

But you are close to the size where clipping off a length of raw filament would produce an equally good part.

Cheerio,

RE: Printing small cylinder - is this too small or too small a footprint?

That is very small - how big are the forces on the structure?

It supports a gooseneck that holds a USB or Pi camera. Although all the stress won't be on these.

It would print better if you could work with an octagonal cross section.

I can easily change to that.

But you are close to the size where clipping off a length of raw filament would produce an equally good part.

Good point!

I might be able to make the holes and use zip ties instead, but that can be a bit of a pain to place them and cut them off when the parts this fits into have limited clearance.

RE: Printing small cylinder - is this too small or too small a footprint?

You can certainly print a tube with 2 mm diameter but as diem said, I'd be concerned about the ability of it to stand up against any force.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Printing small cylinder - is this too small or too small a footprint?

You can certainly print a tube with 2 mm diameter but as diem said, I'd be concerned about the ability of it to stand up against any force.

Any suggestions about minimal size? It's under some stress, but not a whole lot.

RE: Printing small cylinder - is this too small or too small a footprint?

You can certainly print a tube with 2 mm diameter but as diem said, I'd be concerned about the ability of it to stand up against any force.

I've been thinking about this, on and off, since I read it this morning and kept thinking why this issue seemed so familiar. Then, this evening, it hit me this is a lot like the fittings and parts I've seen on my tractor. It's a smaller tractor and the bucket can hold between 1,000 - 1,500 lbs. It's held on by two metal pins that slide in cylinder connectors (one part of the connector is on the bucket, the other on the tractor). The slide-in connectors are thick and heavy. Then they have a hole in one end for something like a cotter pin or a similar fitting. I tried to find pics online of this, but all the parts pages focus on the big things, like engine and transmission.

Anyway, it's the heavy pin that carries the stress, but then a cotter pin or a ring pin (I think that's the term) is used to hold the main pin in. So the fastener itself is under low stress because it just keeps the pin that handles heavy stress from sliding out of its position.

I can use a similar design for what I'm doing - a thicker part that goes through the connection slot and something smaller that locks it into place.

RE: Printing small cylinder - is this too small or too small a footprint?

Any suggestions about minimal size? It's under some stress, but not a whole lot.

Not sure how to reply to this, as the only correct answer is "it depends"… depends on the actual amount of force and direction, and the direction the pin is printed in, the filament used, temperature printed at, layer height, etc. But *in general* I'd be nervous about going below 3 mm.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Printing small cylinder - is this too small or too small a footprint?

But *in general* I'd be nervous about going below 3 mm.

Would you say that 3mm is the "line," then? That if I went with something 3mm in diameter, I'd be in much safer territory?

There are no absolutes.

Because you are laying down lines of extruded plastic and the default width is 0.45mm there is only room for four full strands across - add another mm and it rises to 6 if there are enough perimeters set. Strength scales with the square so the extra mm more than doubles the cross section and strength.

Your part must maintan strength through a couple of right angles...

At this scale I'd be tempted to clip off a length of paperclip and bend it to shape.

Cheerio,

RE: Printing small cylinder - is this too small or too small a footprint?

At this scale I'd be tempted to clip off a length of paperclip and bend it to shape.

That's a good thought. A safety pin might also work, if it's the right length, since it could clip shut and not need bending.