Getting ASA to stick to textured PEI sheet using PETG.

Hi Guys,

Having issues getting eSun ASA to stick to my print bed.

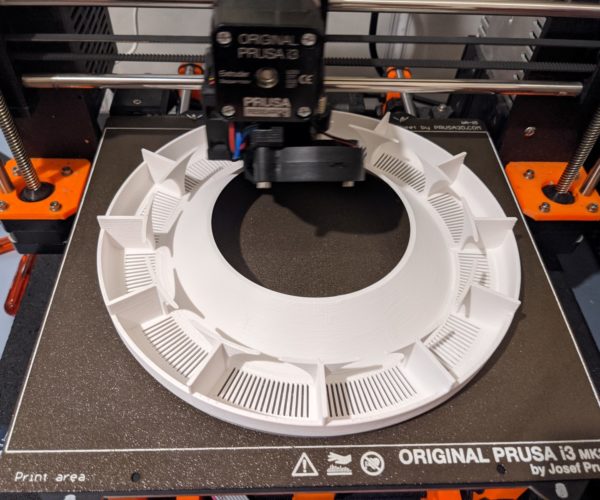

My solution was to add a 0.2mm solid layer to my print, and print that using PETG (setting the values for the first layer temps to PETG).

Then when the colour change is triggered at layer 2, I load the ASA and the temps increase.

What I've noticed is that ASA sticks very well to PETG when 110C. Then when it cools down the PETG releases from both surfaces, the print bed and the ASA print.

Just thought I would share, cheers.

RE: Getting ASA to stick to textured PEI sheet using PETG.

Cool !!!

thanks for sharing. Looks awesome. 👍

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Getting ASA to stick to textured PEI sheet using PETG.

Don't want to count my chickens yet, but I think I might just get my first successful ASA print with eSun filament. I've printed with other ASAs in the past and they stuck to the bed tenaciously, the eSun stuff seems a little softer and more slippery (if that makes any sense). Doesn't want to grip and layer adhesion isn't that great. Have upped the temp and extrusion width to try to compensate, will see how it goes. Just getting a successful print will be a start. This warpage on this was horrendous, it was enough to detach from the bed; yes I know it's not in an enclosure, it's on the list...

RE: Getting ASA to stick to textured PEI sheet using PETG.

A little advice regarding the enclosure. Try to keep the filament spools (especially PLA) outside of the enclosure, so the filament on the spool will not be heated by the inner enclosure environment and it will have chance not to melt earlier than required 😉

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Getting ASA to stick to textured PEI sheet using PETG.

@zoltan

Hehe, all good, don't use PLA, I use my printer as a tool not a toy 😛

PETG, Carbon fibre nylon, ASA. That's about it!

Hopefully the Prusa XL lets me print even more horrible chemicals 😍

RE: Getting ASA to stick to textured PEI sheet using PETG.

Well this ASA is horrible, all started to delaminate towards the top of the model. Layer adhesion was non existent. I had a play with the tube settings, seems to adhere at 285C (35C above the recommended max) and 110% flow. As this is a functional part, strength is more important than appearance. Number 2 printing now.

RE: Getting ASA to stick to textured PEI sheet using PETG.

Even with the a full skirt and printing at 285C is still delaminated in a few places. Hopefully when I get some Prusament ASA to test, they've added some secret sauce it improve the printability without the need for an enclosure.

RE: Getting ASA to stick to textured PEI sheet using PETG.

I think you are doing a really good job demonstrating the need for an enclosure...

Too bad. I really like your idea of printing ASA on top of PETG. Especially the self-release part.

Did you try turning the print fan off?

RE: Getting ASA to stick to textured PEI sheet using PETG.

I print gate handles from 3DX-Tech ASA at work in an enclosure with 0 fan and use Magigoo PC for bed adhesion on the PC sheet- has been working fantastically for quite a while now.

Anything can be made better

https://www.myminifactory.com/users/Joe%20Prints

RE: Getting ASA to stick to textured PEI sheet using PETG.

I print Fillamentum ASA on my Prusa I3 MK3S without an enclosure on a smooth PEI bed, I'm using Magigoo for PLA as bed adhesion agent. Parts are printed with a brim, so far every print turned out just fine.

RE: Getting ASA to stick to textured PEI sheet using PETG.

I print Fillamentum ASA on my Prusa I3 MK3S without an enclosure on a smooth PEI bed, I'm using Magigoo for PLA as bed adhesion agent. Parts are printed with a brim, so far every print turned out just fine.

Do you change print fan setting?

RE: Getting ASA to stick to textured PEI sheet using PETG.

@robert-rmm200

No change in fan settings, I used the default Fillamentum ASA profile which comes with Prusa Slicer 2.1.

RE: Getting ASA to stick to textured PEI sheet using PETG.

@mvalkier

Yeah so did I, bit even the initial layers had very poor adhesion. I'm printing bigger parts so using fatter layers and extrusion widths. Turning the heat up helped, but the geometry tends to lend itself to warping.

When I print with an old batch of black ASA I've had for ages it works fine. Seems to be more sticky.

RE: Getting ASA to stick to textured PEI sheet using PETG.

I printed PolyLite ASA onto the PEI bed at 105 c. The stuff stuck so hard I had to scrape it off with a razor blade scraper.

RE:

Thank you @Kenour. I was having difficulties with bed adhesion of eSUN eASA on the satin sheet. Your post gave me inspiration. TLDR: I ended up printing eASA on the smooth PEI sheet. For me that worked. Adhesion is much better than on the satin sheet. Removing the print was no problem. Of course any attempt you do to print eASA on the PEI sheet you do at your own risk.

Details

I was having adhesion issues with eASA on the satin sheet. I managed to print small models (2cm x 2cm) by setting the bed to 115 °C, printing at 260, heating the bed half an hour before the print so that the enclosure temperature reached 30 degrees, and I needed to add a brim. Even then I could print on the middle 1/3rd of the bed only.

I followed your suggestion of using the powder coated sheet, printing one layer of PETG, and then print ASA on that. That worked. This allowed me to print a large (20 cm wide) model almost without issues. (I'm confident that adding brim to the corners of the model would make it a total success.) Seeing how well I was able to peal the eASA of the PETG made me doubt if adhesion on the smooth sheet would indeed be so high that it would destroy the sheet.

I gave it a try. Using 240 degrees for the nozzle and 110 degrees for the bed as recommended by eSUN. I printed the 20cm wide model. This worked much better than printing on the satin sheet, which failed in the first layer with lines put down by the printer simply getting detached from the bed.

I stopped experimenting at this point. Again the print wasn't a complete success due warping in the corners which sharp edges. I think I could resolve this by adding a brim. However, I have no need to experiment further at this point in time. The small model I have already printed successfully. I found a commercially available alternative for the large model, which isn't that much more expensive than the price of the eASA. The only reason I tried the larger model in eASA on the smooth PEI sheet was to know if it would work well for potential future projects.

A set of 5x the smaller print on the satin sheet:

RE: Getting ASA to stick to textured PEI sheet using PETG.

I've had good luck with the PEI sheet and glue stick, with a brim. Sticks really well. Your PEI sheet will get bubbles and don't try to remove it until it's completely cooled or you can damage the sheet, been there done that. The glue sticks is good for 2 or 3 prints before you should clean it and reapply.