Drying filament info from knowledge base

I ran across https://help.prusa3d.com/article/drying-filament_332086 and I was wondering if anyone has ever had a need to do the suggestion with screws in Prusament spools (Section Prusement black spool) to keep them from expanding when drying?

I also noticed their recommended drying temp for PETG seemed a bit low at only 55C (for 6 hours). Most other suggestions seem to be in the 65-70C range.

RE: Drying filament info from knowledge base

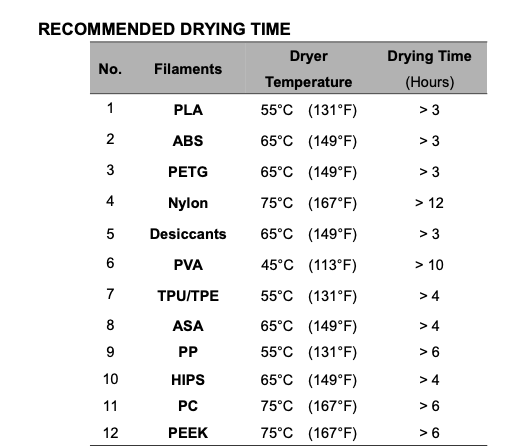

Never heard about the screw trick but also never had an issue drying black Prusament spools at high temperatures. I've been using the following temperatures, from my PrintDry Pro manual:

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

I was wondering if anyone has ever had a need to do the suggestion with screws in Prusament spools (Section Prusement black spool) to keep them from expanding when drying?

The problem doesn't arise with the lower temperature filaments, probably needed when drying Nylon for eg.

I also noticed their recommended drying temp for PETG seemed a bit low at only 55C (for 6 hours).

and this *might* be an example of deliberately keeping the temperature a little low to protect the spool.

I generally dry everything around 50C unless there's a specific need and I rarely time it; any drying is noticeably better than none.

Cheerio,

RE: Drying filament info from knowledge base

Before reading Prusa's document about the screw trick I had dried a couple of times my PC filament at 75C for several hours and the spools didn't fall apart, so maybe Prusa is being over cautious. Nevertheless, as I had screws of the correct size at hand, I installed them on my spools of PC and ASA, just in case.

RE: Drying filament info from knowledge base

I've simply dried any filament by leaving it in the air fryer on dehydrate setting overnight at 120F/49C. It's worked fine with PLA, PETg, ABS, and PVA.

RE: Drying filament info from knowledge base

I am curious about drying PLA - I weigh all my spools before and during the drying process. I've found that if PLA wet enough there's quite a drop in the first hour or so, often a gram or two disappears, but then nothing measurable thereafter. My conclusion is that only the outer windings are exposed to moisture and that "drying" for longer isn't doing too much. PETG takes a bit longer but nothing like 4 hours in my experiments.

FWIW I live in a very humid environment (RH 75%+) the driest of my dry boxes is at 20%RH

Never heard about the screw trick but also never had an issue drying black Prusament spools at high temperatures. I've been using the following temperatures, from my PrintDry Pro manual:

I ran across https://help.prusa3d.com/article/drying-filament_332086 and I was wondering if anyone has ever had a need to do the suggestion with screws in Prusament spools (Section Prusement black spool) to keep them from expanding when drying?

I also noticed their recommended drying temp for PETG seemed a bit low at only 55C (for 6 hours). Most other suggestions seem to be in the 65-70C range.

Filament manufacturers have different "secret sauces" in their brew so I am inclined to check each brand for recommendations on drying temperature. I've been drying Prusament PETG at 55 or slightly lower and weighing as above, around four hours is the longest I've needed to stabilise the weight.

If you are routinely drying and keeping the filament in closed storage with dessicant then yes, the outside layers are all you need to worry about.

If the spools are left out 24/7/365 then considerably longer drying will be needed.

Cheerio,

RE: Drying filament info from knowledge base

That is the case (storing in "relatively" dry boxes with dessicant), thanks for that confirmation of my observations.

I am always a bit reluctant to accept the advice of internet "experts" and always warn others that mine is no exception - my "findings" such as they are relate to my climate, my storage setup, and my inferior measuring skills and shouldn't be taken above the advice of the manufacturer!

Cheers!

P

RE:

I have not studied the drying properties, I just keep it simple.

Overnight in the air fryer set on dehydrate with a temperature of 120F/49C and it's always done the trick. All types, all brands.

I see that the chart above says to dry PVA slightly lower, but I've been doing it at 120/49 with no damage.

One thing I have found is that in at least one case, the brand of the filament makes a HUGE difference in the absorbtion from ambient air.

The name brand Ultimaker PVA can sit in room air for several weeks and print perfectly with no evidence of popping or stringing. The Dynamism house brand, however, will become damp and unusable in a few days and needs to be dried.