Any general hints for (reasonably) water-tight 3d prints?

Title says it all, actually. I have a project (outside in-ground pool alarm sensor) where I want to enclose one of those ultrasound sensors in a reasonably-watertight 'bubble', for lack of a better term.

I plan for two openings for the transducers and one small hole for the cable, but I would like to make the thing as water-tight as is practical.

I'm thinking things like 100% infill, ABS or PETg, and a tight-fitting lid, which will be sealed.

Any other hints or considerations for water tightness?

Thanks in advance, of course. 😉

RE: Any general hints for (reasonably) water-tight 3d prints?

I am curious and following you thread.

This might help:

https://all3dp.com/weekend-project-how-to-3d-print-watertight-and-airtight-containers/

I have printed a number of small containers to measure liquid chemical and have had no issue. I do not remember using 100% infill but I did use 6 or 8 parameter layers..

--------------------

Chuck H

3D Printer Review Blog

RE: Any general hints for (reasonably) water-tight 3d prints?

If I recall correctly, among the materials usually available for 3D printing, polypropylene is the best for water tightness. No need to use so many vertical layers. There's a caveat, though. Polypropylene is less dense than water, so it will float unless the part is glued/bolted somewhere or filled with heavier materials. Therefore, for this particular project, if the 'bubble' must remain at the bottom of the pool, maybe heavier filaments like ABS or PETg will be better.

RE: Any general hints for (reasonably) water-tight 3d prints?

Over-extrude, maybe? Get it good and sealed.

RE: Any general hints for (reasonably) water-tight 3d prints?

It appears that the paint on inside and outside seams are independent, so the outside seam and the inside seam don't line up.

https://blog.prusa3d.com/watertight-3d-printing-pt1-vases-cups-and-other-open-models_48949/

https://blog.prusa3d.com/watertight-3d-printing-part-2_53638/

Cheerio,

RE: Any general hints for (reasonably) water-tight 3d prints?

Thanks everybody.

The articles and discussion give some common-sense hints and also raise some questions.

I'm still leery of doing this with PLA, since it will be out in the hot summer outdoor environment. This particular piece will be enclosed, not in direct sunlight, but the enclosed piece may be more like an oven warmed by the sun. The cited articles discourage PETg, so I will probably go with ABS for this particular piece.

Thicker walls, dense infill, and higher extrusion rate seem to be universally recommended. 150% extrusion seems like a bit much, but a test print is very easy to do.

I think a coat of sealant inside is a good idea, and I will seal the top to the unit with a forgiving adhesive. Of course I will seal the hole around the cable.

I'll report back as to how this goes.

RE:

Just some quick feedback before I crash for the night.

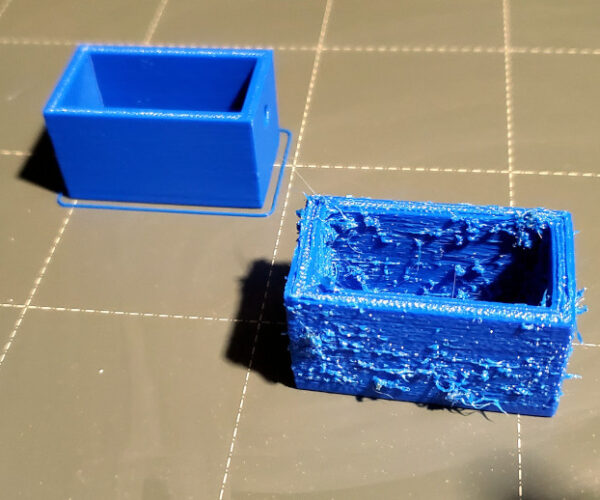

I decided to do a test print of the main part of the case using 100% infill and 125% extrusion.

If there's anything that the I3 does very well, it's printing little box type thingies in ABS so I did not think too much of it.

However, the results of this (below, right) can only be described as butt ugly. (Bad Print Hall Of Shame candidate?) I'm surprised it did not ball up in a mini Blob Of Doom or something. Much too much plastic extruded.

I then did a sanity check, just set everything back to defaults (Hatchbox ABS) and the result is to the left, below, and it printed as expected.

I'm currently running another test with normal 15% infill and 125% extrusion to see which parameter (or both) is causing this. I probably won't report back on that until tomorrow.

RE: Any general hints for (reasonably) water-tight 3d prints?

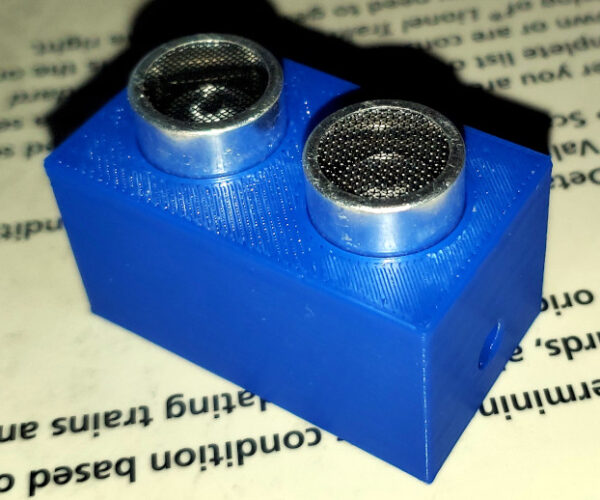

Here's another update.

This is in Hatchbox ABS using 125% extrusion and the usual 15% infill.

It appears that it was mostly the infill percentage and less likely the over-extrusion that was responsible for the zits and streamers and general ugliness of the one print above.

I will probably print the other part of the case this way, give everything a good coat of sealant, some RTV around the cable entrance, and call it good.

RE: Any general hints for (reasonably) water-tight 3d prints?

What are the silver things?

Here's another update.

This is in Hatchbox ABS using 125% extrusion and the usual 15% infill.

It appears that it was mostly the infill percentage and less likely the over-extrusion that was responsible for the zits and streamers and general ugliness of the one print above.

I will probably print the other part of the case this way, give everything a good coat of sealant, some RTV around the cable entrance, and call it good.

--------------------

Chuck H

3D Printer Review Blog

RE:

Those are the tops (bottoms in this project) of the ultrasound distance sensor. One is the transmitter and the other is the receiver.

They are very common and very cheap and often used in various 'maker' projects. Here's more info:

https://www.adafruit.com/product/4007

People have been using these for water level sensors for a number of years and they appear to hold up in the very humid environment. Even if it does not hold up, they are very cheap and less than US$5 for a replacement.

I'll probably do the code in c, but Python is commonly used with these as well.

I'll probably do the code in c, but Python is commonly used with these as well.

For my project, this will sit at the top of a tube which extends into the pool water and it will measure the distance to the water several times per second. Too much variation will indicate that something or someone is in the pool and set off an alarm up here in the house. I'll be using a Pi Zero to drive the thing. I could use an Arduino or Feather, but the Pi easily connects to the network and can trigger an existing alarm sounder on the main floor.

RE: Any general hints for (reasonably) water-tight 3d prints?

I haven't seen this detail, looks like a lego 🙂

RE: Any general hints for (reasonably) water-tight 3d prints?

I haven't seen this detail, looks like a lego 🙂

I sure would not want to step on it barefoot!