Re: Carbon Fibre

Excellent.

I will let you know how we are going once we get to printing.

Peter

Re: Carbon Fibre

I tried printing with TREED Carbonium PETG last night and failed.

I mounted a 0,8mm nozzle (a cheap one I bought in China)

Loaded the MK3 0,6mm presets and adjusted for 0,8, setting extrusion width to Auto.

Set temperatures to 60 for the bed and 240 for the nozzle, according to the data sheet from Treed, and volumetric speed to 7mm3/s

At first, when loading the filament it would not extrude, and I had to open the Bondtech gear, heat the nozzle to 260 and push it through by hand.

Then I tried printing. Treed states 230-250 nozzle temp, but I could not get a flow at all below 245, and it got better at 255, but still the nozzle would get clogged, and when I pulled out the filament, the last maybe 12mm were slightly thicker, indicating that it had been melted but stopped extruding.

One thing just came to my mind... the Chinese nozzle is more pointed,i.e. the shoulder around the nozzle opening is much smaller than on the E3D nozzle. Could that lead to a cold nozzle tip resulting in the clog??

See image here: https://item.taobao.com/item.htm?id=527795054818&toSite=main

(The price is in Chinese Yuan, that's less than 10 Euro cents for a nozzle...)

I'd appreciate your feedback and recommendations.

And specifically, what nozzle are you using for the CF filaments?

PS: I am fairly new to 3D printing, have printed mainly with PLA and PETG, with good success and also learned about trouble shooting.

I am a mechanical engineer with good technical understanding, which helps, but I have so far only used the standard settings and just starting to make more serious changes to the profiles.

I also printes a little in ABS and recently tried Hobbyking Polycarbonate with moderate success.

Printer is upgraded with the R3 parts.

UPDATE:

After studying the linked chinese seller's info more, it looks as if the inner cone on the nozzles has a much shallwoer angle and the material at the tip looks very thin. I assume that this could lead to high backpressure and following clogs. An indicator for this could also be that the extrusion coming from the nozzle when pushing the filament in by hand was very thick, which I take as a hint that the nozzle bore itselfs is likely to be very short.

Therefore I ordered a hardened 0,6mm steel nozzle from E3D, which also has the advantage of being able to use the Prusa standard printer profile.

Once again - buy cheap = buy two times 🙂

Re: Carbon Fibre

first successful carbon fiber ultem print (19mm wheel socket , 1/2" drive)

this thing should be printed in 200c chamber 😀 , my chamber temp around 50c , so the layer adhesion is probably bad .

0.5 nozzle , 390c , bed 130c (stock prusa bed) ,100% infill , raft was used .

Re: Carbon Fibre

first successful carbon fiber ultem print (19mm wheel socket , 1/2" drive)

this thing should be printed in 200c chamber 😀 , my chamber temp around 50c , so the layer adhesion is probably bad .

0.5 nozzle , 390c , bed 130c (stock prusa bed) ,100% infill , raft was used .

Be interesting to see what torque it can survive

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: Carbon Fibre

Be interesting to see what torque it can survive

will be testing that soon . i think it will be weaker then pla though (due to the reasons mentioned)

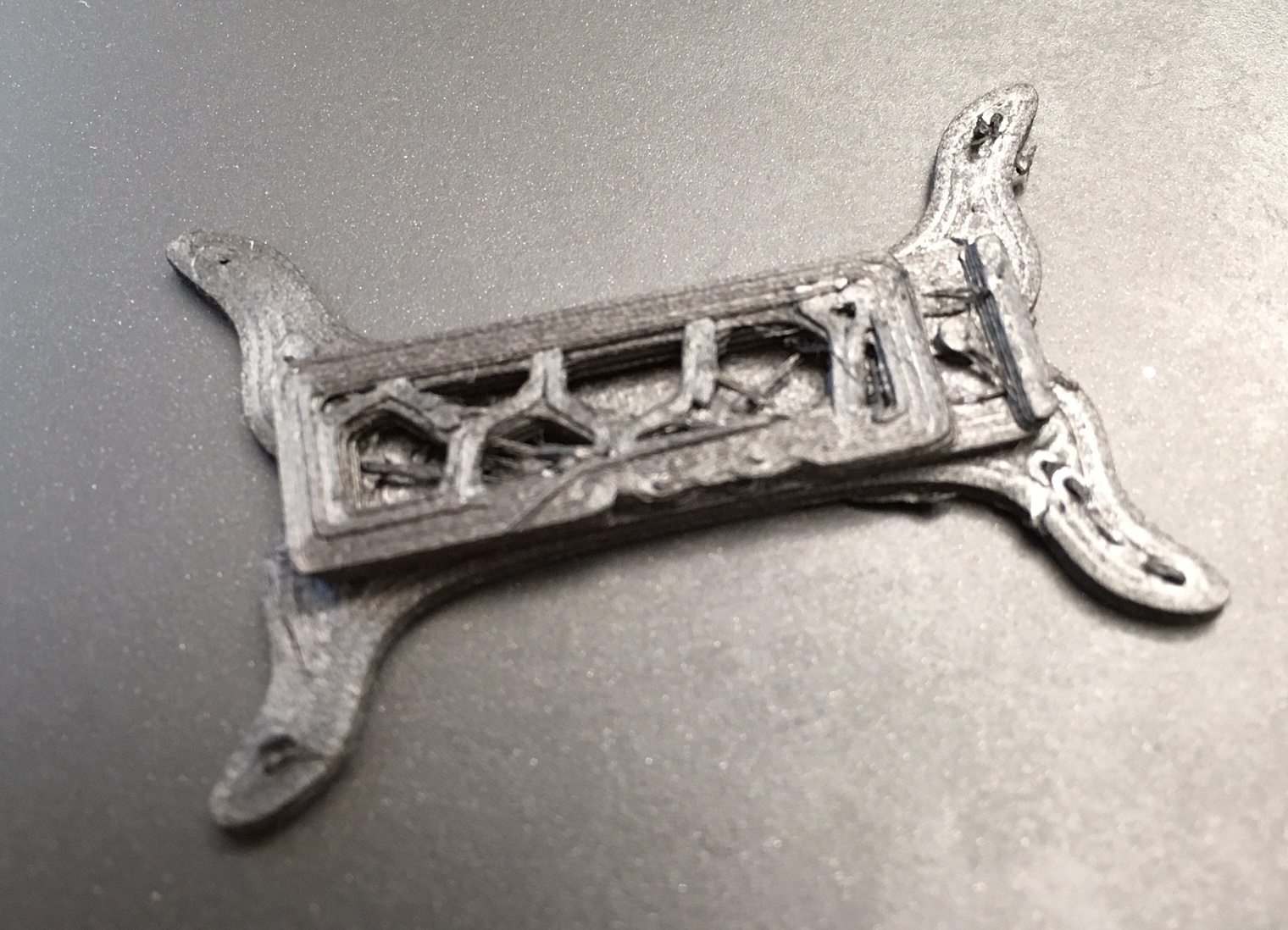

getting ready for heated chamber - carbonium extruder body (nylon) , slightly modified (pinda protection , threads directly on part - no inserts , bolts on lower section for rigidity , tighter clearance on filament entry for better flexible filament printing).

0.4mm/260c nozzle , 115c bed ,0.15 layer height

Re: Carbon Fibre

0.4mm/260c nozzle , 115c bed ,0.15 layer height

Interesting this is a 0.4 nozzle- previously you have said you prefer the .6

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: Carbon Fibre

Interesting this is a 0.4 nozzle- previously you have said you prefer the .6

you are right. actually i was using 0.5mm nozzle as i had clogs with 0.4 .

i stopped printing with 0.4 due to those clogs and the headache fixing them .but now i have some upgrades (like titanium heat break) and better profile so i went and tried with 0.4mm nozzle again , with no issues .

about the profile , i reduced retraction to 0.5mm-0.4mm (instead i set huge nozzle wipe , to around 20mm), and it seems that this is what solved the clogging issue .

i already printed with cf ultem and PAHP carbonium after changing my retractions and no clogs with 0.4 nozzle.

i'm also using very low layer height (for those filaments) of 0.15 and no clogs , i might try 0.1 later .

Re: Carbon Fibre

Hi Sergey,

This looks like the type of parts I would like to print.

Your parameters are very helpful.

Can I ask what if you are printing directly on PRUSA PEI bed or are you using something else?

Peter

Re: Carbon Fibre

Sergej, Great Print!! Would you mind sharing your config.ini for this material? And the exact type of nozzle? Is this an E3D hardened steel 0,4mm?

That would be great! Thanks in advance!

Re: Carbon Fibre

Hi Sergey,

This looks like the type of parts I would like to print.

Your parameters are very helpful.

Can I ask what if you are printing directly on PRUSA PEI bed or are you using something else?

Peter

directly on prusa pei with glue stick .

Sergej, Great Print!! Would you mind sharing your config.ini for this material? And the exact type of nozzle? Is this an E3D hardened steel 0,4mm?

That would be great! Thanks in advance!

e3d 0.4 hardened nozzle

added fff profile for 0.4 carbonium . please note my extruder multi is not calibrated (i dont care if it extrudes 10cm when i ask 9 , i adjust it per filament) so you might need to change yours accordingly .

also i upped the voltage on the psu to around 13.5v so i can reach bed temps up to 130c . if you cant reach those temps , 90c-100c is also ok .

no optimization in my profile for bridging or supports , i do manual supports most of the time .

there are also post processing scripts for lower acceleration (500 in this case) and custom start.stop scrips , please note those .

Re: Carbon Fibre

Thanks Sergej!

I just realized that you are using S3D and not Slic3r...

I'll try to transfer your settings to Slic3r, retraction is ok, but I didn't find an option wo set the wipe length.

It will take a while before I can try but I'll report back

Re: Carbon Fibre

Thanks Sergej!

It will take a while before I can try but I'll report back

Please do

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: Carbon Fibre

i checked in slicer , couldn't find any setting for nozzle wipe distance or coasting distance .

there is an option for nozzle wipe , without mentioning the distance of the wipe .

slicer pe is pla optimized , and with newer versions it will be more and more multi material (or more accurate , multi color) optimized .

Re: Carbon Fibre

Yesterday I received my E3D 0,6mm hardened steel nozzle and tried again to print with the Treeds Carbonium PETG.

I had major issues getting the filament to load and extrude, and only succeded after substantially increasing the temperature.

Tried printing a temperature tower starting at 265C, which is 15 °C above the range stated by TREED!

I had to slow down the print a lot to get a stable base, and the Z-hop produced a lot of whiskers, not really stringing, you can tell that there are fibers in the plastic which pull some material out of the nozzle when it is being lifted.

After printing maybe 3 mm high, the nozzle got clogged and the extrusion stopped.

The only idea I have is to disable Z-hop and try again.

Retraction is reduced to 0.5mm already, maybe I can reduce a little more, but the material is also oozing a lot.

I think Sergej is on the right track using wiping, but I could not find a way to influence the standard wipe of Slic3r.

ANY IDEAS AND SUGGESTIONS?

The material looks good otherwise, very stiff.

Re: Carbon Fibre

turn off z-hop .

dont be afraid to increase temps

i think cura has nozzle wipe distance setting , so maybe try cura .

why did you choose pet cf over the nylon ? try to dry it .

Re: Carbon Fibre

turn off z-hop .

dont be afraid to increase temps

i think cura has nozzle wipe distance setting , so maybe try cura .

why did you choose pet cf over the nylon ? try to dry it .

Thanks Sergej!

I have changed my settings, set Z-hop to 0, reduced retract from 0.5mm to 0.4mm and checked the "avoid crossing perimeters" checkbox.

I'll keep tring with Slic3r for the moment and if I can't get it to work I'll try with Cura.

I have no experience with Cura, so it will be a new tool to learn.

I chose the PETG simply for cost reasons, but I also have a roll of Carbonium Nylon.

I am glad I bought both, this way I can gather experience with the PETG filament before starting with the Nylon. This stuff is expensive 🙂

Here's the result of the temperature tower attempt

Re: Carbon Fibre

what is your layer height with 0.6 nozzle ? it seems too low .

Re: Carbon Fibre

Layer height is 0,2 mm

I tried printing with the changed settings yesterday.

First attempt failed after maybe 10 layers, clogged nozzle.

Increased temperature to 275, and successfully printed the first part of the temperature tower, but the nozzle got clogged again wile waiting for the temperature to drop to 270 for the next part.

Print looks quite good, but there's substantial oozing when leaving the perimeter, and bridging is so-so.

Layer adhesion seems to be good, but it's weak between the foot and the tower element.

Observations:

This filament oozes different to what I experienced before with PETG.

After loading the filament and extruding some into air, the filament keeps flowing for a long time after the extruder motor has stopped. I didn't measure, but several cm of fast flowing extrusion, then it slows down but still keeps flowing/oozing for a while.

There must be substantial pressure in the hot end that is reliefed when the filament is stopping.

I started printing extremely slowly, but increased the speed to 40mm/s later in the print.

The clogs seemed to be related to pauses in the extrusion, so I wanted to keep them short and keep the filament flowing.

I'm attaching my Slic3r settings and would be grateful for suggestions.

Below a photo of the most successful attempt so far.

Re: Carbon Fibre

0.2 layer for 0.6 nozzle is a bit too low (at least for starting out)

try 0.3 layer height , reduce your extruder multi by 0.1

and check again .

i never clogged 0.6mm nozzle , dont know how you do that . it might be due to different (weaker?) extruder motor on the mk3 or something else wrong with your extruder . above 270c petg will start to degrade .

tomorrow i'll try to make carbonium (nylon) profile for slic3r , but it will be for the mk2 ...

Re: Carbon Fibre

Thanks Sergej, you are the best! 😉

I will be on business trip for a week and won’t be able to try anything for a while, but I’ll think about it.

The extruder had been working fine so far, I recently updated it to the latest R3 version with better cooling.

The extruder motor is working a bit harder due to the larger diameter, and it does stop when the nozzle gets clogged. But one time it also ground into the filament, so it is still strong.

The only thing I could imagine is an issue with the PTFE tubes, but I‘d rather not disassemble the whole extruder again...

And when it gets clogged I manually push the filament through, and once flowing, the filament passes through quite easily. I‘ll gt back to it when I am back!