Underextrusion Flow Rate

After fixing a bad buddy board on my Prusa Mini I got the dreaded underextrusion issue that most people seem to have. I did as many of the forum users said and I adjusted the nozzle/hotend height, set my minda probe for proper height, cleaned the PTFE tube/nozzle and snugged everything back together. This helped a lot but I noticed I was still getting a bit of underextrusion. I started playing with my printer and noticed that after the initial purge line that the printer does at the start of every print if you go into settings it'll show Flow Rate at 95%. When I bump this value up to 100% I'm getting great prints.

HOWEVER, I was trying to see where to adjust this in the slicer so I do not have to try and catch my printer as it first starts the print to adjust this value. My research told me that the Extrusion Multiplier setting should be adjusted under Filament Settings in PrusaSlicer. My setting is at 1 or 100% but will always drop down to 95% after that first wipe. Is there another setting that alters this value? Am I the only one getting this? I greatly appreciate your input and look forward to hearing from users on this forum.

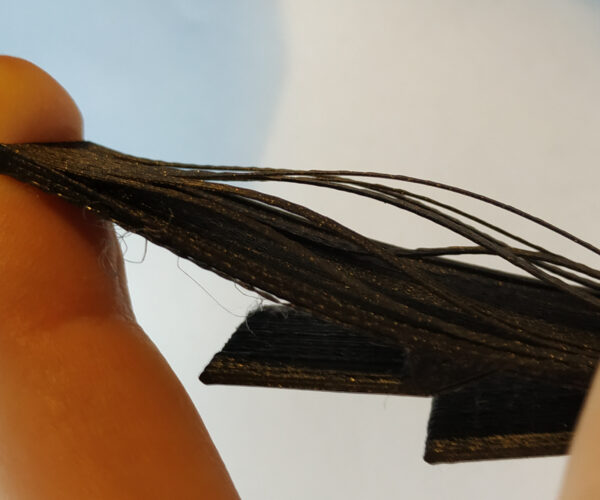

Below are photos of a print I did of a Tesla charge cable holder where I forgot to set the flow rate to 100% initially. You can clearly see where the poor extrusion is compared to when I bumped that value from 95% to 100%.

Best Answer by Neophyl:

Dont have a Mini but do have a MK3, in Printer settings> Custom G-code in the start gcode section there's a gcode command M221 that has the following -

M221 S{if layer_height<0.075}100{else}95{endif} - that sets the rate to 95 if layer height is greater than 0.075. If you change it there to 100 you will get the flow rate back to 100%

Have a look in your Mini profile.

RE: Underextrusion Flow Rate

I had the same problem.

After doing everything you described, I cut the speed to 75% in the Print>Tune Menu.

It is rather stupid, because the speed jumps to 100% for the next print, so that you have to adjust the speed every time you print.

After a test, 80% was too much.

RE: Underextrusion Flow Rate

@marek-3

Yeah, that seems to be an issue with successive prints, settings are resetting which is frustrating. Hopefully we will see a fix for this soon.

RE: Underextrusion Flow Rate

@charmande98

The underextrusion seems to be a real problem. This is out of the box. Tests after replacement of the inner tube and probe adjustment are similar. After decreasing the speed to 75% it is much better.

I have an old dolly (no smart trinamic motor drivers, PRUSA MK2 frame) which prints better and faster. I expected to get a new and precise printer for smaller pieces requiring good quality. After my experience I am seriously considering returning my MINI and buying MK3S instead.

RE: Underextrusion Flow Rate

@marek-3

Sorry to see such an issue. Yours seems to be really bad. I know you mentioned replacing the tube and adjusting the probe but did you also move the nozzle height? Also, what filament is that you're using? Just out of curiosity.

RE: Underextrusion Flow Rate

Dont have a Mini but do have a MK3, in Printer settings> Custom G-code in the start gcode section there's a gcode command M221 that has the following -

M221 S{if layer_height<0.075}100{else}95{endif} - that sets the rate to 95 if layer height is greater than 0.075. If you change it there to 100 you will get the flow rate back to 100%

Have a look in your Mini profile.

RE: Underextrusion Flow Rate

@neophyl

Thank you very much for this. The Mini profile shows the following "M221 S95; set flow" for Start G-code. I have changed this to M221 S100 and seems to be good to go.

RE: Underextrusion Flow Rate

I have noticed that the Flow rate is fine (95) for Prusament filament (in my case Galaxy Black) all my other filaments (All PLA) need a higher Flowrate (between 97 and a 100)

Stock MK4S with FW 6.2.6

RE: Underextrusion Flow Rate

Glad the M221 is good for you.

For the speed issue that looks like the intended function. When you change it via the front panel its for that particular print, although that is dependent on the printers firmware.

If you want to make it use a particular rate on each print then you could add M220 S80 into the start g-code section which will set the rate to 80% for example. That will apply to all prints sliced with that profile. Well it does on the MK3, I would be surprised if the Mini doesn't support that gcode though.

RE: Underextrusion Flow Rate

@oxygen

Its far better to measure the actual diameter of the filament (measure multiple points on a 1-3m length of filament) with calipers to find the average and then create a new filament profile to match with the correct value than to keep adjusting the flow rate. If the non prusa filament is slightly thinner then you are bumping the flow rate up to compensate which is the wrong place to do that, just set the filament diameter correctly and you shouldn't need to adjust anywhere else.

Prusa will have set the defaults for the printer with lots of real testing. If Prusament works good with the 0.95 flow then its a good bet that their real world testing used Prusament which isn't really a surprise, it being their in house brand.

Its generally good practice to create a new filament profile for at least each brand and often for different colours within a brand as they can vary.

RE: Underextrusion Flow Rate

That is what I am doing, I have created a 30 x 30 x 1 calibration square, and create profiles for every brand of Filament that I have... The Thing I have noticed yesterday evening (and needs further investigation) is that after a successful print when I reprint the Flowrate is different then when the printer just booted (or reset)

Stock MK4S with FW 6.2.6

RE: Underextrusion Flow Rate

@charmande98

Yes, I moved the nozzle up, the final distance from the fan body is now 3.95 measured with a caliper. The space for the tube is clean, checked with a small endoscope. Then I readjusted the probe. First layer compensation at 0,850.

I use Prusament PLA Galaxy black. With 75% speed it is basically OK, however the strength between the layers is still poorer than on the parts printed on my Dolly with almost three years old filament (filamentum, a presume), never kept in a dry bag.

I also use Gembird PLA+, which gives just tragic results. It disintegrates under the weakest possible pressure.

I tried playing with temperatures, speeds, flow and layer thickness, the whole array up (down) to 230°C, 50%, 110% and 0,10 respectively with no success. I admit, it can be just a bad filament. But still...

I am using the PRUSA face mask pozicer as a test product now. I know, it is just two layers thick, it is ambitious, it is meant for PETG, but I cannot accept being able to get better results from a three years old Dolly, (in fact a ball of wire on a desk) run by a laptop via USB, with three years old filament, than from a new brand printer and a new dry brand filament.

I am not complaining, just my expectations were rather high after reading "out-of-the-box experience" reviews.

RE: Underextrusion Flow Rate

@marek-3

I agree 100%. Based on the many out of box reviews I saw I thought the Mini was going to be great out of the box when I received it. This is 100% not true considering the amount of time I've had to fiddle with this device. The prints are coming out amazing but thankfully I was persistent and also had experience. I could not recommend this to a new user given the level of in-depth adjustments I've had to pursue just to get okay prints. Oddly enough even little things like preset profiles seem terrible in certain regards (ie I bought Sainsmart TPU and used their preset profile and the prints look like absolute trash, however select generic FLEX and they come out great), which can be very confusing to beginners. Prusa will surely make this better as they've already made several advancements. Hope you get some great results as well, just keep at it! Best of luck.

RE: Underextrusion Flow Rate

@neophyl

Thanks man you've been absolutely amazing. I'm all fixed up now and finally getting some great prints out of this printer.