Slow print speed causes underextrusion and stringing

Printing eSun PLA+ on my Mini+ at 225 C. I noticed lots of stringing and bad surface area on certain sections of some prints. Did some testing and found out that these problems appear on sections that have the print speed slowed down by autocooling to about 15 mm/s. Raising the minimum print speed in autocooling settings to 25-30 mm/s significantly reduces the rough surface (underextrusion?) and stringing, no idea why. I know reducing the temp will further reduce stringing, but that is not my goal.

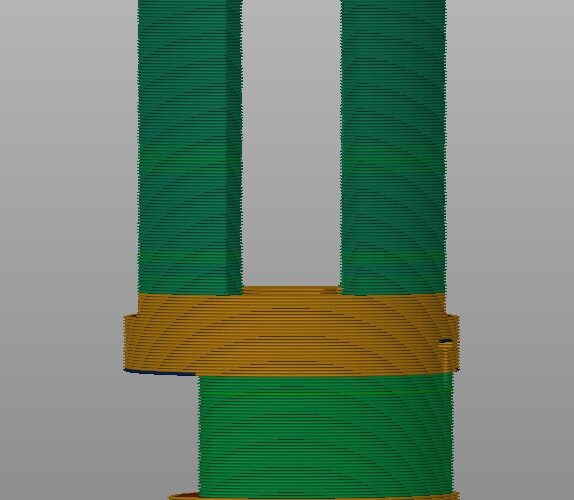

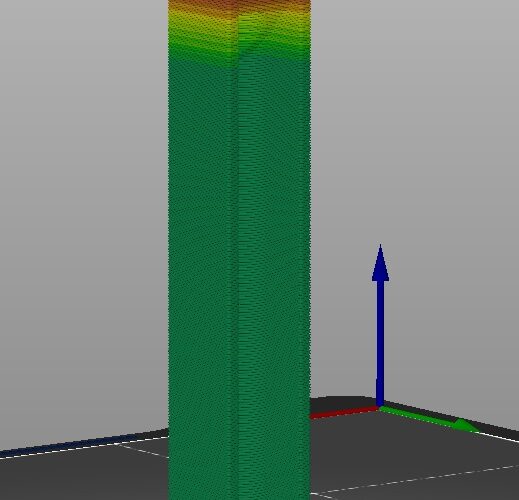

Notice the simmilarities between parts and slicer speed diagram:

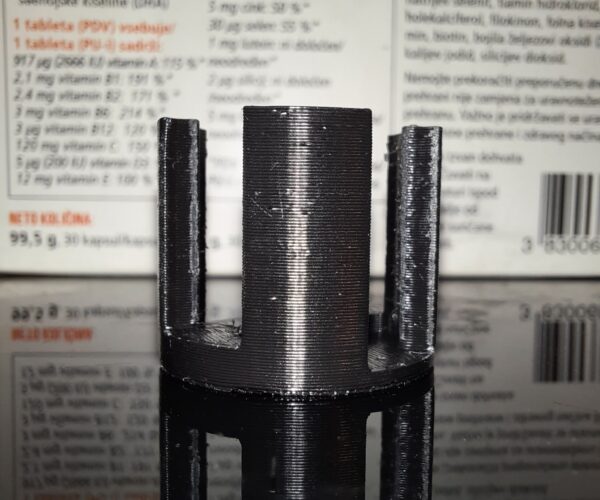

Same section printed with 30 mm/s minimum print speed:

RE: Slow print speed causes underextrusion and stringing

Did some more testing today. Dropping the nozzle temp to 210-215 fixes the extrusion problems and stringing at slow print speeds. My theory is that at slow print speeds the filament spends more time in the nozzle and starts to overheat before leaving the nozzle, that's why it only happens at low print speeds. So the solution would be to manually lower the nozzle temp in gcode at sections that have entire layers slowed down by autocooling. Looks like I just discovered heat creep lol. Time to upgrade the stock heatbreak I guess. I hope it will enable me to print the slow speed autocooling sections at 225 C.