Seems very inconsistent

Just received and built my new Mini+. Got live z reset to a good looking first layer on the Prusa Plackard on the provides USB. Managed to print a few other pieces with decent results, a Marvin I sliced in Prusaslice (default PLA, .2 and .1 quality), and the Nut/bold on the USB.

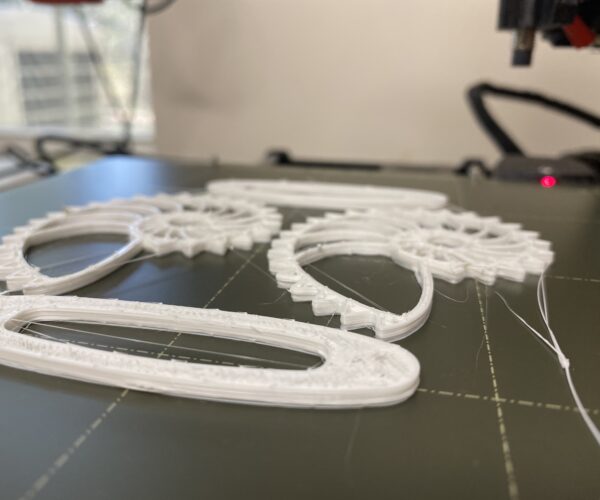

But I'm really struggling for any real consistency. I get some random blobs in the middle of a solid layer big enough to jam nozzel on next layer. Random clogs causing the extruder to click, have to do a cold pull. Or I can't get first layer to adhere consistently, despite a decent looking layer. I've tried individually changing flow rate, bed temp, nozzel temp, switched to a new pack of PLA so I knew it was dry. Maybe I get one that works, maybe not.

Can't get 2 prints in a row to really narrow down any specific issue, so don't know where to start, and getting frustrated.

Where do I start to narrow down what's wrong?

RE: Seems very inconsistent

try making a large flat print model only a few layers thick, set it going and as its filling the layers in see if theres any common areas it fails on.

I did this to pin down problems i had that looked similar to your 3rd picture, where i discovered if there were large areas of infill running at 80mm/s it extruder clicked and skipped big chunks. slowing the print as it was going highlighted the success of it at lower speeds - it lead me to create a printer profile where its infill speed is slower.

having a reliable predictable shape test like this allows you to live mess with a lot of the settings to tune in the issues, some stuff obviously is not included while its printing (retratcion etc) but it does sgive you a predictable output to gauge your results on.

stuff that helped me with inconsistent pla printing:

1) increasing the nozzle temp (i print at 220 pretty much all the time, with jumps to 225 and 230 depending on the print and how far thru the spool i am)

2) slowing the printer speed down - either on the fly or in the slicer, eventually i changed my default 'quality' profile to have slower infill speeds to ensure i didnt have to babysit the prints

3) increasing retraction to 5mm

4) increasing flow rate to 100 past the base layer - i messed with this setting a bit in part of the under extrusion diagnostics, once i had the above dialed in i returned the flow rate to defaults

RE: Seems very inconsistent

@remington

Had a really nice looking cold pull come out, made sure extruder gear was clear. PrusaLogo block off the USB to eliminate slicing issues. Using the PLA I opened this AM, indoors, IPA washed sheet, 80% speed, upped nozzle temp 5 degrees to 215 - and just not getting anywhere. First half of first layer looked good, then it clogged again.

I'll give it a rest, try again another day. Just truly disappointing after waiting 2 months, and just can't get it rolling.

Thanks for tip, when machine and I have really cooled off, I'll take another pass at it.