Printer stops near the end

Hi All,

I’m having issues with my print— for whatever reason towards the end of my print, the extruder stops and/or there is weak infill and/or there is blobs and zitts that appear.

If anyone could please help, I’ve attached images and my print settings. I’m also ordering new parts but want to diagnose the root of the issue.

Thank you all.

Best Answer by Lupin:

Check the "classic case" filament profile in the slicer vs what you have actually loaded into the printer.

Looks like all kids of printing defects on the parts. Stringing within infill? What filament are you using and how long has it been since last drying/taken out of the original packet?

I would guess for PLA and a seriously wet roll at that. The water in the filament will turn in vapor when heated and that causes also spitting when the suddenly expanding vapor pushes molten filament out of the nozzle. Naturally if the slicers filament profile does not match your actual filament, all bets are off...

The last piece looks like the lamb which I have printed with PETG without issues and I imagine seeing spitted plastic on the back of it.

With wet filament the water vapor will take large volume in the hot end, and that will cause too little filament to be output. Why that would stop printing is beyond me, I can come up with this theory: The expanding vapor causes pressure in the hot end and blocks the extrusion so the printer stops in a jam.

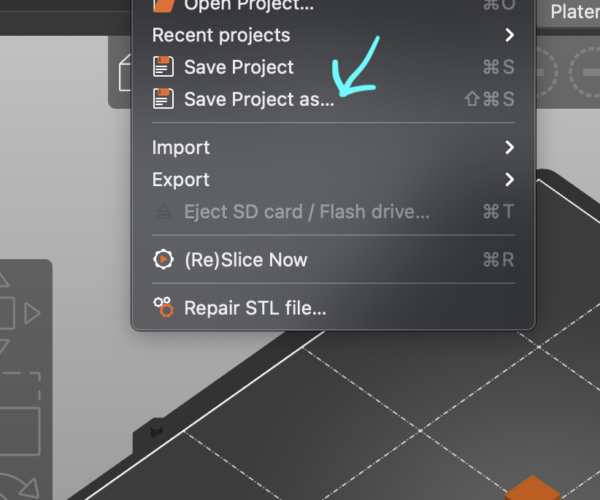

3MF

Can you upload a 3MF file and which filament are you using? It will allow us to better understand what you are doing.

--------------------

Chuck H

3D Printer Review Blog

project file

3MF files are files that include the whole project so we can see your settings.

--------------------

Chuck H

3D Printer Review Blog

From the picture

Check the "classic case" filament profile in the slicer vs what you have actually loaded into the printer.

Looks like all kids of printing defects on the parts. Stringing within infill? What filament are you using and how long has it been since last drying/taken out of the original packet?

I would guess for PLA and a seriously wet roll at that. The water in the filament will turn in vapor when heated and that causes also spitting when the suddenly expanding vapor pushes molten filament out of the nozzle. Naturally if the slicers filament profile does not match your actual filament, all bets are off...

The last piece looks like the lamb which I have printed with PETG without issues and I imagine seeing spitted plastic on the back of it.

With wet filament the water vapor will take large volume in the hot end, and that will cause too little filament to be output. Why that would stop printing is beyond me, I can come up with this theory: The expanding vapor causes pressure in the hot end and blocks the extrusion so the printer stops in a jam.