Print keeps lifting off bed after a while

Hi y'all,

Trying to troubleshoot a large problem I'm having as I've been printing PETG lately. A while back I've had what I think is unrelated issues regarding the PETG filament getting jammed in the feeding box, which after a while of not realizing how to use the idler screw and jamming filament over and over again, I have hopefully fixed resulting in the filament getting easily inserted. I'm not entirely sure if this messed up retraction, however, as I've printed 5 parts over the course of the past couple of days that have had major stringing and came out really dirty. However, this pales in comparison to the problem I've just had 3 times in a row on one of the prints. Basically during the middle of the print, I start hearing a peeling sound, followed by extruder dragging the entire print with it and hence not making any progress. Footage can be found here: https://drive.google.com/file/d/1e1UB6r3aDvdGtad8GTELlZ4lRAN5wzhF/view?usp=sharing

Letting this go makes it much worse obviously and it led to some really hall of shame worthy results (image attached). I have a couple theories for why this is happening but I'm not entirely sure. Could anyone shed some light on whether this is a common problem as I haven't been able to find any support for it online. Thanks a bunch y'all!

Best Answer by Alias72:

-2.00 is the max offset of the printer. If you are at -2.00 it suggests that your PINDA sensor is affixed too low on the head and you have an insufficient z offset. This can be easilly adjusted by loosening the retaining clip holding the silver threaded part and lifting it a thread or two. Tighten the screw and repeat the bed calibration. DO NOT re-use the existing calibration. It will ask if you want to start from scratch. Say yes. Try increasing the z offset until you get a solid square at the end of a succsessful calibration. If the calibration fails then do not attempt a real print, instead, repeat calibration with different z offsets. Don't be afraid to change the z offset while the square is printing to find the correct position. Just remember what heights were used where.

sticking

I am pretty sure your z offset is off.

I recommend you:

- Clean the bed with Dawn and a sponge.

- Do a first layer calibration and post an image of the square.

--------------------

Chuck H

3D Printer Review Blog

RE: re

I did think that was the problem at first, so I changed back from what I originally had to be -2.00 to -1.9 but this just made first layer worse. I also do do windex wipes after every print for less strong adhesion, and this shouldn't be a problem(?) Attached is the calibration print at -2.00. Square seems really perfect though, like the first time I've calibrated, For some reason there's just this extra blob that gets dragged along that seems to be stringing, but I'm not entirely sure what causes this. Might be a dirty nozzle, as it is really brown and dirty, but I don't have a wire brush to fix this atm.

RE: adding notes

It seems like roughly the prints fail at around the same time too, around 40 minutes in. I'm worried that this is probably a problem of the gcode being invalid (like one of the first problems I've had) and forcing the extruder to dip into the build and causing it to pick it up, but I don't see any weird z changes shown. Still somewhat lost though

BTW, I am using the PrusaSlicer default PETG retraction settings, so I'm not entirely sure why the stringing is happening (might be related to this or a previous topic where I might've messed up retraction)

I suspect you have two problems...

First, clean the print bed thoroughly, Dawn/Fairy and lots of HOT water, dry with paper towels and hold by the edges only - THEN reduce adhesion with a spritz of window cleaner.

If you have not yet done so, enable 7*7 mesh bed levelling.

There is enough fine stringing in your pictures to suggest your filament is damp. PETG absorbs atmospheric moisture easily and only a couple of days in high humidity can cause problems so dry your filament (plenty of threads here.)

Cheerio,

reply

Ahh okay, so that's as I figured. I live in Florida which is a very damp area and I haven't put it in any containment box for about 2 weeks, so this does definitely make sense; I just figured it wouldn't be as bad since some sources said PLA and PETG are equal in their moisture absorption. That makes a lot of sense though; I'm going to get a filament dryer and hope it will be better now. Additionally, should I assume that the retraction and other settings are relatively fine, then?

PLA absorbs moisture too. Here (southern UK) we just had a couple of weeks of high humidity and both PLA and PETG have needed drying. Some filaments absorb water faster than they can be printed so for you, nylon may have to be printed directly from the dryer...

should I assume that the retraction and other settings are relatively fine, then?

Don't change any settings until you can test with known good filament.

Cheerio,

Re

Maybe something stuck on nozzle? I've had issue with something like that and I had too much filament stuck on nozzle area.

RE: update

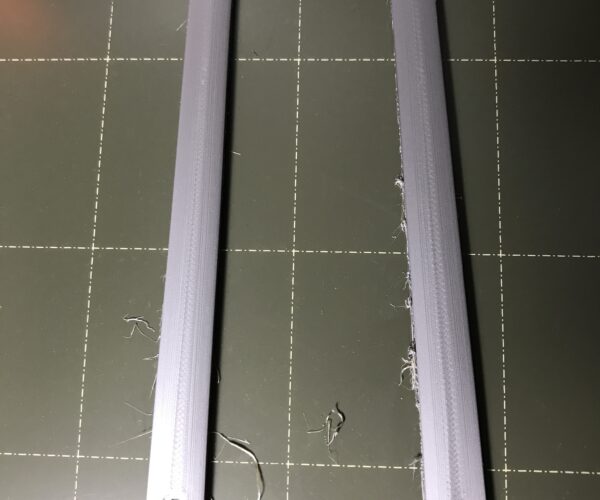

Yeah, so actually I've done a couple prints recently and they're still relatively stringy. @jmh714, this might be the slightest bit true. I did clean out my nozzle, but there's just so much on it that I can't really identify (picture attached), I think it's probably burnt plastic, but I can't seem to get it off with my fingers so I'm planning to get a wirebrush to at least set this more straight. I'm not sure if this is actually the problem though, so I'm not that optimistic on this.

This is a new print that I made recently with the filament heater running throughout the print, and as seen it still looks very stringy:

RE: (why I have to enter title every time I add a reply????)

Yeah, so actually I've done a couple prints recently and they're still relatively stringy. @jmh714, this might be the slightest bit true. I did clean out my nozzle, but there's just so much on it that I can't really identify (picture attached), I think it's probably burnt plastic, but I can't seem to get it off with my fingers so I'm planning to get a wirebrush to at least set this more straight. I'm not sure if this is actually the problem though, so I'm not that optimistic on this.

Probably not. I never seen like that before (regarding the picture).

I would suggest when you clean the nozzle - heat it up first, so the filament can become soft and pick it with tweeter and then use wire brush.

RE: (was wondering this too)

Yeah though, I tried that a slight bit, but was really unsuccessful which made me to believe it was probably discolored steel, although this seems infeasible. However, I've pulled a roll of PLA filament that had been sitting simply in a box, not sealed or otherwise humidity controlled, and with the same uncleaned nozzle (plus the filament heater), and it seems to be working more or less perfectly (some areas that I absolutely expected stringing still are, but this is mostly regular although could be fixed with some better settings). So I don't think it's necessarily the nozzle, just that I can't seem to print PETG (at least with the current settings).

I'm entering standard title

I saw a thread in General discussion (in Mini+ section) that someone couldn't print PETG on steel sheet. Maybe that explains?

I have MK3S printer that prints PETG on steel sheet with no issue. I haven't tried print PETG on my new Mini+ yet.

same

Yeah, I don't think the issue is the sheet unfortunately, mainly because the first layer comes out really well actually. Most of the problem seems to happen after the first couple of layers, when the layers start getting rough for some reason (image attached). Additionally, adhesion is perfect on the steel sheet with a few spritzes of Windex, so I'm inclined to believe it's not that. It's really unfortunate though, since pretty much all of my PLA filaments print with barely any scratches.

Windex is not needed with PLA. That print sure looks over hydrated. Too stringy. Have you tried a different filament?

--------------------

Chuck H

3D Printer Review Blog

sorry, should've clarified. I meant I used Windex with PETG, and yes that seems to be what happens with any of the PETG filament I've used, even tho I've run it through a filament heater. The other spool of PETG I've used was transparent, so I didn't get to see any details of it and I think it would probably have a similar problem since they've been left in the same conditions for about the same amount of time.

How to enable 7*7 mesh leveling?

I suspect you have two problems...

First, clean the print bed thoroughly, Dawn/Fairy and lots of HOT water, dry with paper towels and hold by the edges only - THEN reduce adhesion with a spritz of window cleaner.

If you have not yet done so, enable 7*7 mesh bed levelling.

There is enough fine stringing in your pictures to suggest your filament is damp. PETG absorbs atmospheric moisture easily and only a couple of days in high humidity can cause problems so dry your filament (plenty of threads here.)

Cheerio,

How do you enable 7*7 mesh bed leveling on the MINI+?

Are we having a similar problem?

My printer keeps knocking my build over after a while:

How do you enable 7*7 mesh bed leveling on the MINI+?

Oops, sorry. This is such a common issue that I keep a prewritten text to copy and paste from; sometimes I fail to check for which model I am replying.

Cheerio,

Adhesion

Most of the time, adhesion issues are related to a dirty bed or a Z offset being off. This includes when prints are being knocked down.

--------------------

Chuck H

3D Printer Review Blog

Z offset

-2.00 is the max offset of the printer. If you are at -2.00 it suggests that your PINDA sensor is affixed too low on the head and you have an insufficient z offset. This can be easilly adjusted by loosening the retaining clip holding the silver threaded part and lifting it a thread or two. Tighten the screw and repeat the bed calibration. DO NOT re-use the existing calibration. It will ask if you want to start from scratch. Say yes. Try increasing the z offset until you get a solid square at the end of a succsessful calibration. If the calibration fails then do not attempt a real print, instead, repeat calibration with different z offsets. Don't be afraid to change the z offset while the square is printing to find the correct position. Just remember what heights were used where.