How do I prevent organic supports from failing?

I've recently switched from default supports in PrusaSlicer to organic supports and I'm really loving the time and material saved, the design is really fantastic.

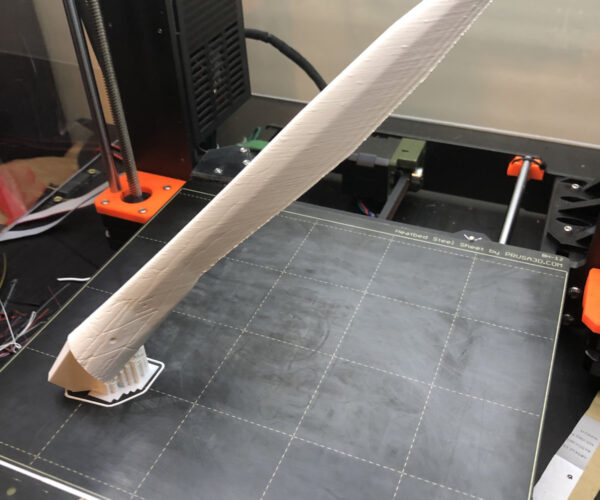

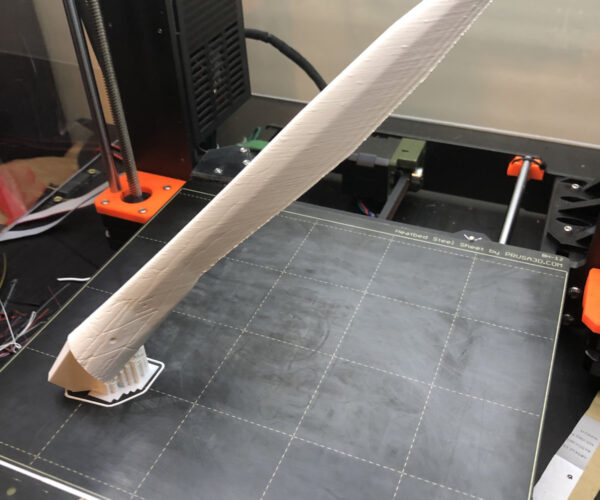

Most of the time, the supports print without any issues but every now and then they seem to get dislodged midway through a print which ends up in a pretty bad failure like this (printed earlier this evening):

I'm usually in the room during the whole printing process but I have always missed the beginning of the supports breaking so I'm not sure what is causing it. The first sign is probably a minute or so later when I hear the nozzle and/or sensor colliding with the dislodged supports.

My settings look like this:

I'm not sure what is causing this error but I would really like to troubleshoot it so I can create successful prints in the future with organic supports.

Has anyone else had any issues using organic supports? Is there anything I can do to strengthen/widen the support structure slightly to hopefully prevent them from collapsing mid print?

I've attached the model I'm trying to print, here it how it looks with organic supports generated using the settings above:

Best Answer by Neophyl:

Thanks for attaching the project. Its the quickest way to get help on the forum as everything is in it. Its also good to save them in normal use as it allows you to revisit later and tweak settings, even years later.

If you set supports For Enforcers then you wont get any support. Until you define areas to support. The Everywhere option puts too many, it is VERY conservative.

The Paint tools for support work great. The Automatic Painting works quite well too although it can also be a bit conservative and adds support to areas that dont need it. The Smart Fill tool is great and makes painting specific areas much easier in general (if the model geometry is good).

So yes I generally will set For enforcers only and then paint on the areas I want. Sometimes I will use the Auto Paint button in the paint tool, see what the slicer thinks and then remove some of its choices using the shift and left mouse button to remove the painted on enforcer. Other times I might even add a bit of painting to cover a larger flatter area where I know I want a larger support area. Generally though I know what areas need it just by looking at the model. Slicing it and looking at the dark blue extrusion in the preview is also a good habit to get into. Actually going through the preview EVERY time is also a good habit to get into looking for possible issues.

One other tip, is the support interface layer. I often set that to 4 layers on top and zero on bottom. Probably not needed on this model but when you are supporting a large flat area by having more layers it makes the interface layer thicker which can actually make it easier to remove in one peice, rather than it breaking up as you are removing it and you having to pick it off in bits.

Those areas you circle in black will print fine without and support. While the angle does increase to overhang height, assuming you are printing hot enough to get good layer adhesion the slight overhang perimeter will adhere and at the top of the arch it will be bridging anyway. While a couple of perimeter sections will droop ever so slightly inside there they arent long, are supported at both ends and the surface in there wont be worse and is usually better than what you get when printing on supports.

If you examine the slice preview closely in that area you will see that the support generation is probably CAUSING issues rather than helping with them.

Look closely at the dark green interface layer extrusion. Most of it is in 'mid air' and not supported by the organic supports under it. This is going to be messy and curl up. At that point its likely to be hit by the extruder.

Look closely at the dark green interface layer extrusion. Most of it is in 'mid air' and not supported by the organic supports under it. This is going to be messy and curl up. At that point its likely to be hit by the extruder.

You could cut the model down using sinking and the cut tools to isolate just one of those arches and print it just as an experiment. I think you will be surprised at what is possible.

For example just to show what good bed adhesion and an overhang is capable of.

Other general tips, this is a functional part as its a spool holder. More perimeters gives a stronger print than increasing infill.

I've attached an updated project based on yours with how I would print it. Personally Id check the arch/hole print with your specific material but using the cutting technique (also included in the zip file hopefully) before printing the entire thing. Doing just the arch is less than 15m and would be worth it.

RE: How do I prevent organic supports from failing?

Looks like you have not attached the model (zip it and upload a zip).

I had issues when my filament was not dry and oozing was causing blobs on the heat end and this was causing damages to the supports when print head was moving around.

See my GitHub and printables.com for some 3d stuff that you may like.

RE: How do I prevent organic supports from failing?

Sorry - I've attached the model to this post (hopefully)

RE: How do I prevent organic supports from failing?

We need your project file. The model on its own is very little use. We need you to slice it and then use File>Save Project as. That will save a PS 3mf file. the 3mf will contain all your settings and allow anyone to slice it identically to you. What material are you printing with for example. I presume a mini given the forum we are in but what layer height ? The settings you are using are far more important.

Yes I know you pictured your support settings but you haven't included the settings for Organic support which are below the settings you did picture, what about your extrusion widths ? Are you using auto settings for support ? have you painted any specific enforcer areas? , added a blocker ? Do you have z lift enabled ? or any of the hundreds of other things. With a project we get all that, a complete picture.

If I had to guess then I would suggest increasing the extrusion width for supports. It appears you are using default settings and by default extrusion width for a 0.4 nozzle uses 0.35 as the extrusion for support printing. This is to make supports weaker and more easier to break apart. This setting tends not to work well with tall organic support unless your printer is dialled in well or over extrudes naturally. Setting it to a more normal 0.45 width extrusion works better but does use a bit more material. Also most of that model doesn't need support and so you are wasting material supporting areas that don't require it anyway.

You might also want to examine the Branch Diameter with double walls setting. Making it lower to force double thick walls for thinner branches.

PS If a part that size requires a brim then you have something up with your bed adhesion. Is the tree support detaching from the bed when the extruder clips it or is it just breaking apart? Can really tell from your picture either.

I don't have a mini profile installed currently but I've attached a sample project for a basic Mk3 for you to examine. It uses painted on support enforcers rather than auto supports and modified organic support settings as well as a normal extrusion width. If you do attach a project file we could modify that as an example and you wouldn't have to change anything then to slice it for your printer.

RE: How do I prevent organic supports from failing?

Thank you very much for your reply - my sincere apologies, I have re-created my slicer settings with this model and attached the project file. Hopefully this includes all the important info -

When slicing I always opt for building supports 'Everywhere' - perhaps I was wrongly advised but the slicing tutorial I initially watched advised doing so in order to minimize print failure.

I have in the past tried to use 'For support enforcers only' but that doesn't seem to generate anything -

I only normally use brim for small models - on this occasion it was unticked but it seems to have been added when the supports were automatically generated. I never usually have any issues with adhesion, even with smaller models - the supports adhere very well to the bed but just seem to break mid-way through the print. This has only happened since I switched to organic supports - the traditional/default supports I previously used were always fine.

Thank you very much for the tips and insight, it's given me a lot to think about and tinker with. Please could I just ask:

1. What is your general approach to custom supports? Do you manually paint them on for each model where you deem them necessary structurally or do you have preferred settings that you use for most models within the Paint-on supports GUI?

2. When adding supports to this model, would it not be necessary to add them for these parts circled in black?:

RE: How do I prevent organic supports from failing?

Thanks for attaching the project. Its the quickest way to get help on the forum as everything is in it. Its also good to save them in normal use as it allows you to revisit later and tweak settings, even years later.

If you set supports For Enforcers then you wont get any support. Until you define areas to support. The Everywhere option puts too many, it is VERY conservative.

The Paint tools for support work great. The Automatic Painting works quite well too although it can also be a bit conservative and adds support to areas that dont need it. The Smart Fill tool is great and makes painting specific areas much easier in general (if the model geometry is good).

So yes I generally will set For enforcers only and then paint on the areas I want. Sometimes I will use the Auto Paint button in the paint tool, see what the slicer thinks and then remove some of its choices using the shift and left mouse button to remove the painted on enforcer. Other times I might even add a bit of painting to cover a larger flatter area where I know I want a larger support area. Generally though I know what areas need it just by looking at the model. Slicing it and looking at the dark blue extrusion in the preview is also a good habit to get into. Actually going through the preview EVERY time is also a good habit to get into looking for possible issues.

One other tip, is the support interface layer. I often set that to 4 layers on top and zero on bottom. Probably not needed on this model but when you are supporting a large flat area by having more layers it makes the interface layer thicker which can actually make it easier to remove in one peice, rather than it breaking up as you are removing it and you having to pick it off in bits.

Those areas you circle in black will print fine without and support. While the angle does increase to overhang height, assuming you are printing hot enough to get good layer adhesion the slight overhang perimeter will adhere and at the top of the arch it will be bridging anyway. While a couple of perimeter sections will droop ever so slightly inside there they arent long, are supported at both ends and the surface in there wont be worse and is usually better than what you get when printing on supports.

If you examine the slice preview closely in that area you will see that the support generation is probably CAUSING issues rather than helping with them.

Look closely at the dark green interface layer extrusion. Most of it is in 'mid air' and not supported by the organic supports under it. This is going to be messy and curl up. At that point its likely to be hit by the extruder.

Look closely at the dark green interface layer extrusion. Most of it is in 'mid air' and not supported by the organic supports under it. This is going to be messy and curl up. At that point its likely to be hit by the extruder.

You could cut the model down using sinking and the cut tools to isolate just one of those arches and print it just as an experiment. I think you will be surprised at what is possible.

For example just to show what good bed adhesion and an overhang is capable of.

Other general tips, this is a functional part as its a spool holder. More perimeters gives a stronger print than increasing infill.

I've attached an updated project based on yours with how I would print it. Personally Id check the arch/hole print with your specific material but using the cutting technique (also included in the zip file hopefully) before printing the entire thing. Doing just the arch is less than 15m and would be worth it.

RE: How do I prevent organic supports from failing?

Thank you so much for this invaluable information! I've always struggled with supports so this really helps and I truly appreciate your explanations and other tips and tricks (especially regarding perimeters as this sounds like something I definitely need to delve further into).

Thanks so much again - I'm truly grateful for your help! 😁🙏

RE: How do I prevent organic supports from failing?

This whole discussion had quite some educational value for me - at the very least, I do now know that supports are a much more complex topic than I thought.

RE: How do I prevent organic supports from failing?

So, what can I do to stop the model from printing on top of thin air like that. Should I do paint on supports in that area? I am having the same issue as OP