help with polyterra pla

Hi All,

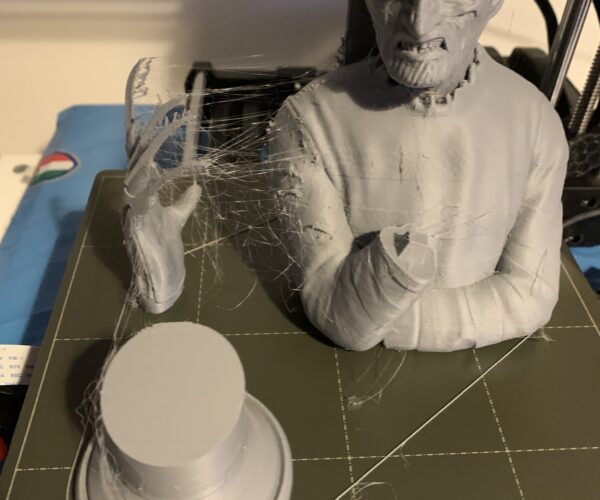

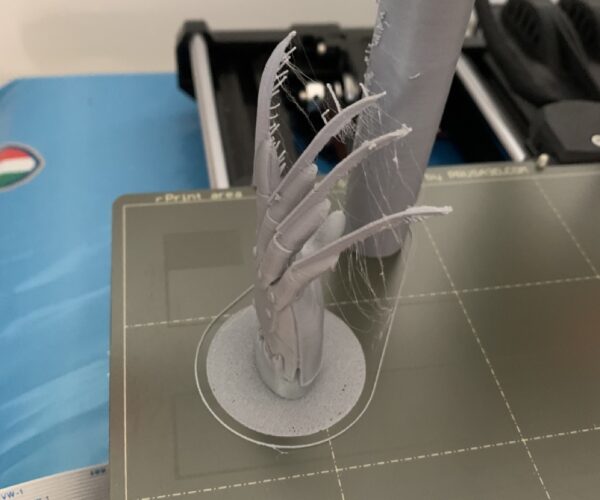

I really like the finish of this material, but I have a lot of stringing problems ... The filament is dry (I use an eibos dryer) and I started from the generic profile to which I only changed the temperatures (first layer 225, other layers 215 ... plate at 60) ... I am attaching the result of a print just completed, hoping that someone can give me some help (100% original mini)

thanx in advance

RE: help with polyterra pla

It will help if you upload your 3MF file so we can see your settings. In general, to reduce stringing, I usually have to adjust my printing temperature and restoration settings (distance and speed). You also need to slow the print down.

--------------------

Chuck H

3D Printer Review Blog

RE: help with polyterra pla

@cwbullet you are right! I can't upload the whole 3mf because the Stl is copyrighted, but I can upload my profile .ini file... hope it contains all the infos... regarding the settings, I've printed a temp tower and it seems good at 215-220, I choosed to use 215 to reduce the stringing, and I've increase a little bit the retraction distance (I've used 3,6mm) but I'm a bit afraid to increase the retraction too much for fear of clogging the extruder

thanx a lot

RE: help with polyterra pla

# generated by PrusaSlicer 2.5.0+MacOS-arm64 on 2022-10-09 at 08:13:37 UTC

bed_temperature = 60

bridge_fan_speed = 100

compatible_printers =

compatible_printers_condition = nozzle_diameter[0]!=0.8 and ! (printer_notes=~/.*PRINTER_VENDOR_PRUSA3D.*/ and printer_notes=~/.*PRINTER_MODEL_MK(2.5|3).*/ and single_extruder_multi_material)

compatible_prints =

compatible_prints_condition =

cooling = 1

disable_fan_first_layers = 1

end_filament_gcode = "; Filament-specific end gcode"

extrusion_multiplier = 1

fan_always_on = 1

fan_below_layer_time = 100

filament_colour = #FF8000

filament_cooling_final_speed = 3.4

filament_cooling_initial_speed = 2.2

filament_cooling_moves = 4

filament_cost = 25.4

filament_density = 1.24

filament_deretract_speed = nil

filament_diameter = 1.75

filament_load_time = 0

filament_loading_speed = 28

filament_loading_speed_start = 3

filament_max_volumetric_speed = 15

filament_minimal_purge_on_wipe_tower = 15

filament_notes = ""

filament_ramming_parameters = "120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6"

filament_retract_before_travel = nil

filament_retract_before_wipe = nil

filament_retract_layer_change = nil

filament_retract_length = 3.6

filament_retract_lift = nil

filament_retract_lift_above = nil

filament_retract_lift_below = nil

filament_retract_restart_extra = nil

filament_retract_speed = nil

filament_settings_id = ""

filament_soluble = 0

filament_spool_weight = 0

filament_toolchange_delay = 0

filament_type = PLA

filament_unload_time = 0

filament_unloading_speed = 90

filament_unloading_speed_start = 100

filament_vendor = Generic

filament_wipe = nil

first_layer_bed_temperature = 60

first_layer_temperature = 225

full_fan_speed_layer = 4

inherits = Generic PLA

max_fan_speed = 100

min_fan_speed = 100

min_print_speed = 15

slowdown_below_layer_time = 15

start_filament_gcode = "M900 K{if printer_notes=~/.*PRINTER_MODEL_MINI.*/ and nozzle_diameter[0]==0.6}0.12{elsif printer_notes=~/.*PRINTER_MODEL_MINI.*/ and nozzle_diameter[0]==0.8}0.06{elsif printer_notes=~/.*PRINTER_MODEL_MINI.*/}0.2{elsif nozzle_diameter[0]==0.8}0.01{elsif nozzle_diameter[0]==0.6}0.04{else}0.05{endif} ; Filament gcode LA 1.5\n{if printer_notes=~/.*PRINTER_MODEL_MINI.*/};{elsif printer_notes=~/.*PRINTER_HAS_BOWDEN.*/}M900 K200{elsif nozzle_diameter[0]==0.6}M900 K18{elsif nozzle_diameter[0]==0.8};{else}M900 K30{endif} ; Filament gcode LA 1.0"

temperature = 215

Had you not mentioned the dryer I would have said the looks like a combination of printing too hot and wet filament.

Check your print fan, is it coated with layers of gunk reducing its efficiency?

Cheerio,

RE:

Here are the settings I changed to get PolyTerra PLA to print on my mini+

- Nozzle First Layer: 210C

- Nozzle Other Layers: 205C

- Retraction Speed: 40 mm/s

- Minimum Travel After Retraction: 3mm

Other Info

- I had problems with the cardboard spool not unrolling consistently with the stock Mini spool holder.

- So far I have been unable to get PolyTerra to work with my MMU2 or Palette 3.

- Try drying the filament at 55C for 6 hours.

This should at least give some things to check. Good Luck.

RE: help with polyterra pla

Had you not mentioned the dryer I would have said the looks like a combination of printing too hot and wet filament.

Check your print fan, is it coated with layers of gunk reducing its efficiency?

Cheerio,

The fan is clear... in fact the prints without retraction look good... maybe the temperature it's too high...

Here are the settings I changed to get PolyTerra PLA to print on my mini+

- Nozzle First Layer: 210C

- Nozzle Other Layers: 205C

- Retraction Speed: 40 mm/s

- Minimum Travel After Retraction: 3mm

Other Info

- I had problems with the cardboard spool not unrolling consistently with the stock Mini spool holder.

- So far I have been unable to get PolyTerra to work with my MMU2 or Palette 3.

- Try drying the filament at 55C for 6 hours.

This should at least give some things to check. Good Luck.

i try your settings and see if anything changes ... i see you print at lower temperatures, surely this will help ... cross my fingers 🙂

thank you all

RE: help with polyterra pla

Hi @k7zpj,

This is Frank, one of the Customer Success Agents of Mosaic Manufacturing. I have noticed that you're having trouble in making the PolyTerra PLA to work with your Palette 3. We encourage our 3D Printing community users to raise any inquiries and/or concerns about our products via [email protected] between Monday to Friday 10 AM to 6 PM EST. We'll be more than glad to address these as soon as we can. Thanks!

Try drying the filament more. Perhaps you got one that has been badly treated in the warehouse.

Cheerio,

RE: help with polyterra pla

This is PLA. I rarely get stringing, but when I do, it is almost always a temperature, part cooling, or hydration issue.

--------------------

Chuck H

3D Printer Review Blog

RE: help with polyterra pla

It's strange because I've never had these problems with other pla ... The filament has been in the dryer for 3 days, the fan of the mini is clean and set to 100% ... I try to further reduce the printing temperature and see if it improves ...

RE: help with polyterra pla

That might work. I guess ti could also be bad filament.

--------------------

Chuck H

3D Printer Review Blog

RE: help with polyterra pla

PolyTerra PLA is a modified form of PLA that has been optimized to increase rate of compostability. The modifications also produces a model with a really nice matte finish. However, it prints a differently than generic PLA including a tendency to be stringy. I have observed this too with the roll that I used. So this isn't a bad roll or a really wet spool of filament.

The key is to finding the right profile settings to obtain optimal printing and then sharing the results so it is easier for the next person. Here is the link for the filament info for people following this thread: polyterra-pla-info

If dropping the temperature down doesn't fix the stringing issue then you may need to decrease the print speeds.

Try changing the following (Print/Speed):

- Max Print Speed: 70

If that doesn't help try changing (Print/Speed):

- Perimeters: 30

- Small Perimeters: 20

RE: help with polyterra pla

At the moment I managed to get a sufficient result by reducing the temperature to 195 ° C ... it's not exactly perfect, still a bit of stringing is there, but now it is much improved ... I will continue to use it and maybe refine the profile because the fact that it is compostable interests me a lot

Thanx a lot