First prints - not sticking to bed enough

Received printer 2 days ago, assembled it that same night.

Had trouble with not being able to get through the bed leveling because the left had more gap than it should. Loosened the 3 screws that hold the two major pieces together and leaned the "tower" to the left while tightening. Fixed that problem.

Now I can't get prints to stick well enough. I think I've set my Z height right - if anything I'm squishing the bead of plastic too much. I couldn't get very far into a print at all using the textured bed. It would peel off after the 3rd or 4th layer. I cleaned it with the supplied swab and it didn't help. I have not yet tried the dish soap cleaning recommended by a forum contributor. Instead, I went to the non-textured bed and adjusted my Z height for it. It prints a lot more now but still peels from the bed too soon.

I tried printing the whistle that comes on the USB stick. It did pretty good until the small vertical column that represents the top of the whistle (when blown) near a person's lips separated from the adjoining edge that was laying flat on the bed. It doesn't look like the separated piece was touching the bed, just the whistle sidewall piece on the bed. I let it continue to print for a long while and the rest of the whistle was looking good. I stopped it when the printer began to print the layers that would have fully enclosed everything. I reasoned that that part of the whistle wasn't getting a lot of support and decided to print something else that I thought would need less support. Before I mention what I chose, since none of the examples I tried have no "support", I assume almost everybody can print them w/o adding support - right?

I moved on to the boat. Again, it was doing well but at about 20% done I could see the boat would tilt upward at the bow as the printer would be laying down a bead at the stern. I crossed my fingers and hoped it would be fine until the end - nope - fully detached from bed at about 38% done. The boat looks good otherwise. The printing on the bottom is amazingly (to my newbie eyes) well defined. I'm open to suggestions on any of what I've asked so far.

The display shows the nozzle is set to 210 and the bed is set to 60. I'm using the black PLA that Prusa sends in the box for free.

Also, does anybody use the glue sticks on these Prusa bed sheets or is that for lesser quality beds?

Thanks in advance,

Rich

RE: First prints - not sticking to bed enough

You can certainly try glue sticks on the bed but I would try fine tuning the z height calibration. That is key for a solid first layer.

I would also recommend the smooth sheet over the textured sheet if you are using Prusament PLA. I had very little lucky with getting my prints to stick on the textured sheet.

RE: First prints - not sticking to bed enough

@brady5acct

I received my Mini on Monday and spent loads of time trying to get the Live Z right. Maybe I was too cautious, but it seems pretty good now. I've begun printing parts for the PPE shields working with a group in California. I'm using the smooth sheet with Prusament PLA that I got with the printer.

I had read lots about Live-Z calibration Jef Jordan's way and more at Bob Cousin's page. For a 1st timer like me I found this a much better way to get it right than the built-in wizard. If you follow this method, be sure to go all the way to page 34 of the comments and grab Joan's gcode that actually works right for the Mini. You can see my comments there as well trying to figure things out for the Mini. One comment in that long long post said to be sure the print was really sticking together as a single sheet, not a bunch of parallel lines. It took me a while to believe that, but eventually I got there. Now things stick great and the 1st layer is smooth when I take them off.

Good luck to you.

RE: First prints - not sticking to bed enough

@omari

Ok, i'll see what i can do with the Z adjustment before considering glue sticks. It's also nice to know people have found the textured sheet harder to deal with. Thanks Omari.

RE: First prints - not sticking to bed enough

@mog

Thanks for the references. I read over them quickly once. I'll read them more critically and try them out soon. It's good to know I'm not alone with trying to get this right and that it can take a fair amount of trial and error. Some of the postings I read said new owners of the Mini had good prints right out of the box and that was surprising to me and a little discouraging (and they didn't say which sheets they were using or which examples they printed). Thanks Mog

RE: First prints - not sticking to bed enough

having the same issue , i just put mine together today. Will that Gcode file work for the mini as is ? It looks like there are some commands she listed on that post, not sure if I need to modify it.

RE: First prints - not sticking to bed enough

@kevman

Using Joan's gcode worked fine for me. She sliced it for the Mini, so it uses the correct mesh leveling that Jeff's gcode did not since he made it for the mk2-3 series.

I've since updated my start gcode to center the MINDA over the center of the bed when warming up because I read about some folks having problems with variable readings from their probe on a cold morning start vs later in the day on subsequent prints. More info here

RE: First prints - not sticking to bed enough

@kevman

Using Joan's gcode worked fine for me. She sliced it for the Mini, so it uses the correct mesh leveling that Jeff's gcode did not since he made it for the mk2-3 series.

I've since updated my start gcode to center the MINDA over the center of the bed when warming up because I read about some folks having problems with variable readings from their probe on a cold morning start vs later in the day on subsequent prints. More info here

Thanks Mog. Since I am a bit new to this world , i have a question or two after walking through the other post. . The idea of that model is to print it and live adjust the z so that I can get different pattern/fill/uniformity to get a measure of what would be ideal based on the way it looks correct ? Is there a min/max threshold for the Z axis so that I dont start blind ? Thanks!

RE: First prints - not sticking to bed enough

I have the same problem. Im a newby to 3D printing. Is it a matter of adjusting the Z adjustment?

RE: First prints - not sticking to bed enough

I'm also brand new to this, since I just got my Mini last week Monday and it was my 1st ever 3d printer. So, I'm a week ahead.

Indeed the idea is that you run the square multiple times until you get it right. One key thing is that when it's right there should be NO gaps at all between the lines. When you take it off it is smooth on the bottom and no bumps on the top, although not as smooth. I did this all with the smooth sheet and PLA, which I've heard are a good combination. For PETG or TPU it sounds like some people like the textured sheet better.

As to a place to start, the distance is an offset from where your MINDA probe detects the sheet and the tip of the nozzle. Apparently those vary by printer, which is the reason they have Live-Z adjustments. Since I did the hot end adjustment, I pushed up the heatblock and nozzle and then adjusted my MINDA, so my adjustment will not be like yours. I ran the square about 14 times, because I was way high to begin with and was cautious about not wanting to scrape the sheet with the nozzle. I moved in increments of .02 all the way from .0xx to .400 ending at .365. I would change the live-Z after about 1/4 of the sheet was printed, since I thought that was enough to see what was going on. I also held them up to the desk light I had so I could see the comparative gaps. In the beginning it was more like a box connected with diagonal wires. Not good, I now understand. Letting the bed cool down to at least 40ish makes it easier to remove the sheets. Maybe room temperature would be better?

RE: First prints - not sticking to bed enough

@mog

I printed this on my Mk3, the other day.

It's printed on the textured buildplate and in PLA Filament... lots of people complain that the PLA will not stick to textured buildplates. but obviously, this stayed stuck for over 8 hours, and it's 200x200x200mm so it's close to full print  volume.

volume.

Ooooooohhhh... the picture has rotated 90 degrees, (or I am up the wall... )

And my secret Bed cleaning process.

Take your build plate to the kitchen sink, use a new sponge, dishsoap and water, scrub the build surface every which way, and Rinse well with hot water, then wash and rinse again, and finally immediately dry with clean plain paper towels.

That's it... handle it by the edges and try your next print!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First prints - not sticking to bed enough

@joantabb

Joan, I did follow your "secret" bed cleaning process. It has worked great for me so far! Thanks. N0 cleaning since the initial time either. I just try to be careful to not touch the print area when I pop things off.

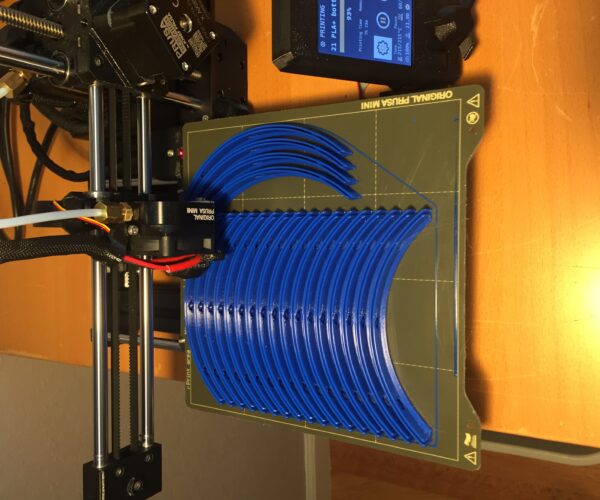

I've printed about 400 of the bottom supports for the face shields and been printing almost non-stop since I got it all leveled/calibrated. I can fit 21 of them on the build sheet at a time and it takes about 8 hours at 130% speed. There is a local group nearby that has delivered 7480 shields so far and does about 500 per day at this point. www.covidshieldnexus.org If anyone else would like to work with a pretty organized group that has lots of requests to fulfill, consider joining in...

RE: First prints - not sticking to bed enough

I just don't understand why 95% of my PLA prints on a MK3, textured bed are great. But the Mini is 5% success. Just won't stick. I've cleaned the surface 90% IPA really well as I do on the MK3. We bought 3 minis and all have the same problem. What a disappointed customer to do?

RE: First prints - not sticking to bed enough

@joantabb

Glad your cleaning process works for you Joan. The Prusa instruction say Do Not Use Water or any other cleaning supplies but IPA. Dear JP, why not thoroughly clean the beds before they leave the factory? You can see a difference from before and after an IPA washdown. Not that helps on the Mini PLA to stick.

Signed, Frustrated, Disappointed, WTH, Oh No You Didn't

RE: First prints - not sticking to bed enough

@othoap

Different Prusa Documents say different things.

https://help.prusa3d.com/en/article/first-layer-issues_1804

https://help.prusa3d.com/en/article/i3-printers-regular-maintenance_2072#rods-and-bearings

Both say you can use soap and water.

I offer suggestions that work for me,

You can make your own decisions.

Happy printing,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First prints - not sticking to bed enough

Thanks for the reply and links. Been there done that. I've print 100 parts a week, for 8 years on many different printers. I designed and built printers from the ground up. We have 5 MK3 and I got an MMU2 to work. But gitting PLA to stick to a textured mini-bed is a mystery. I even moved one of the minis to a new building with no luck. Oh well, send them back.

No response required.

RE: First prints - not sticking to bed enough

I finished my assembly of my Mk3S today and had the same problem. Reading the instructions it was soon pretty clear that it was the Z height so I did the First layer calibration. To a newcomer it is not too clear what the height should be. The diagram of the various level of 'squeeze' isn’t that helpful, its impossible to see the thin thread and determine how much it has been squeezed. I got it to work trial and error by tweaking the head downwards but how do I know if I've got it right?

What should the nozzle tip to bed spacing be so I can check it with some feeler gauges or micrometer across the extruded filament? It all seems a but hit and miss the way its described in the manual. (If it is different depending on the nozzle and material why not a table of typical values?)

BTW as a matter of interest how does the Prusa determine the height of the nozzle from the bed?

Pete

RE: First prints - not sticking to bed enough

I've actually been having a slightly different issue that I was hoping someone might have advice on. On the mini, anytime I print something that is over an inch tall or so, the bed adhesion fails towards the end of the print. I started using glue sticks, which also didn't work, and then switched to using tape, which I've been having problems with as the tape itself sometimes peels off (presumably due to heat? IDK). Does anyone have any experience with this?

RE: First prints - not sticking to bed enough

@arunm95

Try this thread. I worked out how to set up the Z the first layer to stick and now the problem is getting my prints off the bwed

Pete