First Layer problems after nozzle service

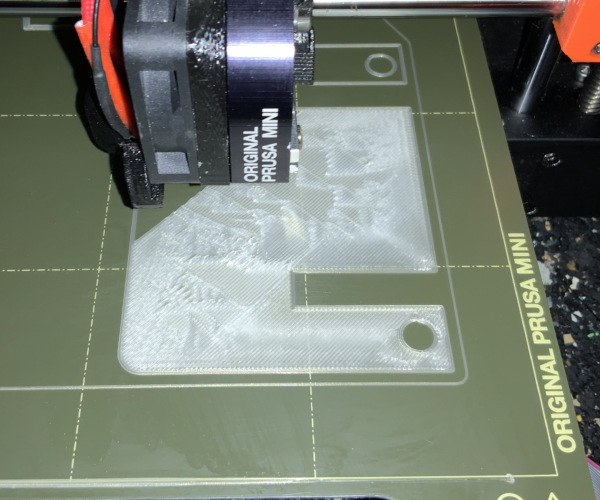

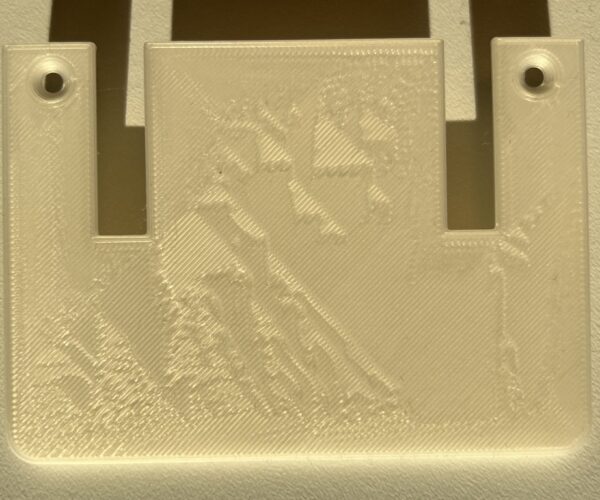

Hello, I have not used my Mini regularly and last week started printing again for a while. After some minor parts, I had a problem with the filament flow and tried to clean the nozzle. The whole thing ended in a disassembly of the nozzle, heatbreak, PTFE tube and extruder. After I got all the parts back together, the clog was gone and also the calibration of the first layer seemed good at first. Now I started some prints with very fresh PLA and compared to the pre-service prints, the first layers are pretty messy. The top layers, on the other hand, are not much of a problem and some of the prints are even cleaner. Since I still consider myself a beginner, I would be totally grateful for tips on what is the reason for these unclean layers.

RE: First Layer problems after nozzle service

It's a little hard to tell from that picture, but it looks like maybe you're a bit too low on the first layer.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE: First Layer problems after nozzle service

Once there is a clog, I replace the PTFE tube. In fact, if I grab it with pliars to get it out, it gets chucked, as it gets nicked that way. I don't reuse the hot end PTFE tubes. I just buy a bunch from Prusa and replace whenever I need to work on the hot end. That is not very often.

Regards,

Mark

RE: First Layer problems after nozzle service

I think I have an explanation and a solution. First of all, I used a new PTFE hose when assembling. The old one seemed to be tighter and the filament did not slide through it well.

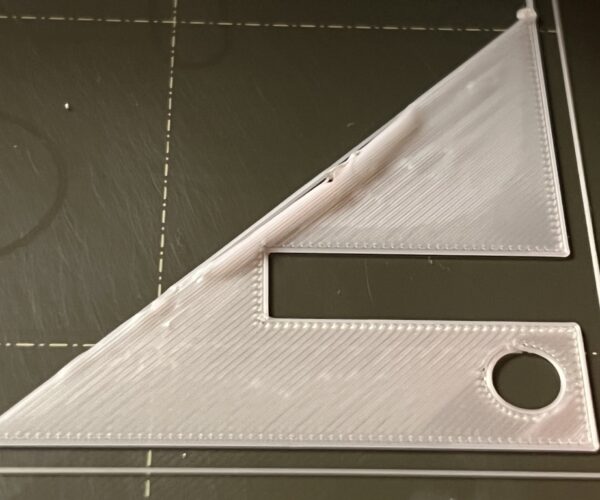

The parts I want to print right now are a card shuffler from Printables. The white parts are to be printed with a layer 1 height of 0.4 mm and from layer 2 with 0.3 mm.

I then moved the Superpinda again slightly and did a new calibration. The result looked pretty good.

However, the next prints all missed and came off the steel sheet. Cleaning with washing-up liquid, isopropanol and also changing to the previously unused steel sheet side did not bring any success at first. Then I also tried increasing the bed temperature to 65 °C again. It still didn't work.

Finally I got the idea that maybe too much filament should be applied at once and printed the parts again with the Prusa Slicer presetting 0.20 mm quality. This worked and I was able to print four parts in pretty good quality.