Extruder Failure + Blockage

So, fresh from my success in actually getting the Mini to print a Prusa logo I then went crazy and printed a full bed of chainmail in silver PLA. Perfect! Even more adventurously I followed that with a 120mm tall wall mount spool holder in Prusa Orange PETG. Flawless.

But I had to push it, didn't I. I tried to print the Rotating Rings Toy from this very site in Prusament Galaxy Black, my very first roll of it fresh from Prague yesterday by DHL.

Disaster. Print went fine until around layer 30 then small strange clicks and chirping sounds started from the extruder. I watched things for a few layers to see what was going on. The noises grew louder and I realised that the filament roll had stopped rotating. Despite all the noise from the extruder no filament was being fed and the hotend was printing air.

So I killed the print and attempted to unload filament. No joy. Tried to purge. Nothing. Unscrewed the bowden from the hotend and the extruder and found a length of filament just sitting there. (Side note: took quite some brute force to pull the PTFE tube off the filament - it seemed to be too large a diameter for the PTFE) Tried unload etc again, no luck. Released the idler screw completely and tried to extract the stuck filament just from the extruder block itself. No chance, it was jammed solid and could not be pulled out from either direction. My only option was to strip down the extruder. What I found was interesting and faintly concerning.

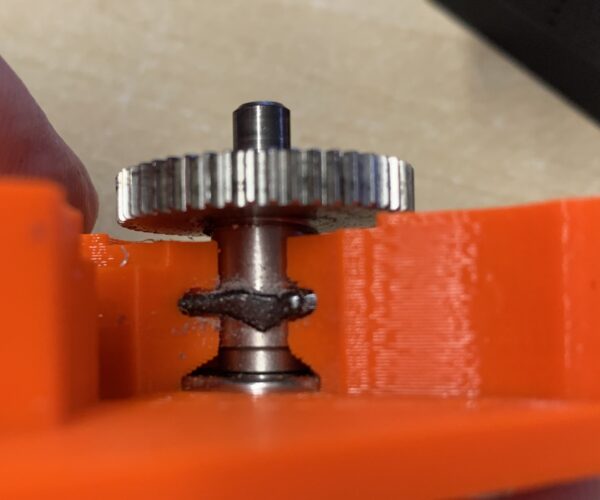

The Galaxy Black PETG had been basically crushed and ground into a blob between the gear and the idler bearing, of such a size the it could not pass either forward or back through the extruder. The only way to remove it was by cutting it to pieces with a pair of side cutters.

Once cut up and extracted this was the filament -

The small PTFE in the pic above is from inside the brass m/m adapter on the extruder housing. See the flattened filament to the left if it? No was that was going to pass through that tight PTFE, hence the complete jam.

Not too sure how to read this one yet, other than the Mini extruder does not deal with Prusament Galaxy Black PETG in any good way. Only other thing to note perhaps is the idler tension was set fairly low but was fine for the previous prints / filaments.

While I was dismantling and unclogging the Mini I printed the same model with the same filament faultlessly on a Mk3S.

RE: Extruder Failure + Blockage

This happened to me, exactly the same ......

See the post 'First Jam', by me earlier, its in this section of the forum.

After much analysis I too stripped the extruder motor to clear the grindings etc

My view of the cause was that it was the ideler gear/bearing was too loose, allowing over diameter filament to pass over the extruder gear.

I rebuilt and so far i have had no repeat (i did replace the nozzel too)

S

RE: Extruder Failure + Blockage

Ouch. Was this you or somebody else? I guess somebody else but the post looks similar. https://www.reddit.com/r/prusa3d/comments/efdgnq/im_quickly_learning_the_bowden_extruder_style_is/

RE: Extruder Failure + Blockage

@crawlerin

Not me, no. I do use both forums but completely missed that thread.

Off topic, but interesting how Josef quite often replies to Prusa threads on Reddit (apparently) but I've not seen him on here.

@steve-4

Thanks for the reply, I'll check out your post 🙂

RE: Extruder Failure + Blockage

So I killed the print and attempted to unload filament. No joy. Tried to purge. Nothing. Unscrewed the bowden from the hotend and the extruder and found a length of filament just sitting there. (Side note: took quite some brute force to pull the PTFE tube off the filament - it seemed to be too large a diameter for the PTFE) Tried unload etc again, no luck. Released the idler screw completely and tried to extract the stuck filament just from the extruder block itself. No chance, it was jammed solid and could not be pulled out from either direction. My only option was to strip down the extruder. What I found was interesting and faintly concerning.

The Galaxy Black PETG had been basically crushed and ground into a blob between the gear and the idler bearing, of such a size the it could not pass either forward or back through the extruder. The only way to remove it was by cutting it to pieces with a pair of side cutters.

Not too sure how to read this one yet, other than the Mini extruder does not deal with Prusament Galaxy Black PETG in any good way. Only other thing to note perhaps is the idler tension was set fairly low but was fine for the previous prints / filaments.

While I was dismantling and unclogging the Mini I printed the same model with the same filament faultlessly on a Mk3S

Interesting, I've spent this evening going through the same issues with a reel of 3D Solutech Black PETG. I've had to abandon a number of prints and it takes an age to remove the trapped filament. The same reel was working fine earlier with my MK3S.

I didn't have any issues with PLA prints yesterday.

RE: Extruder Failure + Blockage

So my Mini arrived yesterday. I assembled it, uploaded the latest firmware, and calibrated it. I ran the first print, which was the nut, with the Prusament sample. The print failed about 1/3 of the way through. The extruder stopped extruding. I attempted to unload with no luck. I could not manually pull the filament out while unloading. I took off the Bowden tube and it was fine. The compression fittings weren't too tight there. I pulled the brass fitting off the top of the extruder and the filament came out with it. So the PTFE tubes were just fine, but the filament was completely jammed up in the brass fitting between the Bowden and the extruder PTFE. It was as if it swelled right there. I cleared the filament from the fitting and reassembled. Second print did the exact same thing. It is almost as if the hole in the brass fitting on the extruder is too small.

RE: Extruder Failure + Blockage

What are the steps to stripping down the extruder?

The picture above is what I want to reveal. Is it just removing the four long screws on the stepper motor and gently wigging it apart? Since the MINI comes largely assembled I can't refer to the assembly document. There must be a straight path to opening it up. How's it done? I too need to clear out filament.

RE: Extruder Failure + Blockage

Hello!

Today received my Mini. Im absolutelly new in 3D printing!

Printed PRUSA logo almost fine.

Then i started to print Benchi. Looked after half hour, whats happening and find out that there was only few layers printed, printing head just moved in air, without anything coming out.

Tried to purge, unload - nothing, its impossible to get filaments out.

And i was using sample White Vanilla PLA.

Is there any solution? Do i need to open head? Is there any instructions available at the moment?

RE: Extruder Failure + Blockage

OMG, i not yet try my first print. i feel so scary because no solution for this problem.

RE: Extruder Failure + Blockage

I've only had one roll of fairly old PLA clog and gum up my extruder gear since getting my printer a few weeks ago. Otherwise, I've had pretty decent success printing PLA and PETG.

What I did that ended up helping was:

- Reseating the PTFE tube in the hotend as per the instructions here: https://manual.prusa3d.com/Guide/How+to+change+a+hotend+PTFE+tube+-+MINI/1505?lang=en#s40951

- Adjusting the height of my MINDA probe since I moved the hotend up a little bit: https://manual.prusa3d.com/Guide/Troubleshooting+the+MINI/1507?lang=en#s40940

- With no filament loaded, adjust the idler screw on the extruder to be flush with the plastic extruder enclosure: https://help.prusa3d.com/en/article/clicking-extruder-under-extrusion-and-clogging-mini_112011#there-are-3-main-things-to-check-in-case-of-the-extruder-clicking-or-under-extrusion-on-the-mini

- After loading filament into the printer, I also ended up loosening the idler screw about a quarter turn.

I did steps (1) and (2) during my initial printer assembly, and ended up doing (3) after getting my first clog after a week of printing. Bear in mind, during my first week of printing, I didn't touch the idler screw at all and went through my sample rolls of Prusament without any extrusion issues (only some adhesion issues on the textured sheet that I resolved).

RE: Extruder Failure + Blockage

So!

I did all the 3 steps. Thank you!

Unfortunately didn't helped at all.

Nozzle was full with with filament, so i heated it up with torch and cleaned with needle, that comes with printer.

Only small amount of PLA came out after that.

So i tried to manually push PLA into extruder - and i was unable to push filament throught nozzle.

AND S0 - i increased nozzle temperature till i was able to push PLA throught! AND its happening only when temperature reaches 260C.

At 270C i even dont need to push anymore, but if temp i lover than 260C - its stuck!

So i believe there should be some temperature measuring issue or something like that.

RE: Extruder Failure + Blockage

@aleksis

have you try this?

RE: Extruder Failure + Blockage

@atomleef - Hell yeah! I did all the steps before. BUT longer PTFE tube did the trick!

I realized, that spare tube is a bit longer - so i used it (before just realigned original one) and my printer is a live again! At least i did calibration and first few 3DBenchi layers looks really promising!

RE: Extruder Failure + Blockage

@aleksis

Great to hear that all problem gone, anyway can you share procedure in detail?

Thank you

RE: Extruder Failure + Blockage

@atomleef

Hey. thanks for posting this. It will save a lot of people a lot of trouble. I actually solved my issue the same day I made my post. I commented on Teaching Tech's video after he posted it. It was the exact same issue that I had. I didn't have to cut a new piece of PTFE tube, I simply loosened the grub screws and slid the heat break and heater block up until it was properly seated. Then I had to adjust the height of the probe and I was done. I hope Prusa has corrected this.

RE: Extruder Failure + Blockage

@tyson-l2

Glad to here that. 🙂 I am very newbie then i try search and real everything (I do panic with my print). But my mini not go that far because some part of circuit board have a problem(after I run wizzard) then I call the shop in my country, now they try to contact to prusa and wait how they will respond.

RE: Extruder Failure + Blockage

@atomleef

Basically i did everything @nibmaker suggested (didn't helped) + from your shared video changed hotend PTFE tube. The length of PTFE tube was a key - original is too short, but luckily for me, the spare one is a bit longer and did the trick.

And yes - i moved heater block up, as much as possible

RE: Extruder Failure + Blockage

@aleksis

Thank you 🙂

RE: Extruder Failure + Blockage

I've found PETG doesn't work well in small parts.

One solution is to check the "Only retract when crossing perimeters"

What is happening is the hobbed gear is squishing the filament by retracting and detracting a lot and the PETG is deforming, going from about 1.75mm down to a 1.5 by 2.0 oval. This gets too large for the PTFE tube and jams.

It's frustrating since that means there is a theoretical limit to layer height with retraction based upon material deformation. So filaments that can plastically deform more than others will not be able to print in high resolutions without failure.

RE: Extruder Failure + Blockage

@atomleef

... The length of PTFE tube was a key - original is too short, but luckily for me, the spare one is a bit longer and did the trick...

I noticed the same thing and found the same solution. However, I don't think the installed PTFE tube is cut shorter than it should be. I believe it was compressed too much and for long enough that it eventually retained that shorter shape.

It was quite hard to remove the original tube from the heatsink and the new one slid in without much resistance. The Knowledge Base mentions prestressing the PTFE tube by a quarter (90) turn of the lower fitting, I think at the factory they didn't pay much attention to that.

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/