reply

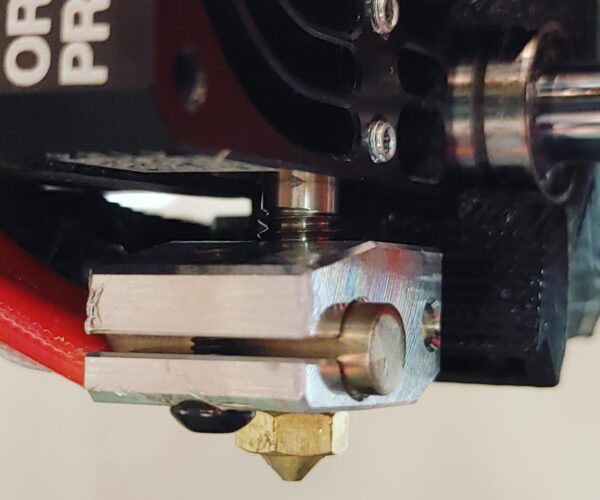

Visually, hotend is assembled as it should be. But that doesn't mean it's assembled correctly.

There are details that are extremely important. In manual, it's crucial you pay attention to Step 13, 15, 24 and 25 (including everything inbetween).

Maybe you describe here what kind of troubles you're dealing with.

[Mini+] [MK3S+BEAR]

Preassembled from prusa

Unfortunately I bought this pre-assembled directly from Prusa. =\

I've just been through so much work that I don't know what else it could be.

RE: Problems

Problems include: CONSTANT stringing (Oozing even when down to 160 Deg C while parked), intermittent under extrusion, and frequent clogs.

reply

I can understand your frustration, but trust me.. pre-assembled isn't really unfortunately 😀 .

Now, you mind to share your troubles?

[Mini+] [MK3S+BEAR]

Please bear in mind that I've only had my printer a couple-and-a-bit months, and BogdanH is far more experienced/knowledgeable than me, so this is based on my own experience: with the exception of one over-tight screw, whenever I thought there was something wrong with my pre-assembled printer, there wasn't; it was something I had done wrong/hadn't done enough/hadn't done at all.

You say prints are failing. Does your first layer go down ok? (being taught that the nozzle has to go much, much lower than I expected was a huge learning point for me). Do you have any pictures of failed prints that you can show us? And have you done a 75 x 75 square? If not, use Joan's files from here: https://forum.prusa3d.com/forum/postid/331723/

Having just been through it myself, I can really sympathise with how you must be feeling, but the people on this forum are brilliant; there aren't many problems where they conclude, "yep, your printere is broken".

Try a first layer square, and post some pics.

Problems & more

Problems include: CONSTANT stringing (Oozing even when down to 160 Deg C while parked), intermittent under extrusion in random layers (more frequent as the print continues, even when there is no clog), but also frequent clogs.

I am new to 3d printing, but I studied them to a certain extent before getting one. I have tried all the usual and I'm sure unusual fixs, 5 different brands of PLA (6 if you count the prusa sample filament), but if it's still oozing PLA at 160 Deg C while parked, I don't know what to do next. I've tried many forums and prusa live chat tech help. Four consecutive prusa tech shifts later they sent me a replacement nozzle. I already told them I had tried replacing the nozzle and it hasn't solved anything. I keep seeing a forum, video title, or a description and think "maybe it's this!", get excited, do the "fix" and nothing changes.

I'm so disappointed, and I haven't been able to do any of my usual work in the last two weeks at all because I've been spending 17+ hours each day trying to figure this out. I would much rather be able to get it work and be a nice addition to my business, but I'm strongly considering a return.

RE: First layer description and stringing pic

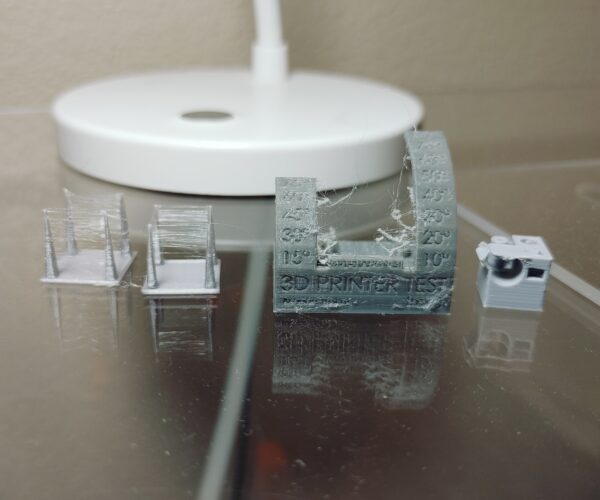

These are some tame pictures I have, but I stopped taking pictures after a while as I became more dejected. I don't have a pictures of the first layer right now (everything is put away and shut off for now because I'm so exhausted). First layer success is intermittent. It didn't start out that way. Before it would be a fairly imperfect first layer but the subsequent layers would look okay and the thing would be printed in Halloween style (stringing all over).

Sometimes the first layer still goes down okay, but what I see most frequently is under extrusion, essentially holes/gaps/missing portions around the inside of the perimeter and some parts in the middle where just no filament comes out at all so there is just a big gap. The nozzle height isn't too high because I got it too low the first night when I realized I was too high (lucky no damages). When it does work for that first layer it looks absolutely perfect, but anything after that is just not anything that can be built upon because of various degrees of partial extrusion.

This has been the case after multiple factory and prusa slicer resets as well.

The square print

I have not tried the square, I will try it tomorrow!

filament

The other thing to consider is trying a different roll of filament.

--------------------

Chuck H

3D Printer Review Blog

reply

@AndrewTerry

Being fairly new owner of 3D printer too, I don't consider myself as experienced at all. Maybe my approach was different.. I notice that many are kinda over-excited to get that "perfect print" out of the box ("it's a Prusa"). And because that usually isn't the case, frustration starts to accumulate, which again can lead to wrong conclusions on how to fix. It's like running in circle.. you know "I tried everything" thing.

Me however, I was somehow more interested on really understanding how printer works. For example.. what makes some hotend better than another, why is proper heatbreak design so important, what's the importance of extruder precision, etc. By understanding that, it's much easier to diagnose what is actually causing the trouble -and also accepting the limits of given printer. Anyway, I'm still learning 😀

@kittenspaint

Oozing... with PLA you can expect a little oozing at that temperature. Because at 160C+, PLA is already soft and there's also a little pressure inside hotend which pushes filament out. Now, how much is "a little" oozing? In park state (no extrusion), I'd say about 2-3cm long and then oozing is slowing down because of decreased pressure -I just remove that nasty thing before print starts. Now, with Prusa original heatbreak, ooze can be slightly longer (watch this for explanation).

About under-extrusion while printing... I assume you already played with that tension screw on extruder -maybe you try to find sweet spot again. Yes, I know, it seems like "no matter how much.. is always the same". But then, it's not.

Keep in mind, that in 99% cases (my guess), extrusion troubles happen either inside heatbreak (not properly assembled) or inside extruder (wrong tension setting or dirt/residue on grip gear) -by assuming that filament settings are set correctly in slicer.

Take a deep breath, open a beer.. and give it another try 😀

[Mini+] [MK3S+BEAR]

reply

I didn't see your photo at my previous post...

Stringing is mostly caused by a bit too high nozzle temperature. Keep in mind that 215C is just a suggested temperature.. try with 5-10C lower. Anyway, it's almost impossible to remove stringing entirely on such "stringing test" objects. Ok, you can maybe manage that, but then you will probably notice some other issue when printing some totally different object.

Again, there's only hotend and extruder that play the main role.

[Mini+] [MK3S+BEAR]

addition

I would add hydration or temperature.

I didn't see your photo at my previous post...

Stringing is mostly caused by a bit too high nozzle temperature. Keep in mind that 215C is just a suggested temperature.. try with 5-10C lower. Anyway, it's almost impossible to remove stringing entirely on such "stringing test" objects. Ok, you can maybe manage that, but then you will probably notice some other issue when printing some totally different object.

Again, there's only hotend and extruder that play the main role.

--------------------

Chuck H

3D Printer Review Blog

t

Oozing at 160 shouldn't happen. It may be oozing while cooling down from loading temperature to 160, but once there I don't see any observable oozing on my printers with PLA. You've tried different filaments. At this point, I would probably replace the thermistor, to see if that's the culprit. If it indicates a wrong (too low) temperature, this may lead to both oozing while parked and the excessive stringing.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/