After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

The first print was fine. But after unloading a stuck filament by taking the tube apart, this problem appeared.

I've contacted livechat. But it wasn't helpful.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

First layer after loading a filament.

And this happens after a few layers.

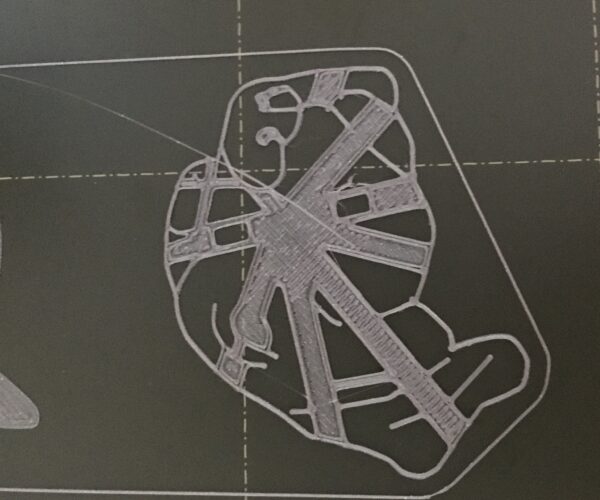

Ends up with this.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

I've found print fan isn't spinning at 230 degrees.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

I've found print fan isn't spinning at 230 degrees.

Are you printing with a PETG profile? The default profile disable fan for the first 3 layers.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

@alex-hung

I use a pla(215,60) profile to print. It jams after a first few layers.

I found print fan isn't spinning after 3 layers, so I thought it causes heat to build up to make a filament jammed in hot end with clicking noise after a few layers like one in a video below.

And this is the setting I use in slicer.

I turned off auto cooling to see if it spins printer fan. It did turn printer fan, but it jammed a filament after a few layers with clicking noise.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

I'm thinking heat creep stops extrusion in the middle of print.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

We have I2,5 and I3 as well. I2,5 simple don’t print PLA. The same problem like yours, first layers OK, then it stops. But most of our prints are ABS, and it goes great. So - PLA prints only on I3.

Heat creep - will check.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

Is the printer in an enclosure?

If so, do you print PLA with the door open?

Printing PLA in a hot environment leads to blockages,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

I think your nozzle is too close to the bed. I would suggest to try 0.02 higher in le live adjust Z.

Cheers

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

I have had the same issue with my mini+. I have thoroughly cleaned the feeder gear box but it still happens when i print at 215. What I have done that helped was to increase print temp to 225 for 0.2 layerheight and 220 for 0.1 and 0.15 mm layerheight.

That solved the issue for me. I just reckon the heatbed isnt able to heat fast enough.

Using PLA and 0.4 nozzle. Galaxy black and Purple.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

I've tried all of them mentioned and more. It still doesn't print. One of people in livechat suggested me to switch into a third party heatsink. And I hate the suggestion.

I've been trying to solve this problem over 4-5 weeks. Since I won't be able to return a printer soon, I'm getting a return label for a refund. They don't refund a shipping cost + tax which was $137 and the time. I feel horrible.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

@refunded

Have you tried the fix in this video?

I also found there was some clogged PLA between the heat sink and the PTFE tube that I removed. Now I have printed roughly 4 hours at 215C with the Gray PLA that came with the Mini and there is not a glitch yet.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

It took me weeks to get mine up to a point where I knew I could trust it on settings and understand how to react to things I see as the print occurs, this involved a detailed series of trial and error testing, documenting what I’d changed and ensuring I only altered one factor each time. A real experiment.

i found that there is no one setting to make it all better, nor one setup that worked consistently through a spool, as the spool aged its behaviour charged so its a continuous tweaking process through the spools life.

i am no expert, I’ve hunted the forums and tried bits and bobs from various posts, I’ve not taken apart the hot end, nor examined the ptfe tube for blockage or shrinkage, yet have managed to get prints to a satisfactory level to allow prints to complete, using other suggestions and the above process of controlled changes.

@refunded you mention you’ve tried all that, but without detailing actually what you’re trying and without context of how it was executed it becomes almost pointless to try and help.

here are the things I found, as mentioned though, I am no expert, but they have worked for me, remember each of these were tried in isolation to be able to see the consequences of each change.

prerequisites: get a set of test prints which are simple, reliable and focused at one purpose onto a trustworthy usb stick (I bought a brand new Sandisk usb for my configuration test prints and keep it isolated from the normal workflow).

test prints I use:

a 5 layer solid rectangle, 50*50mm. This is replicated 4 times on the print bed - this shows 1st layer z accuracy, large flat area infill consistency and overall bed location issues.

a 4 cube string test. This is from thingyverse/prusaprints - it shows how stringy a print is, I used this to dial in my retraction settings.

a calibration cube. Same locations - shows sides and surface consistency as well as dimensional accuracy - this is larger than the other tests so was a good thing to run once I thought I’d made significant progress.

With these in play I looked at temperature and speed of print, playing with prints as they emerged and tuning things and watching the results.

findings:

the bed temps were lagging about 5 degrees lower than the display = increased bed temp to 65 for pla

the z axis was different for pla and Petg, and 1st layer extrusion was often seeing the infill not hitting the perimeter = increased flow rate to 100 for the first layer and reran the first layer calibration many times to tune in the z - it was just a tiny bit lower than my original few weeks of successful prints.

the extruded clicking was noticed to appear on large flat infill areas where ever they were in a model = reduced the infill speeds to the 40mm/s, this setting immediately fixed almost all my flat layer consistency problems.

hotend temp needed to be significantly higher than stock, sitting between 220 and 230, this is not the case on petg, it only has issues on pla.

lastly, the changes to temp, z axis, infill speeds created some stringyness, following searched for forum advice I increased the retraction and this solved this problem.

do I still have issues on pla. Yes. When I hear the extruder skip, i immediately increase the temp 5degrees and massively slow down the print, these two “live” actions save 99% of all my prints.

all in all it took a spool and about 4 weeks troubleshooting to pin it to this point, coming from no knowledge to understanding the printing process.

last note, pla is not created equal, my test spools were polar opposites, grey was flawless, galaxy black was total junk and couldn’t even get one print to be successful. The tests I run, I perform on each new spool change and save a specific profile for that spool type and colour, between changes I use a cleaner spool to purge with, either it arrived in my work flow at just the point when things were aligning - or its really good, I dunno, but it’s in my process now 🙂

hope some of that can help, I understand how frustrating it can be, but there is a good printer in there.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

@ryssen2

I've done what he's done in the video twice.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

@remington

At least I've tried all of them people suggested in this post, another similar post I made and live chat.

RE: After loading a filament, it prints fine for a few layers and stops extruding properly with clicking sound.

I've packed mini. I don't try to fix the problem anymore.

Thank you for the help. It was more helpful than what's suggested in livechat.