RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@alex-hung

The only problem I have with Capricorn is that is runs a fraction smaller in OD than the PTFE tube sold or used by prusa.

--------------------

Chuck H

3D Printer Review Blog

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

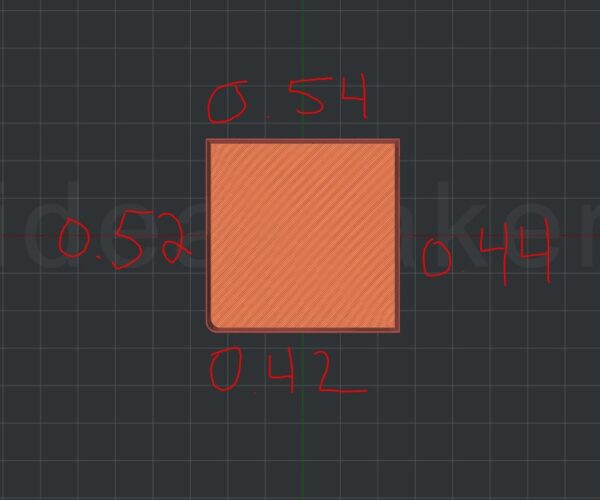

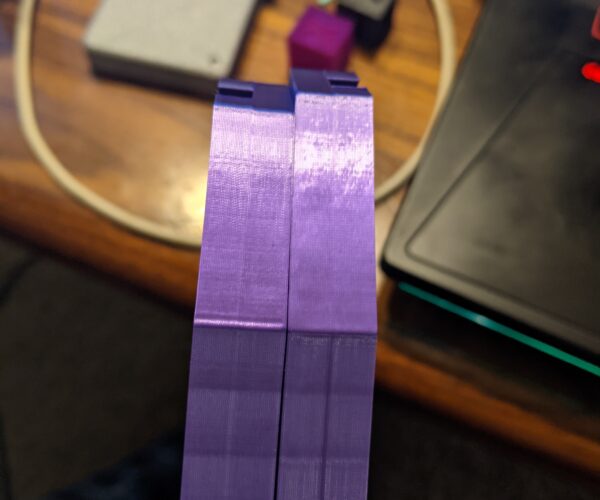

Not meaning to thread hijack, but I am having a similar issue but it is slightly different. I just have the bondtech extruder and am getting inconsistent extrusion walls (see photo below) varying from .42 - .54 mm. I just wanted to see if anyone else was having this issue as well.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Born out of staying up until 3AM, laying down for 3 hours, then getting back up to running the printer all day shenanigans.

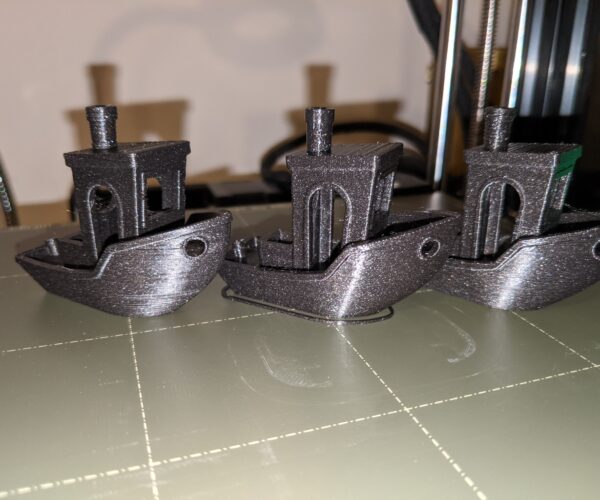

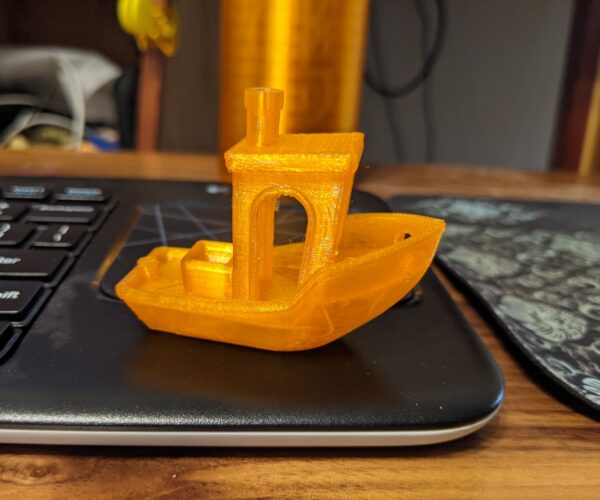

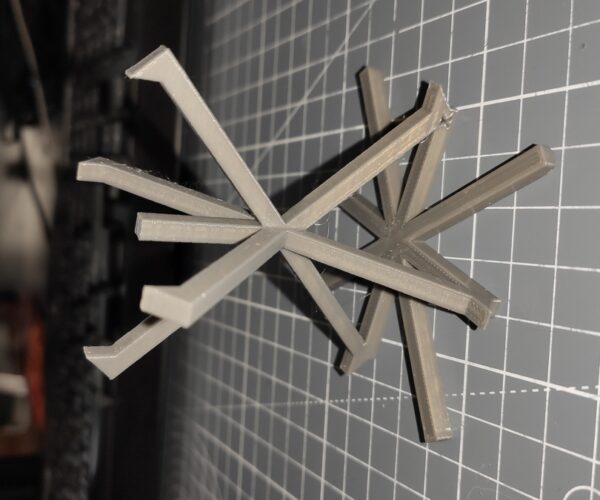

The various test subjects as they lay on my working ottoman. Each one a data point, each one a test. Given my limited material, I did major tests that tested stringing and line consistency in problem areas/retractions with the partial benchies and narrowing down the melty stacks for surface quality. Only settings that passed both got a full benchy. I was going to categorize everything in the tests I laid out in my previous post, but it got too erratic and my cats decided to play with the pieces and mix them together, so those data points are lost. The final results are as follows after almost 24 hours bouncing between the printer and my PC.

3D Benchy - Prusament Galaxy Black PLA

On the right, the benchy with only my Linear Advance change @ 215C. Looks good on broad surfaces, retraction areas and the stack where the machine slows down are not that great. On the left, the compromise, but potentially unsafe LA + 12mm retraction @ 215C. Looks averagely alright, light underextrusion near the portholes from the long retraction. Odd bow discolouration, but otherwise smooth. These two were sliced at 0.15mm layers. In the center... The final result, requiring 0.2mm layer heights, quality stock setting, LA of 0.32, and a whopping 240C at the nozzle. The entire boat is clean except one or two lines where the curve starts on the doorways. Strings are very wispy and minimal.

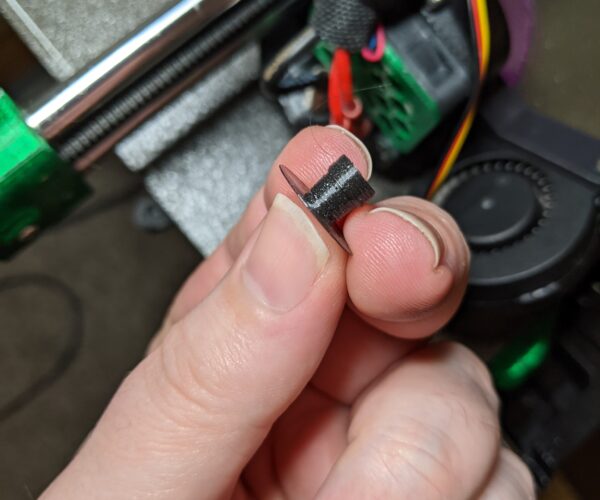

Overall, I could not get an acceptable (to me) result from anything I tried at 0.15mm. However, at 0.1mm layers, 220-225C, LA 0.32, and make sure "Retract on layer change" is enabled in filament overrides, nets you decent results. Incase you need something with details finer than 0.2mm. I did not print a full benchy at these settings (out of Prusament), but this was the resulting stack.

I am now out of Prusament, but I hope with these findings, you guys can get some decent prints without having to deal with changing out the heatbreak and/or PTFE tube so you don't have to worry about clogs. As a reminder, I've only had the issues of the random overextrusion lines with Prusament PLA, other brands of PLA, along with all my other types of filament, do not exhibit this problem. My printer only has the Bondtech heatbreak + their PID and RHD fan duct. I do not have the Bondtech extruder and I've removed the silicone sock for now. Results were managed trying to make the least changes possible for the best result, unless indicated, all settings are stock.

Some TL;DR suggestions;

For large objects without fine details: Run a Linear Advance test, or simply try 0.32 (what my printer likes). Comes out clean as seen from my calibration cube and castle from previous post. These were at 0.15mm, but should be good for 0.2 and 0.25.

For models with medium details: Use 0.2mm layer height, LA change, and 240C.

For higher details: 0.1mm layer height, LA, 220-225C, and retract on layer change enabled.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I have rebuilt my hotend with a new heater block, new bondtech heatbreak and brand new nozzle, and I still have issues. But somehow there isn't a smooth path inside it and I don't know where that is. I am very sure I don't have any sort of a gap between the nozzle and the heatbreak, so I am suspecting the bottom of the PTFE tube or the bottom of the heatbreak.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@skreelink

The linear advance results are very interesting, I never though of modifying it when I was doing my sensitivity checks.

For the rest, your results are very consistent with my experience (particularly the cat section). Retraction setting did show some small improvement in my tests, eventually I settled for the following settings:

- Retraction length = 2 mm

- Retraction speed = 40 mm/s

- Deretraction speed = 20 mm/s

Is funny that you went the other way around, to further increase retraction length. Eventually I had to go up to 245C to have good results, which is similar to your case.

I may go back to the bondtech heatbreak if the stock heatbreak fails (I enjoyed the tinkering :P), but so far the stock is holding great with the shortened PTFE tube that I had laying around and the small cut that I included in the top bearing (fingers crossed)

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@aurru

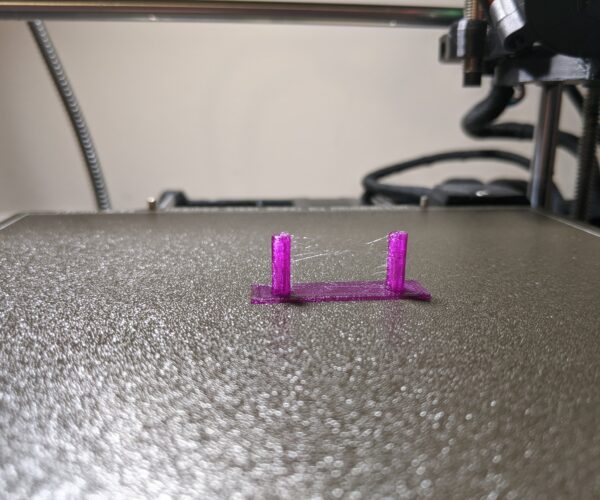

I did try the lower retractions, and they did show marginally better results, but not acceptable to me. :p For general purpose prints, those settings would likely be perfect. Admittedly, I was striving for "perfect" and went a bit to the extremes. There's more tests I want to try, but I ran out of filament. 🙁 If you swap back, feel free to continue and build on my findings! 🙃 I'm currently dialing in TPU, I've gotten grand results before, but the cherry will be destroying the strings. Results so far:

Stringing Test - Yoyi Purple TPU

3D Benchy - Yoyi Orange TPU

According to their Amazon listing, it's an 85A TPU.

YOYI 3D Printer Filament,85A TPU Filament 1.75mm,Flexible Filament, 0.8KG Spool,Dimensional Accuracy +/- 0.02 mm.

Material:It has a shore hardness of 85A.fter strict procedures, no bubbles, ultra smooth technology.Excellent bed adhesion, low- warp and low-odor, make these flexible 3D filaments easy to print.

Quality:Excellent bed adhesion, low-warp and low-odor, make these flexible 3D filaments easy to print.After strict procedures, no bubbles, ultra smooth technology,little to no odor.

Accuracy:CCD diameter measuring and self-adaptive control system in the manufacturing ensure strict tolerances.Dimensional accuracy + / - 0.02 mm without any exaggeration.

Compatible:TPU is easy to print thanks to excellent bed adhesion and the filament’s tendency to not warp Great for a variety of projects, Compatible with all FDM printers on the market which accept 1.75 mm filament.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@skreelink

You have done a terrific job with all your testning.. Across all you posts is it then possible to sum up your best settings?

Im using Bondtech extruder and heatbreak. Adjusted k-values with bondtech gcode addition but cannot get as beautyfull prints as your benchies. Good job.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@jonaslevring

The settings I used on those Galaxy Black benchy dinghies are at the bottom of the post. I can't test with the Bondtech extruder, as I don't have it, but I do have the heatbreak. I would say, run my LA test found here: https://www.prusaprinters.org/prints/53359-prusa-mini-linear-advance and whichever line looks the smoothest (mine was 0.32), put that under Filament > custom Gcode. Just remove everything there and make it "M900 Kx.xx" replacing the Xs with your results. Make sure your esteps and PID are in start gcode, pump the heat up to 240 at the nozzle, set the layer height at 0.2mm, and give it a go. Prusament is the only filament I needed to do this with, all of my other PLAs, PETG, TPU, and ASA print perfectly fine in their normal range with my K value.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@skreelink

great.. ill give it another try.. the LA-test was printed at 215, right ?

Are you using still using:

- retraction despite Marlin LA guide says close to zero (or zero) retraction?

- retract on layer change ?

- wipe while retracting ?

It seems a bit unclear to me.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Your Benchie and Column test look pretty good. I would be happy with those in TPU.

--------------------

Chuck H

3D Printer Review Blog

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I have rebuilt my hotend with a new heater block, new bondtech heatbreak and brand new nozzle, and I still have issues. But somehow there isn't a smooth path inside it and I don't know where that is. I am very sure I don't have any sort of a gap between the nozzle and the heatbreak, so I am suspecting the bottom of the PTFE tube or the bottom of the heatbreak.

Hello,

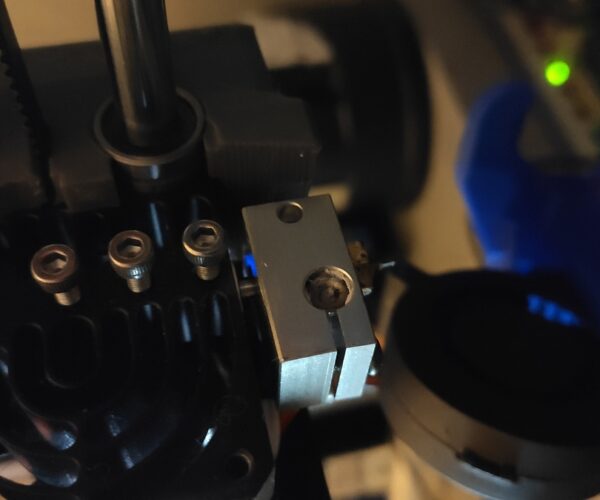

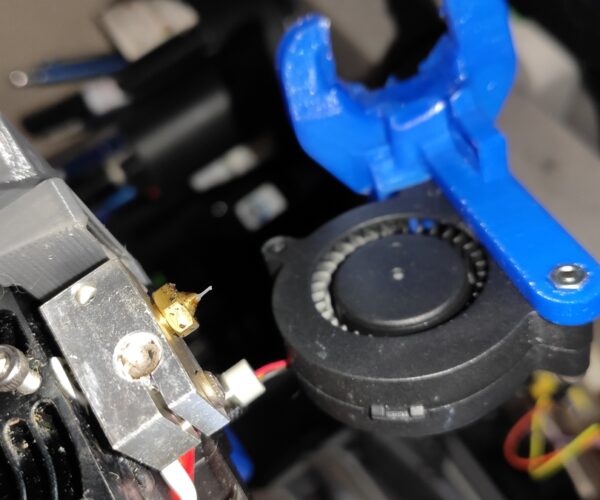

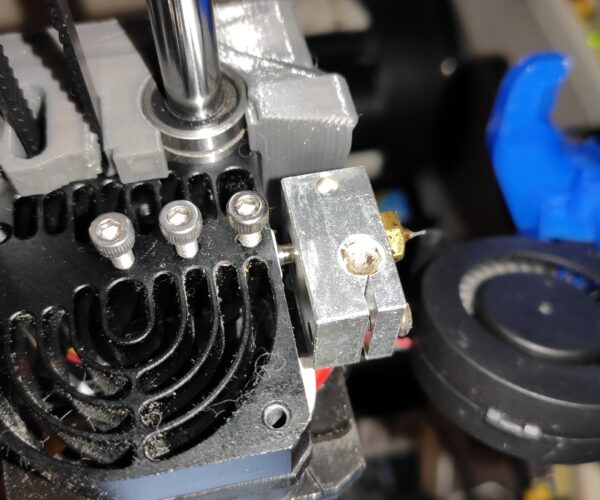

I rebuilt the hotend on my clone 3 weeks ago and it is still clean as new (3-4hrs a day printing), not shown below the silicon sock that help me on stay clean.

I use a bondtech heatbreak clone and an e3d v6 clone heatblock together with an extruder bmg clone.

I replaced the 3 small black screws by hex as (with crappy stock clone heatbreak) it happened to me that the bmg pushed down the whole hotend creating a gap between ptfe tube and heatbreak generating a lot of issues such as oozing, stringing, underextrusion, etc...

This is the gap Nozzle - heatblock

this is how heatbreak is screwed in the heatblock, the gap heatblock-heatsink is 3mm

this a skew test print with unchanged generic PETG profile, average quality PETG warhorse from Amazon, quite happy about quality.

I don't know if the original heatblock has a different thermal behavior because smaller or whatelse, I can only suggest everybody to ensure that no filament leakage occurs in both side of the heatblock, this is a good check to be sure that the hotend is properly assembled.

IMO the main problem of mini is the way heatsink-heatbreak are joined so sometimes the ptfe is short or long according on how much the heatbreak is inserted in the heatsink, this probably forced PR to avoid bmg as too strong and moving to a light extruder design prone to filament sliding than can cause underextrusion, stringing and other bowden issues. Adding this to a not properly assembled hotend (as it happened to me as noob) creates a "perfect storm" that generate a loop of issues.

Hopefully helpful to somebody

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@skreelink

great.. ill give it another try.. the LA-test was printed at 215, right ?

Are you using still using:

- retraction despite Marlin LA guide says close to zero (or zero) retraction?

- retract on layer change ?

- wipe while retracting ?

It seems a bit unclear to me.

It's an already generated gcode, I modified to work on the Mini, you just have to put it on the USB and run it. Whichever line is the cleanest, use that result.

@cwbullet

I've attached my current TPU profile to this post, unzip and put it in %appdata%/prusaslicer/filament. Remember it's built for Yoyi TPU which claims to be 85A (I'm dubious though, might actually be a 95A), but it should be a good starting point for whatever your flex is. Maybe just the temps need to be bumped to match. The following is the result of this filament profile and increasing the speed for travel to 180 (matching the default limit for non-print moves).

Stringing Test - Yoyi Purple TPU

The light fluffies still present seem to pretty much disintegrate when you touch them, so either gently pulling them off, or a bit of heat gun should destroy them. This is with 100% infill to ensure every layer ends inside the model. If you have sparse infill with small details (such as this) then layers that only do perimeters (as there's no infill on those layers) there might be more stringing and you can feel the seams. I tested printing outer perimeters first, and this solves the issue at the cost of a bit of dimensional accuracy.

Stringing Test - Yoyi Purple TPU; External perimeters first

The results of this are stunning, however. You can see a little melt near the bottom where the fan is off/low for the first few layers for adhesion. However, the upper layers look great, this was at 0 infill. My suggestion would be to choose some form of infill that guarantees at least one line of infill in the detail spots so with the 0 lift it can wipe it on the internal perimeter on moves. Or simply use a modifier in the slicer to make fine details 100% infill to make sure. Just make sure the final extrude before move is not an external perimeter. 🙃 Let me know how it goes!

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@cwbullet

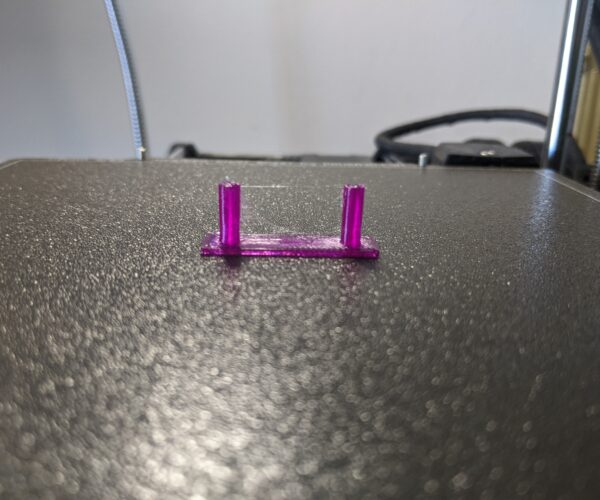

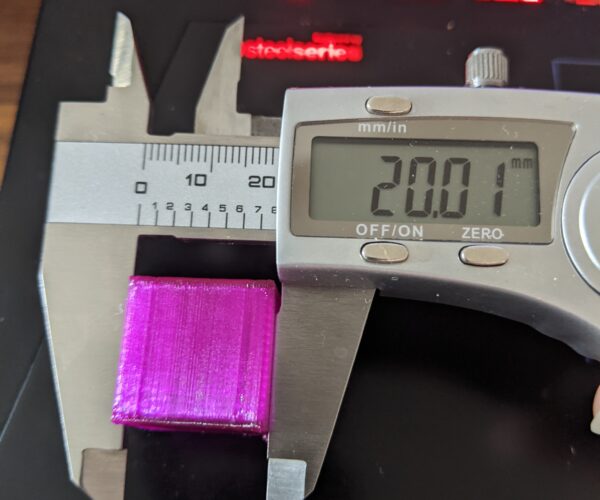

Also forgot to include some dimensional tests! Seems pretty accurate, but obviously shrinks a little as it cools. I'm going to try to bump the extrusion multiplier a little to see if it fixes it without ruining the surface finish.

Calibration Cube - Yoyi Purple TPU; X

Y

Zed

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@skreelink

Interesting that the dimensions are off. I have measured but never experienced this.

--------------------

Chuck H

3D Printer Review Blog

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@cwbullet

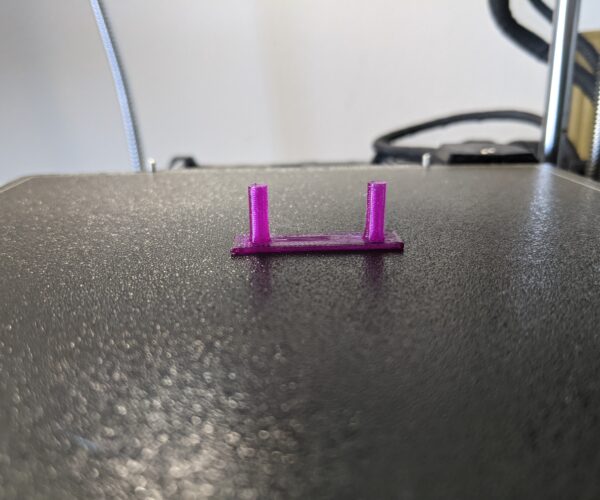

A slight bump in extrusion multiplier fixed it, my profile was 1.15, bumped it to 1.2 and this is the result.

Calibration Cube - Yoyi Purple TPU; X

Y

Zed

For a flexible material... I'll accept these results. :p

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

As an emphasis on how much this is a Prusament only problem for me... I just printed these from a cheap chinese silk filament, using the 0.25 draft preset. They're sides to what will be a yarn spooler to wind skeins of yarn onto empty filament spools. The surface is so smooth, you can see the microstepping of the drivers in the light. Especially visible on the left one. (you may have to right click > open image in new tab to see the fine steps in the full size image) The line you see in the middle is a solid topfill transition, similar to the infamous benchy line on the bow.

Yarn Spooler - CC3D Silk Purple PLA; 0.25 Draft

I wish Prusament printed this nicely for me... I want some of that Opal Green so bad...

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

This is specific to Prusament for me too, for some reason it clogs the Bondtech heatbreak, I think it's happening either at the choke point or lower. Maybe it sticks to the side of the heatbreak when it's slightly molten? And it doesn't do this for other filaments somehow.

I really want to try the stock heatbreak again but I don't have my old one and ordering a new one right now to the UK costs £16 for DHL 😱

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@robee-shepherd

It might be sticking to the throat and cooling a bit since the heatbreak does its job so well. Especially with the decreased PTFE length, it's getting closer to an all metal heatbreak vs a lined one. Try bumping your temps to 240-250 for Prusament and see if that gives you better results, maybe drop the retraction length a bit to 1.5-2mm so it's not being pulled up out of the hot zone.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I will try that, thank you!

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

update on swapping the PTFE tube for capricorn -

printer ran GREAT for about a week, printed a lot of PTFE stuff, no issues, but earlier today I started seeing very very slight underextrusion and pulled it apart and the tube has shrank a bit - but we're talking fractional mm, not a ton, but enough to cause some issues

took it apart, did a cold pull, pushed the heater block up and back in biz again