RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Ok, I finally pulled myself together and disassembled the whole hothead again... I replaced the original prusa heatbreak again (which was working flawlessly sinc reverting back) and re-assembled with the Bondtech heatbreak again using boron-nitride paste from Slice engineering.

I added the paste to the heatbreak, to the thermistor, the heater element, the threads on the heatbreak into the heater block and also to the nozzle as well. I inserted a brand new Bondtech plated copper 0.4mm nozzle for this purpose.

Also did not add the PID values what Bondtech recommends (I suppose the setting has been already compromised with the added thermal paste, so why bother...) so I was using the default settings of the Mini.

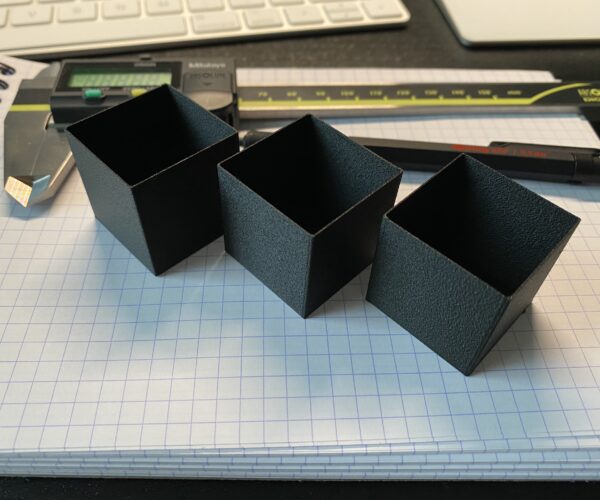

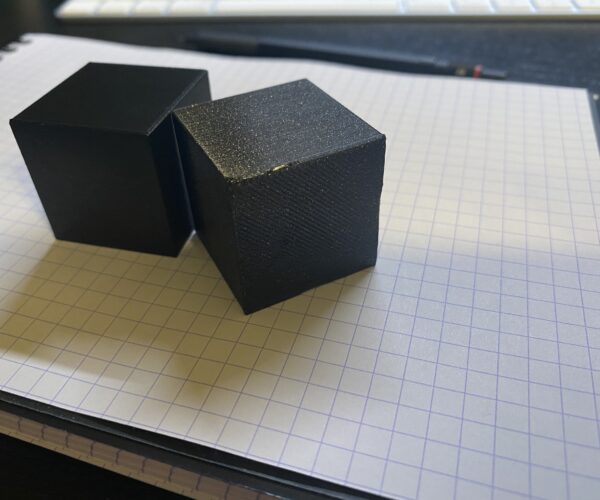

I've been printing three 30mm cubes in vase mode what used to suffer recently, but this time, they came out perfectly. Unfortunately I had to change filament also, as my Prusament Galaxy PLA has ran out. It's a basic matt black Eco PLA, so nothing fancy. Bit harder to see the layers on it, but I'm sure if there would be inconsistencies, that would be obvious.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

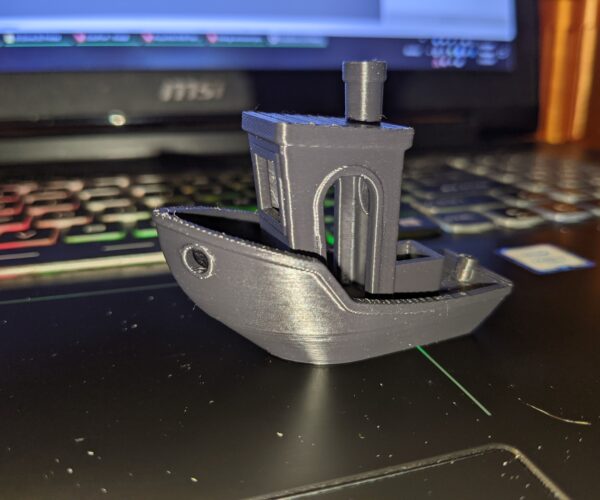

I have never had a problem with the bondtech heatbreak and vase-like prints. In my case failures came mostly from retraction heavy prints. That is why I typically use the benchy to calibrate it. It starts showing bad results and issues once it starts the cabin. For full disclosure I always had thermal paste in the heatbreak, as I have some lying around from when I assembled the computer.

In any case, just swapped it with the stock extruder and it prints flawlessly (used the benchy that came with the printer @215), with the same filament that was giving me issues before. I will be using the stock extruder from now on, if I get issues with the PTFE tube I will just insert segments on the top section as I mentioned before.

Some other prints that I did with the bondtech heatbreak:

- The same benchies. For some reasons I was only having issues with some filaments

- But I could always print vases that did not have retraction without problems

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

So if I understand right the problem that we are all facing is because of the thermal paste and if we are seeing problems again then we must use new one with the heatbreak??

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@peter-susan

Well, as it is said in my town... No need to fix what is not broken.

@adag38

As I understand the problematic is that the Bondtech heatbreak has a smaller warm zone area, so the filament may not get enough time to get warm as they extrude or with fast retractions. It seems that by apply thermal paste everywhere you may be able to mitigate it. It could be that the composition of some filaments are more tricky than others and that is why are seeing some deviations.

I think the two solutions that seem feasible right now are returning to the stock extruder and deal with the shortened PTFE tube when it happens (by either changing it with a spare, adding a section on the top as I have or modifying the PTFE tube bearings as it has been said a couple of pages ago) or apply the thermal paste in the bondtech heatbreak, nozzle and heater block to ensure a good heat transmission.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@aurru

I don't know if you followed the thread from the beginning, but initially I had issues with retract-heavy prints with the Bondtech upgrades. For a simple measure, we used the vase mode quick cube-like prints to reproduce the issue. For days/weeks I tried everything, but I did not have time to utilize the boron nitrite paste for the hotend assembly, what I did today, and the issue is gone.

It is indeed a heat-transfer issue, but more likely, the bondtech heatbreak "focuses" the heat into the hotend, and not "sucking" out any, like the prusa does, therefore less constant heat applied by the heater maybe. With the thermal paste, I suppose the whole assembly is more responsive, so the measurement and the heating is more effective. It's just a guess, but seems like, the paste on the parts solved the issue for me. Will see it on the long run, but it is very promising.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@prusatester2020

Hi,

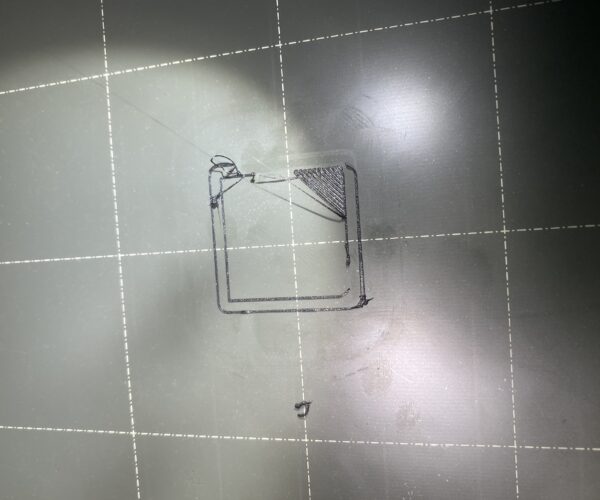

So I printed another Vader model and this time it looks worse. I then immediately printed a couple of vase cubes and the results are awful. (Please see the attached)

It doesn't look like the new thermal paste made any difference for me on the Bondtech heat break. I will replace with the original prusa mini heat break tomorrow and test.

Also did you replace the 3 individual pieces of Bowden tube with a single length of PTFE tube from extruder straight to the hot end with PC4-M8 or M10 pass through fittings? I wondered if anyone has had any issues with this single length of PTFE tube set up?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

There is one thing I'd like someone to test - setting hotend cooling fan to 100% , because for god knows why, it is set to 50% speed.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@michaelaswood

I was sure that changing the filament would not resolve the problem. Also after a few longer prints you will also have the same issue (you already have it) and I am very sorry that I was right 🙁

I think that Bondtech & similar heatbreak solutions compatible with Prusa Mini needs excellent thermal spreading and thermal paste helps. But I suspect that after some time the issue will/may appear again. I am now also suspecting that Prusa team is aware of this and that's why they continue to use their heatbreak design even with the Mini+ model.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@michaelaswood

I was sure that changing the filament would not resolve the problem. Also after a few longer prints you will also have the same issue (you already have it) and I am very sorry that I was right 🙁

I think that Bondtech & similar heatbreak solutions compatible with Prusa Mini needs excellent thermal spreading and thermal paste helps. But I suspect that after some time the issue will/may appear again. I am now also suspecting that Prusa team is aware of this and that's why they continue to use their heatbreak design even with the Mini+ model.

Hi, did you ever get a satisfactory reply from Bondtech? I have emailed their support 2 or 3 times now but I am yet to receive an acknowledgement of the support ticket or issue.

Looks like I will be installing the Mini heat break tomorrow, not that I have actually printed with it as I changed it out straight away. 🤣.

It's good to know I'm not on my own with this issue.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Previous year I received a few answers from Bondtech and they were so kind to replace my heatbreak under warranty. I also sent them my first Bondtech heatbreak for investigation. Unfortunately they said they did not have a solution for the problem and later mentioned that other customers wrote about the same problem (I think including you). I hope they will reproduce the problem and then give us a solution and/or workaround but may be more customers have to notify them for the issue.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Lemme see if I can throw a wrench into the findings. 🙃 I've been dealing with this issue myself, but ONLY with Prusament! Glad to see a thread getting some traction with the issue, since mine never really got many replies. Found here.

Info on machine:

Prusa Mini built in October

Super PINDA

Bondtech Heatbreak + Arctic Silver 5 on heatsink side ONLY (since it's rated for up to 180C, and the heatsink side should never see more than say, 100C, else it would cook the PTFE)

PID from m303 via Octoprint in slicer gcode (though I've also used the Bondtech provided PID and stock, doesn't seem to change anything)

RHD Fan duct (Pinkie Pie's V5)

Side Note: When installing the heatbreak, I did NOT remove the heater cartridge or thermistor. So whatever, if any, compound they had on them is still original. I just did it with the heat block still attached to the Mini.

Cheap filament, decent filament, it matters not... As setup, it prints quite beautifully; EXCEPT when I try to print with the roll of Prusament Galaxy Black that I bought with the printer. The inconsistency with the Prusament has lead me to mostly use PETG on the Mini (Calibration cube comes out 20x20x20.01 with PETG). Tolerance tests are all fine, even down to 0.1mm with PLA and PETG. This is what boggles the mind... I can slice using the Prusament PLA default, or generic default, and all other PLAs print perfectly fine (for what it's worth, I tried looking through the difference in settings, and the only difference seems to be Prusament is set to 215 on all layers vs only the first, someone can chime in if I'm wrong and missed something in Prusaslicer).

This lead me to think, maybe it's just a matter of temperature? Nope. All my other filaments seem to not care about what temperature I print them, they're all smooth (with only a slight variance in stringing) from 195C to 230C... Prusament? Garbage up the scale. I do note it seems to be more noticeable on smaller round areas, such as cylinders. Long walls are only moderately affected. Some examples from my other forum thread are below.

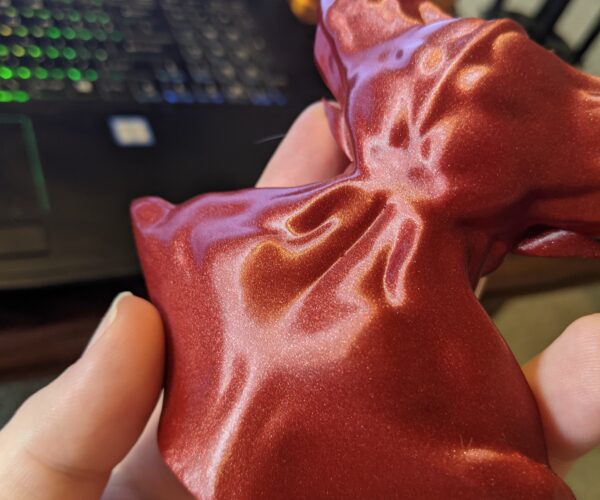

Toothless - Prusament Galaxy Black

Darkness - Eryone Galaxy Red (pictured from the back to show off just how oddly smooth it is, and feels weird too)

Test Pieces - Prusament Galaxy Black vs Eryone Galaxy Red (Same GCode using Prusament defaults)

Overall, it seems the solution for my issue has basically been to just... avoid Prusament, which is a shame (I need me some of that Opal Green). It's supposed to be the highest quality I have, but it's the only one that prints like garbage. Even drying it for ~4 hours in a food dehydrator had no change. My guess it has to be some modifier they use to change the way it flows or something vs every other PLA. I don't know if this information helps anyone or not, I'll rerun a PID tune, plug in the new numbers, and print another temp tower of Prusament and post it tomorrow with my findings.

Just to show it off, my favorite benchy. Printed with Polymaker Polylite ASA using Prusament ASA settings:

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Bah! Missed the edit window... Such a short time. Forgot to mention in the machine info section: I have an E3D silicone sock on as well.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@skreelink

When I was testing this, I used the same filament, Prusament Galaxy PLA and had the same issue. Since then I ran out of it, so I can't validate, but other filaments seems fine since.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

So the next suspect is the Prusament PLA with some unknown ingredient/characteristics that causes the mentioned issue using Bondtech heatbreak. Someone should re-check/validate the @skreelink findings ...

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I found ~1.5m of remaining Prusament Galaxy PLA in my bin, so will load it up for a last test with the cube 😀 will see

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

So the next suspect is the Prusament PLA with some unknown ingredient/characteristics that causes the mentioned issue using Bondtech heatbreak. Someone should re-check/validate the @skreelink findings ...

I dont think so - same thing happened to me when using other filaments

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I have also had trouble with Prusament Galaxy PLA. Not sure if it was before or after I mounted the Bondtech stuff.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I have had terrible adhesion issues with Galaxy Purple.

--------------------

Chuck H

3D Printer Review Blog