RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

and 2nd one

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@pinkie-pie did you use Bondtech heatbreak OR the PRUSA one because the problem we have is with the latest?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@pinkie-pie did you use Bondtech heatbreak OR the PRUSA one because the problem we have is with the latest?

Get tired with the bondtech , I use stock prusa heatbreak now.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@prusatester2020

yout tried all with no luck.

i feel with you (same effects on my prusa mini) , but all you tried did not help me too,

here someone mentioned that the voltage for the heating block was too low and caused underextrusion

(and mabe the need for higher printing temps than normal).

may you investigate this as another try to fix it?

https://www.reddit.com/r/prusa3d/comments/kqn52v/finally_found_the_under_extrusion_and_random/

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I'm sorry I did not manage to help you 🙁

I read the post and I do not think I have such a problem because I replaced the heater and the thermistor to eliminate this issue, so no thinner cables that could lower the voltage/current. Also if the voltage was lower then the thermistor will ask from the heater to increase the heat until the required amount is reached. I do not see a lot of oscillation in the temperature. It fluctuates slowly +/- 0.5-1.0 C.

I will soon order PETG if the problem is with lower temperature then it should be more clearly seen.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@mathias720

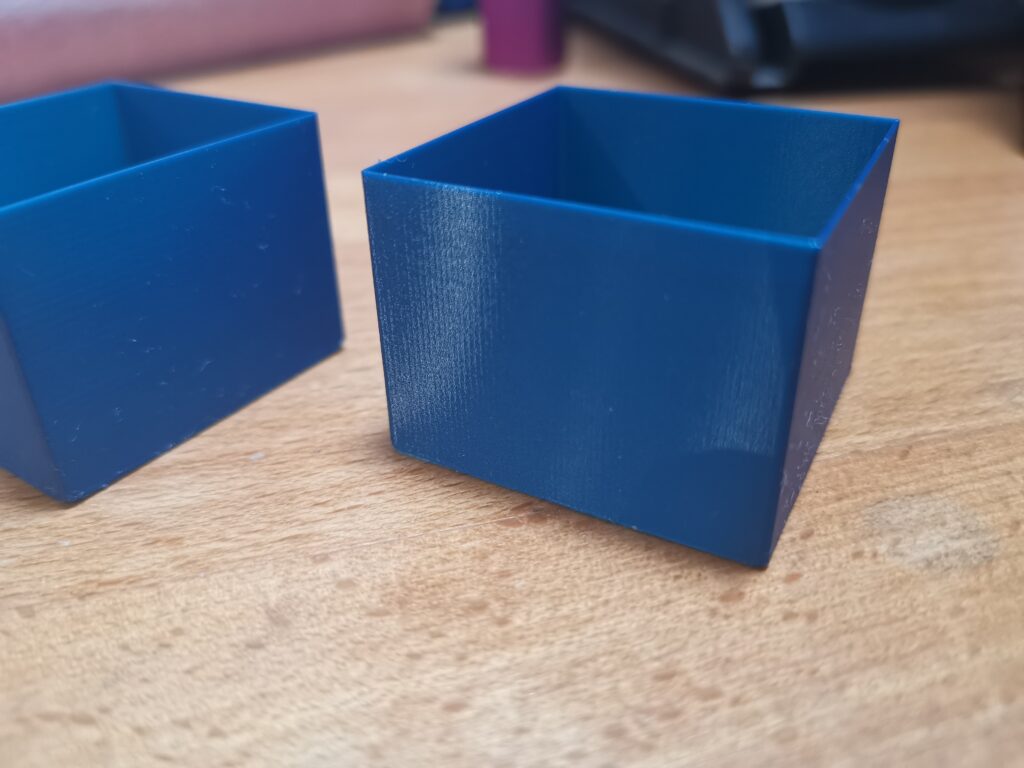

I too had been waiting on the new thermal paste, which arrived yesterday so I have reassembled the hot end and applied the new paste to heat break, heater cartridge, and thermistor as suggested, I didn't apply it to the threads on the nozzle though. I have test printing a couple of 40x40x30 vase cubes at 215/210c and they have come out perfectly. A couple of issues with the first layer sticking so raised the temperature slightly on the heat bed (63-65) and ho tend (217), but as soon as the first layer had finished all other layers were printed at 210 and the cube has come out better than any print I have done before. I don't know if this is because it's the fresh thermal paste or if the new paste has better conductivity, only time will tell I guess, but results so far seem pleasing. This is with the BondTech heat break being installed and the BondTech extruder.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@michaelaswood

What thermal paste?

Can you check the results with longer prints and retractions? Issue seems to show up when you have a lot of movement.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@pinkie-pie

This was the thermal paste I got: https://www.amazon.co.uk/dp/B078WN7PXL/ref=cm_sw_r_cp_apa_i_yM49FbX9GZD85?_encoding=UTF8&psc=1

It has the same thermal operating temperatures -30 to 300c as the AG Silver that is sold on the Prusa website but it's 1.9W/k.m whereas the AG Silver paste is 3.8W/k.m.

I printed the test sheep that comes with the Mini USB, that again was flawless.

Tonight I'm running a 6hr 30min PETG torque wrench print. It's 5 hrs into it and it's spot on so far. A small amount of stringing. This again was printed with stock temperatures and retraction settings etc. 235/85 first layer then 240/90 other layers.

If you have a good test print that you would like me to test with, please ping it across and let me know any adjusted retraction settings etc and I'll try this out for you.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@michaelaswood

Well, I had problems with this model scaled down to 20-40 %

https://www.prusaprinters.org/pl/prints/36697-darth-vader-bust-stl

Uneven layers and bad overhangs

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@pinkie-pie

Hi, I stuck this on to print a few hours ago. I shall update you once finished with the results... But so far they are doing well.

On another note, your design (pc4-m8 x 1,25 pneumatic ptfe conenctor for prusa MINI) what length PTFE tube did you use from hotend to extruder? I'm guessing you replaced the original 3 pieces that were used in the mini with just the 1 longer length?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Ah, I just replaced the nozzle, could mount the heatbreak..

So far im getting another idea how to get best of both worlds - use stock mini heatbreak without that 43mm PTFE inside, just one long PTFE from extruder to the hotend. So far it works nice, even if PTFE compresses , all you have to do is move hotend a little higher.

Another thing you can do to limit the impact of the shortened PTFE tube is to slice a small section of it and include it in the fitting at the top of the thermal cartridge. Creep usually only takes places during the early life of a structure (I am assuming is going to be the same with the PTFE tube), meaning that once the PTFE tube length stabilizes under the level of heat con compression it will probably hold its length "indefinitely".

The copper fitting itself keeps the slice of PTFE tube centered so it doesn't bother the filament and it is relatively easy to remove with a needle.

I was going to try it myself with the stock heatbreak, but accidentally broke the Y axis belt. Waiting for a replacement, will be trying this week 🙂

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@michaelaswood

Thanks for the pictures!

Yes, I use it on both ends - in my opinion it holds PTFE better than those prusa mounts, and as good as pneumatic fittings.

When metal pneumatic fitting fails, it destroys the ptfe tube , when those I printed failed - the ptfe tube just slids out, all you need is to put it on again.

So the problem...attachment shows the same model using stock 0.15mm profile , plus PID

@aurru

Oh god , why I didnt think of this! Thats genius !

I was replacing the whole hotend ptfe tubes...

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@pinkie-pie

Hi, what length of PTFE tube are you using from extruder straight through to hotend? Is it just the combination of the 3 stock lengths of Prusa Mini tubing (275+43+15) or do you allow for some extra for the brass fittings that are now missing?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@michaelaswood

I just added around 6 cm to the length of original PTFE

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@michaelaswood

As I see you already have the problem that I also have:

Would you please without changing/doing anything with the filament after such a print do the 40x40x30 calibration print in vase mode again?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@prusatester2020

Hi, I suspected that I had damp filament as this was an older filament that I hadn't used in a while (the only blackish PLA I had). I have since printed a couple more cubes with some fresh PLA and these are the results...

I will try the print again with some fresh PLA and once complete I will do the vase cube without changing the filament.

Have you continued with the Bondtech heat break or have you switched to the Prusa one?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I am using flawlessly the Prusa one. I will not change it until I have a serious issue with it.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I am using flawlessly the Prusa one. I will not change it until I have a serious issue with it.

Hi, do you have any photos (like the Vader model) of the differences between your bondtech heat break prints and now your Prusa Mini heat break prints?

Many thanks

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I am pritty sure the Mini heatbreak will print it the same WITHOUT the inconsistencies.

Here are some differences with another print from the linked thread in the first post of this thread: the left frog is printed using Bondtech heat break, the right frogs are using Mini heatbreak. Do you see the difference? :

https://forum.prusa3d.com/forum/prusaslicer/how-to-set-consistent-printed-layers/#post-284356