Subtle changes

There have been subtle change but I am not tracking any major changes to the hotend.

So , they changed something with hotend in newer minis?

As far I know, nothing was changed in Mini's hotend since launch.

--------------------

Chuck H

3D Printer Review Blog

Other possibilities

Since this thread is still active, I figured I'd post an update as i just had a failed print today.

I used FormFutura rPETG and was printing a brick like part for a router. Calibrated at 225c with a tempt tower and 90c plate. 10 hour print.

Looked really good for about 5 hours and then clicking extruder. Upped the temp to about 240c and seemed to clear, but it was too late.

Now my question is, could height have anything to do with it? Like cooler ambient higher off the plate? Or maybe the angle of the spool to the feeder is too high?

I feel like I've worked out most of the problems with my mini so far but occasionally have weird under extrusion and usually at high layers. I can't go too hot, because then I have other issues at the lower layers. Thoughts?

RE: Partial clog

I do no thing the height had anything to do with it. You developed a partial clog. Do a cold pull /Pruge and see if thta clears.

I get a few of these with rPETG

--------------------

Chuck H

3D Printer Review Blog

I used FormFutura rPETG and was printing a brick like part for a router. Calibrated at 225c with a tempt tower and 90c plate. 10 hour print.

Maybe rPETG is somehow different, but 225C for PETG seems low, it's usually at least 230C and often 240C. That might be why you had a blockage.

RE: hotend ptfe modification?

Kinda new to this 3d printing business but have three prusa mini and one dremel 3d45 and love troubleshooting so here all goes...

First prusa mini worked flawless from start and are now running with a 0,8 nozzle and petg only. The other two worked fine at first and have only had Bondtech heat-break from start. Since some time back they have severe issues as described in this thread.

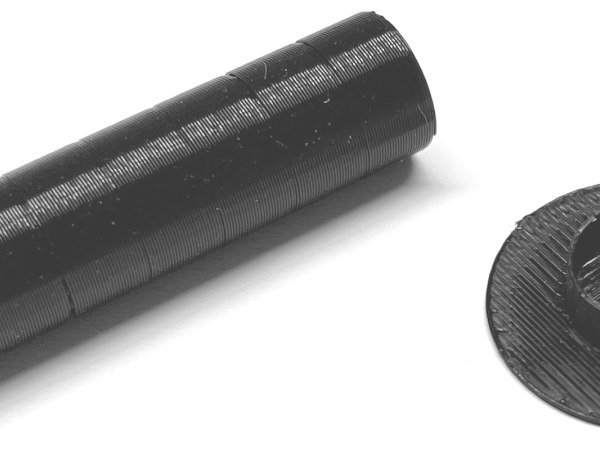

Tried it all in this thread and more - was using white prusament PLA all the time until i change to black pla prusament and orange petg prusament on the other. I could then get them to work "kinda" as the two small towers display...

This morning before work i fiddled some more and right now a print is running which i will have to get back to. But I had time to get a quick print of the tower in vase mode which never worked before (see the cubes). Accidently broke it of its base when loosening it but it starts to look promising?

All that was done for this print is standard settings in prusaslicer - vase mode - and the bondtech code for the heat-break. And a small modification to the bowden tube in the hotend...

Replaced the one that was shipped from Bondtech to a capricorn which i reamed out to 2,5mm hole and then using a 2,5mm center drill from the lathe to chamfer the inside edge aswell. If this works I will get into more details 🙂

also

I used FormFutura rPETG and was printing a brick like part for a router. Calibrated at 225c with a tempt tower and 90c plate. 10 hour print.

Maybe rPETG is somehow different, but 225C for PETG seems low, it's usually at least 230C and often 240C. That might be why you had a blockage.

Good catch. I have had a couple of clogs due to a need for higher temps.

I had a new one for me last night. My Z was too low for a particular filament.

--------------------

Chuck H

3D Printer Review Blog

titanium

Has anyone used Titanium heatbreak from trianglelab?

How it preforms in comprasion to bondtech ?

Triangle lab works

Works for me very well, I have replaced stock with bondtech heatbreak, got lot of issues... I decided to try titanium Triangle lab heatbreak and I am using it couple of months (same setting as bondtech and retraction set to 1.5mm) I am not sure if the problems were caused by retractions or bondtech heatbreak... Triangle lab titanium works flawlessly so I decided to keep using Triangle lab 🙃

RE: Triangle lab titanium hotend

I also own a Triangle lab titanium heatbreak but after my experiance with Bondtech one I did not have strength & time to test it - may be I should ?!?

.

Thats why I asked - same situation as you.

So far it seems that titanium is MUCH less prone to heatcreep than bondtech, It may really work this time.

So far it seems that titanium is MUCH less prone to heatcreep than bondtech, It may really work this time.

What is heatcreep? Joking aside, I never had problems with Bondtech. Trianglelab is one to one clone of Bondtech and being made of titanium (how much of titanium actually?) doesn't mean much, except it sounds "cool". Actually, stainless steel has better thermal conductivity.

Anyway, I hope it will work for you 🙂 .

[Mini+] [MK3S+BEAR]

Both

Both are good heatbreaks. I think there are subtle differences in heat transiontion.

So far it seems that titanium is MUCH less prone to heatcreep than bondtech, It may really work this time.

What is heatcreep? Joking aside, I never had problems with Bondtech. Trianglelab is one to one clone of Bondtech and being made of titanium (how much of titanium actually?) doesn't mean much, except it sounds "cool". Actually, stainless steel has better thermal conductivity.

Anyway, I hope it will work for you 🙂 .

--------------------

Chuck H

3D Printer Review Blog

.

Thing is, with heatbreaks - less thermal conductivity is better

True dat

Very True

Thing is, with heatbreaks - less thermal conductivity is better

--------------------

Chuck H

3D Printer Review Blog

Thing is, with heatbreaks - less thermal conductivity is better

Not really true .. heatbreak needs good cooling properties inside heatsink (that's why we use thermal paste -for better thermal transition).

In reality (as cwbullet mentioned), difference between Bondtech and TriangleLab is .. mainly price 😉 -at least that's my opinion.

[Mini+] [MK3S+BEAR]

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I'm so frustrated by this. I've spoken to Bondtech (Olof) twice about it. The weird thing is, I have no problem printing regular PLA with the heatbreak. It comes out just fine. But once I switch to silk PLA, I get the crazy underextrusion followed by blobs. I just spent a few hours printing, tweaking settings, printing, with no real improvement. I changed extrusion multiplier, retraction length, retraction/deretraction speed, temperature. I can't imagine anything else to mess with.

I really wanted it to work, because I am tired of continually feeding the stock heatbreak a constant supply of new PTFE tubes... Oh well. Back to stock for now I guess.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

use capricorn ptfe - it last much longer , on mine it was around half a year or so.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Thanks, I just ordered some and will swap it the next time it starts acting up. Hopefully I get another chance to play with the bondtech heatbreak and figure it out.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I had the same problem. Only thing that worked was increase the temperature to 230 and increase printspeed and minimal printspeed (in cooling) to 60 mm/s. This filament has a heatcreep problem, when it get to soft it starts to clog.