RE: Seltsames Extrusionsproblem mit Bondtech-Extruder und Wärmepause bei Prusa Mini

With Prusament... I've tried the settings from @daniel and @skreelink and they don't work at all for me. 🙁 I actually stopped the Benchys before they even finished the archways.

The only thing that seems to really make a big difference is increasing the temperature for Prusament to 230C, which feels way too hot for PLA. Every other brand of PLA is just fine with Generic PLA settings (or AmazonBasics PLA).

Generally, every Benchy is fine until it gets to around the porthole, and then depending on settings (this is where it retracts a lot I think) it can be absolutely terrible all of a sudden.

I bumped the temps all the way up to 250 degrees and got a nice benchy, I wouldn't worry too much about 230C. Silk PLAs tend to do well in this range (I normally run 220-225 for silk PLA) and since Prusament already requests higher temps at 215 default, 230 should be about right since the bondtech heatbreak creates a shorter melt zone by having a proper hot/cold zone cutoff instead of allowing heat to travel up the heat break to pre-soften the PLA. The same effect of slower or lower retractions is what I figure, keeps the end in the hot zone longer, which is why higher retraction areas, or fast moving areas (where it's just pumping it quickly) seem problematic. Whereas the higher temps lets it simply melt faster to compensate. The way it's Prusament PLA only is still a strange stickler to me... Try a mix; reduce retractions to say 2.5mm, speed to 40, and temps at 220-225 and see how that works out.

I recently installed a Dragon hotend on my MINI. My current settings have stayed the same as I had before with BondTech Heatbreak. I think that it works for me with the small retraction, is due to the Steinbock XS series PTFE, I also read somewhere that you should reduce the retraction by half and then gradually increase it, for me it was 1,4mm. And to come to the Prusament filament, I once got a roll of Prusament PLA Galaxy Black as a gift from Prusa and had some problems with it, even on Prusa MK3S, especially there, where many Move-ins taken place. Again, a higher temperature helped, I think about 10 ° higher than the standard which is weird given it as 215 ° but doesn't seem to work with this filament.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Thank you @skreelink! I have printed sooo many benchies, maybe half a role of Prusament's worth, and finally I have found my ideal settings. 😅

Retraction Length 1.4mm

Lift Z 0.2

Retraction Speed 60

Deretraction Speed 40

Retract on Layer Change On

Min Print Speed 25

Temp 230

Linear Advance 0.36 (set in custom Gcode)

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@robee-shepherd

Woo! Glad you found settings that work for you. That's a pretty nice looking benchy, Prusament Lipstick Red?

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Yes! It's been the most difficult of all the Prusaments for me (Pineapple Yellow is maybe the second most troublesome) so I got a little obsessed with it. With a higher temperature a lot of your and @daniel's settings got me close, but the archway kept having horrible over extrusion or melting or something.

It was Min Print Speed 25 which fixed that after trying to lower it made everything worse including the chimney, I guess the hot nozzle was spending too much time there and with a hotter temperature it wasn't cooling.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@robee-shepherd

Are you using the stock cooling or a sock? I've been using the shroud found here: https://www.prusaprinters.org/prints/52553-prusa-mini-rhd-front-fan-duct printed out of Polymaker ASA for awhile with great results. This shroud plus a sock has really decreased overheating artifacts on my prints. I recently got an MK3S+ and I daresay my Mini prints better than it does, just not as large. 🙃 I thought about getting either Lipstick Red or Pineapple Yellow on my last order, but I settled on Azure Blue and Opal Green... Omg the Opal Green is so pretty. At some point, I do need red and yellow.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I just use a sock.

I tried that shroud but I just didn't like having another fan or moving the existing fan to the front. But I had an idea for my own shroud that might work ok and would fit the existing fan outlet.

I have Azure Blue, it's lovely isn't it! I don't have the green though. I can't say I print much with either the red or the yellow.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@robee-shepherd

I had the same issues as the former posters since using bondtech heatbreak (and extruder) on my mini, but with the help of this thread my benchy prints look now rather decent.

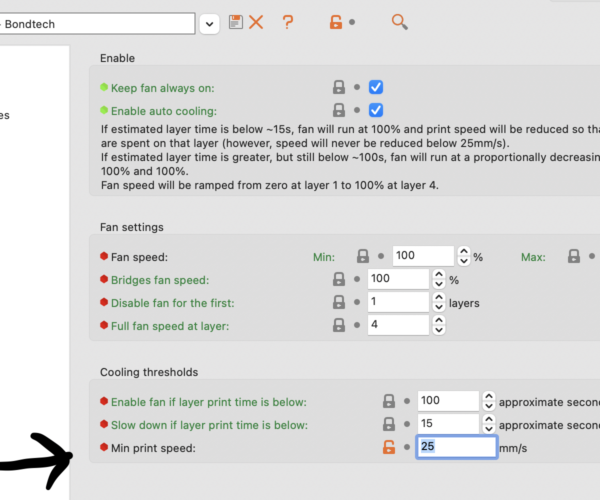

For further optimization I wanted to adjust the "Min Print Speed", but I could not find where to set it in PrusaSlicer (I am using the German version, so maybe it is translated differently). Where (in which tab and section) I can find that parameter (maybe you can post a screenshot) ?

Similiar question to LA: Do you refer to the K value in the conditional GCODE of the filament setting ? For Prusament PLA and 0.4 mm Nozzle the default setting is 0,05, so your value (0,36) seems to be really high. Or there another command / parameter ?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@robee-shepherd

For further optimization I wanted to adjust the "Min Print Speed", but I could not find where to set it in PrusaSlicer (I am using the German version, so maybe it is translated differently). Where (in which tab and section) I can find that parameter (maybe you can post a screenshot) ?

Maybe it is translated differently, here is where it sits...

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@robee-shepherd

I had the same issues as the former posters since using bondtech heatbreak (and extruder) on my mini, but with the help of this thread my benchy prints look now rather decent.

For further optimization I wanted to adjust the "Min Print Speed", but I could not find where to set it in PrusaSlicer (I am using the German version, so maybe it is translated differently). Where (in which tab and section) I can find that parameter (maybe you can post a screenshot) ?

Similiar question to LA: Do you refer to the K value in the conditional GCODE of the filament setting ? For Prusament PLA and 0.4 mm Nozzle the default setting is 0,05, so your value (0,36) seems to be really high. Or there another command / parameter ?

Min print speed is found in the Filament tab under the Cooling section near the bottom as @robee-shepherd kindly gave a screenshot. As far as the LA values go, in prusaslicer for Prusament PLA for me it has the following;

M900 K{if printer_notes=~/.*PRINTER_MODEL_MINI.*/ and nozzle_diameter[0]==0.6}0.12{elsif printer_notes=~/.*PRINTER_MODEL_MINI.*/ and nozzle_diameter[0]==0.8}0.06{elsif printer_notes=~/.*PRINTER_MODEL_MINI.*/}0.2{elsif nozzle_diameter[0]==0.8}0.01{elsif nozzle_diameter[0]==0.6}0.04{else}0.05{endif} ; Filament gcode LA 1.5

{if printer_notes=~/.*PRINTER_MODEL_MINI.*/};{elsif printer_notes=~/.*PRINTER_HAS_BOWDEN.*/}M900 K200{elsif nozzle_diameter[0]==0.6}M900 K18{elsif nozzle_diameter[0]==0.8};{else}M900 K30{endif} ; Filament gcode LA 1.0

Which has a bit of redundancy, but the LA 1.0 can also be ignored. It can be a bit confusing to read, but it checks the printer notes to see if it's a Mini, then uses elsif to pick an LA value. Nozzle sizes 0.6 = 0.12, 0.8 = 0.06, otherwise = 0.2 (0.4 fits in the 'otherwise' category). Then it elsif checks if it doesn't find the model (for other printers that support LA 1.5), it sets 0.8 = 0.01, 0.6 = 0.04, and otherwise = 0.05 (again 0.4 fits here, and the only place I can see where you got the 0.05 from). Then it gives K values for LA version 1.0, it's mostly just a catch-all line since it's for "Prusament PLA" and not printer specific like the ones that are named "@ MINI" such as Prusament PETG @ MINI is specific to the Mini, so it's code is as follows:

M900 K{if nozzle_diameter[0]==0.6}0.12{elsif nozzle_diameter[0]==0.8}0.06{else}0.2{endif} ; Filament gcode

Since it can only be selected by having the Mini as your printer, it can cut down a lot of the if, else, elsif, etc statements. It literally just reads the nozzles and sets the LA, same as I listed above. So in the stock configuration with a 0.4mm nozzle, it sets the LA as M900 K0.2, if you change thermal properties/esteps/etc the flowrate will change, that's why I made an LA test for the mini here: https://www.prusaprinters.org/prints/53359-prusa-mini-linear-advance

Just run that with PLA and whichever line is most even, use that. My value was 0.32.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@robee-shepherd

Great, thanks ! (I was wrongly looking in the "speeds" section, now I know better 😊 )

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@skreelink

Thanks for the feedback ! As newbie > 55 I am not so familiar with the conditional GCODE commands and levels 🙄 .

By the way, where can I find a description of the M-commands (I assume they are Prusa specific) ?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@robee-shepherd

Not a bad benchie.

--------------------

Chuck H

3D Printer Review Blog

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@skreelink

Thanks for the feedback ! As newbie > 55 I am not so familiar with the conditional GCODE commands and levels 🙄 .

By the way, where can I find a description of the M-commands (I assume they are Prusa specific) ?

Most of them are vanilla Marlin. Prusa specific ones can be found here:

https://help.prusa3d.com/en/article/prusa-specific-g-codes_112173

The rest of the marlin M/G codes can be found here:

https://marlinfw.org/meta/gcode/

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Damn i found this Thread too late. I already ordered one a Bondtech Heatbreak.

Now what i can do with it ? Can i put them into another printer ?

Or i just send it back and loose 4€

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@ahrimaan for what it's worth, I just installed the bondtech heatbreak last weekend and it has been working fantastic since—entirely solved my previous issues w/ clogging due to an ever-shortening PTFE tube. So I wouldn't send it back without giving it a try.

I suspect this thread is evidence of some other issue that is exacerbated by the bondtech heatbreak. Don't let it overly influence your priors on what % of overall bondtech heatbreak users experience the issue though.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I found the heatbreak was wonderful and fixed a lot of my issues. I only had other issues when I then got the extruder too, but I have resolved those now too with slicer settings. So don't worry!

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I too had a problem with my i3 that would print well for a few minutes then started blocking and the extruder world start clicking. I tried replacing everything and changing all sorts of settings to no avail. Then I put the filament in the oven at 40 degrees for 4 hours. Problem solved. It seemed that water content in the filament would start producing steam inside the heatbreak after just a few minutes of printing. This would change the characteristics of the molten filament and block the hotend leading to the extruder clicking. It worked for me.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Sorry to beat a dead horse, but this thread saved me hours of frustration. I've processed most of what's goin on here and I'm happy to say that for me, it was mostly a matter of temperature. Here's my setup.

- Mini+ plus some squash ball feet

- Bondtech dual-drive extruder

- Bondtech heat break

- PID and E steps as start code from the install manual

I upgraded after the stock heat break squished up my Bowden bit and jammed up. This is totally a thing and seems to be acute with PLA. First few prints with Prusament Blue PLA and stock slicer settings were practically flawless (including benchy) then it went from bad to worse.

After the upgrade, using the same spool, it was hit or miss. It was driving me crazy and even clicking and jamming up. I did all the ritualistic cleaning and mucked around with the Bowden, then I read this thread and it hit me. The analysis here, seems spot on, with the heat creep, warm up, retraction and temperature settings all being culprit for PLA. But the smoking gun imho was the FLIR cam showing the nozzle temp. It's barely hot enough to melt good PLA and no doubt the Bondtech heat break just exacerbates the issue by creating a decisive break without a lengthy warmup zone.

Just before I read this, I switched to Form Futura purple PLA, which is also excellent quality and I had the same issues and results. Importantly, it's also suggested to print at 210C minimum. So after I read this, I simply bumped the Slicer setting to 220C and voila, excellent, consistent prints 5/5 times thus far.

Of course its a bit more complicated if you add more variables like a sock, etc. But shout it from the rooftops. 220C seems to be the minimum with the Bondtech heat break and PLA.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Can someone make summary of what settings works?

Anyone tried increasing heatsink cooling fan PWM ? I heard it's capped at 50% speed in stock firmware.

So far I see three proposed retraction settings:

Bondtech :Increase temperature: 225-230 degrees. Retraction / De-retraction speed speed: 35-40 mm/s. Retraction distance 2-2.5mm.

Another from this topic: 1.4mm 60mm/s retr , 40mm/s detr.

also 2.5mm and just setting detraction to 20mm/s

Yesterday I gave that heatbreak another chance. Coated it in thermal silver paste when inserting, and I tried to push it as deep as possible inside heatsink to increase contact surface.

Filament im using is White PLA Impact - so far I don't see any big issues with it (im using stock retraction profile with 20mm/s detraction and Linear Advance (0.40)

Im gonna post photos when print finishes , Ill be using 0.15mm layer.

by the way - how many of you tried printing with 0.1 or lower layers ? Do the problem prevails? From my understanding, it is much less noticeable on higher layer sized (0.2 and above)

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Thanks all for the valuable information in this thread. I recently upgraded to the Bondtech extruder and Bondtech heatbreak on my Mini+. I'm using the additional Gcodes as supplied by Bondtech and added these in the Prusa slicer.

However I was having issues to print a nice 3DBenchy as more people experienced. I tried a lot and in the end used Robee's settings.

Retraction Length 1.4mm

Lift Z 0.2

Retraction Speed 60

Deretraction Speed 40

Retract on Layer Change On

Min Print Speed 25

Temp 230 (Prusament Gentleman's Grey but also Prusament Vanilla White)

Linear Advance 0.36 (set in custom Gcode) indeed also for me 0.36 seemed to be the best value.

Result for Prusament Gentleman's Grey are shown in the attached picture. Overall Benchy looks smooth but once it starts printing the door styles after the bow is finished you see strange effects as if the filament is too hot since it concentrates on these smaller areas. Same happens with other Prusament colors like the Vanilla white. The same spots show same effect on my Benchies.

Anybody have suggestions how to improve? I'm also puzzled as to why Robee does not seem to have this issue. I'm not using a sock in my heatbreak, could that be the difference?