RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@aurru

Changing back to stock heat break on all 3 of my mini's has solved my problems with inconsistent extrusions.

with bondtech heat break it would really struggle to print anything below 0.2 layer heights, especially if the area was small and lots of retractions.

I also use the bondtech extruder but have set the estep higher at 430.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

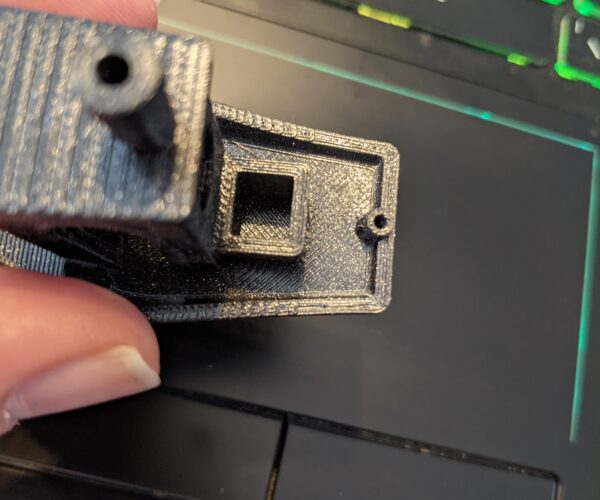

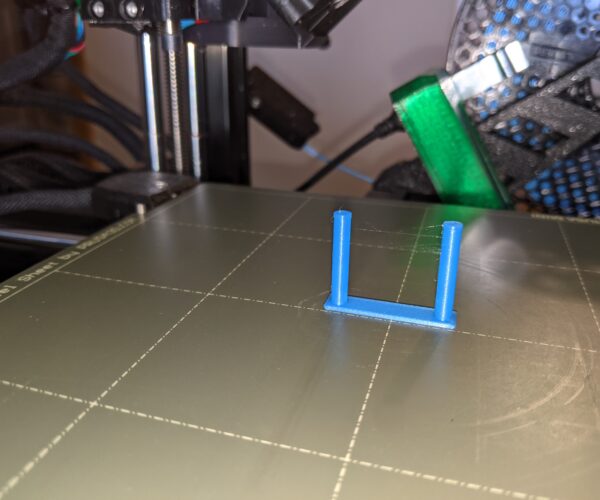

Before and after shots, after reverting back to original heat break,

Didn’t change any other settings

Prusament galaxy black

and fiberlogy easy pla black

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Before and after shots, after reverting back to original heat break,

Didn’t change any other settings

Prusament galaxy black

and fiberlogy easy pla black

Looks good.. So this was stock heatbreak and bondtech extruder ?

If so, you are using stock settings, but bondtech suggested gcode for extruder ?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@jonaslevring

Yes I reverted back to stock heat break and running the bondtech extruder.

stock settings apart from the esteps set at 430 via start gcode.

the suggest bondtech esteps of 415 were not extruding the right length.

temperature is set to 220 but that’s because I’m using e3d nozzle x

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I would love to revert back to the stock heatbreak, but I don't have the original anymore (it was stuck in a broken block :() and I also don't want to pay £16.55 to ship a tiny part to the UK (stupid Brexit!) 😞

I changed my nozzle back to a brass one from the hardened steel I had been using, which has helped a bit.

I also changed my extruder settings after measuring them, but lower to 409. I think you will just have to measure it yourself if you want to change those.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@jonaslevring

I reverted back to stock heat break and running the bondtech extruder.

I did the same, and dont regret it. It prints so much better now. Still using the Bondtech extruder, to avoid the grinding fra the stock extruder, but stock heatbreak.

Standard PLA profile, except from only 200C, and esteps to 412. Plan to calibrate K-steps one of the coming days to get rid the the last stringing.. But its right now very little. Even with white filament.

Cube calibration are very spot on with high consistency.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Been a couple of weeks since i went back to the original heatbreak on all 3 of my mini's (still running bondtech extruder on all 3). They have been working perfectly. No More weird extrusions or under extrusions.

I really think bondtech should address these issues with their heatbreak.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Some folks have issues with the stock heartbreak and some have issues with the Bondtech. Interesting to follow the discussions.

--------------------

Chuck H

3D Printer Review Blog

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Been a couple of weeks since i went back to the original heatbreak on all 3 of my mini's (still running bondtech extruder on all 3). They have been working perfectly. No More weird extrusions or under extrusions.

I really think bondtech should address these issues with their heatbreak.

I also have flowless experience since switched back to the original heatbreak while still using Bondtech extruder. This is the reason I started this thread - to address the issue to Bondtech using multiple user experience.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

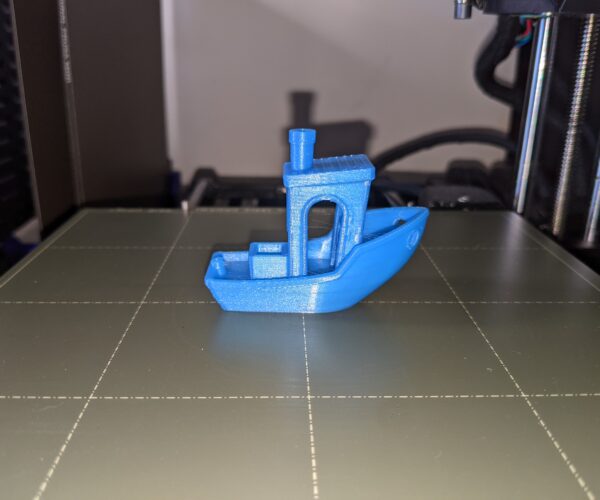

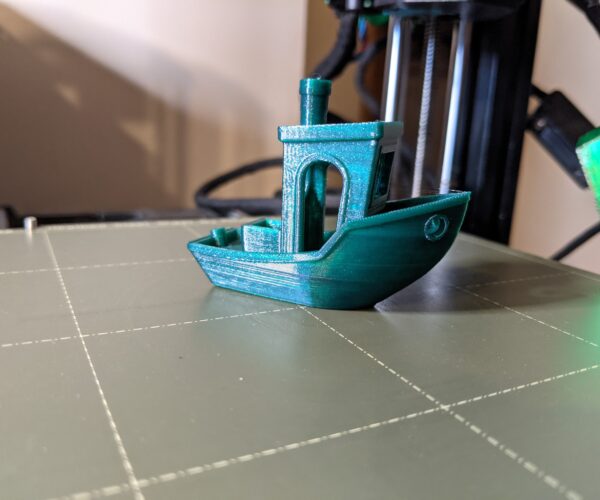

I have an additional data point to add. The issue is not Prusament specific, it's Prusament PLA specific. I just printed this perfect benchy (minus a couple wispy strings) from Prusament PETG on my Mini with the bondtech heatbreak. This was sliced with stock 0.15mm Quality Prusament PETG on the Mini with Bondtech heatbreak, Sock, and Bondtech PID.

3D Benchy - Prusament Galaxy Black PETG

Just look at that decking top layer.

Also the name 3D Benchy tag on the back of the boat is fully readable (minus horrible lighting, sorry)

These results give me a few ideas I want to test, and I happened to have acquired some Prusament Azure Blue PLA, so I'll be coming back with the results of more tests. Maybe I can find a simple compromise for those who don't want to give up the Bondtech benefits, and still want to print Prusament PLA. Something a bit better than my previous findings. 🙃

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

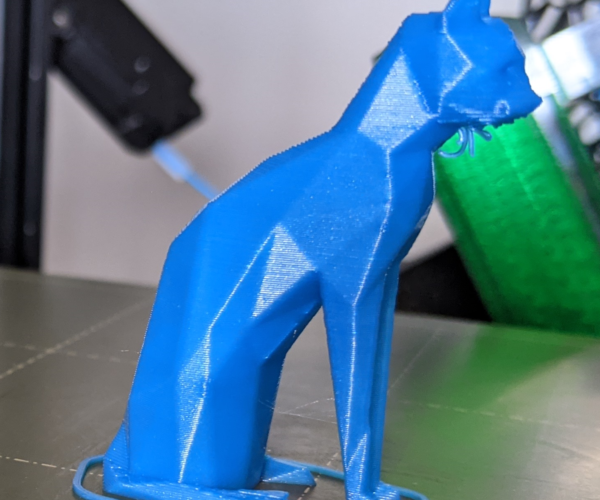

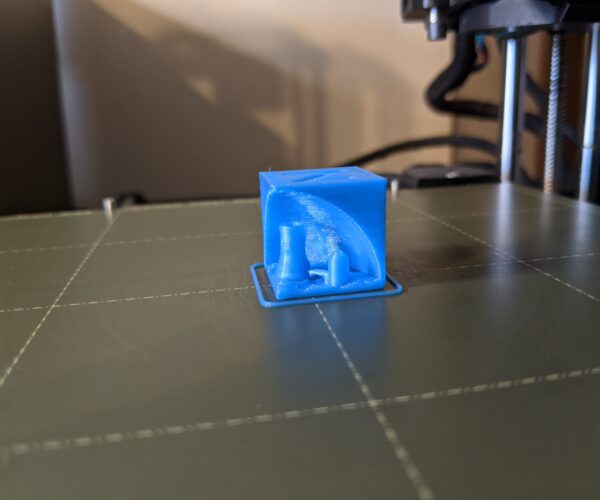

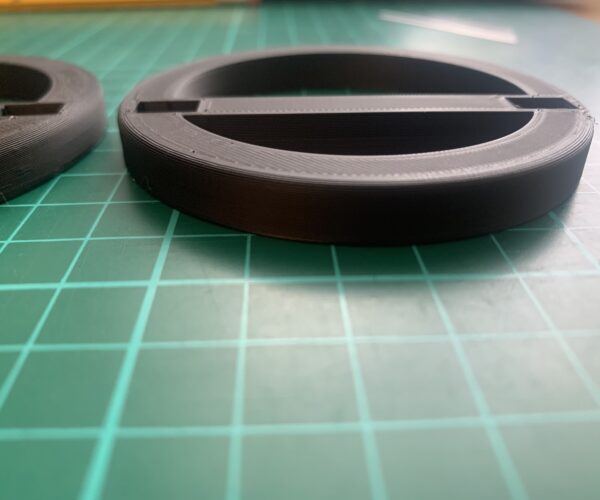

Initial results seem good, I had a project come up so I have to print on that I'll do more in a follow up. The following models were printed at 0.2mm Quality, Prusament PLA setting, but I modified it closer to the PETG settings. Under Advanced, I changed the volumetric to 7, and in Filament Overrides I matched to PETG Retraction speed = 40, Deretraction = 25, and minimum travel = 1. The results were pretty good so I'm going to use them as a base for more tests.

Low Poly Cat - Prusament Azure Blue PLA (ignore me forgetting supports on the chin, whoops)

XYZ Cube Reactor - Prusament Azure Blue PLA

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Hi,

a recently published video ( ) shows how and why an heatbreak can affect print quality.

Interesting

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

TL;DR settings at bottom of post.

Well, at least for me... I think I've finally reached the end of the journey. 😉 I've finally dialed in Prusament PLA on my MINI + Sock + Bondtech heat break with nice quality and minimal tweaks. After more changes and reducing tweaks to nail it down I ended up with this fairly nice benchy.

3D Benchy - Prusament Azure Blue PLA (0.2mm Quality)

This benchy came out so nice, and I especially love where the slicer put the Z movements on the stack, giving it a very light, but neat spiral up. The only issues here was some wispy strings, so I delved a little deeper since I seem to have gotten actual extrusion quality seated. Pay no mind to how the back of the cabin looks to bulge a little bit, it's the window in the back, it shows off how straight the layers stacked.

Stringing Test - Prusament Azure Blue PLA (0.15mm Quality)

Now we're getting somewhere nice. I couldn't see these strings with the naked eye, I had to turn on my flash and a ring light at max brightness to catch them. Smooth all the way up, less than spiderweb string just at the top, time for another benchy!

3D Benchy - Prusament Opal Green PLA (0.15mm Quality)

The Magnum Opus of this journey and final product of my work. The camera just does not catch how beautiful the Opal Green is, but I wanted to make sure to test a different colour to ensure the settings are for PLA and not just Azure Blue. Long broad surfaces, such as the bow of the boat are smooth, minus the infamous hull line. Retraction heavy areas, such as the cabin look good, and the short distance, heat concentrated areas like the smokestack are great. As for accuracy: Filament fits snugly in the flag hole in the back and absolutely no curling artifacts up front.

Now for the juicy parts; the settings that made the bondtech heat break actually work with Prusament PLA... In the end, it was actually quite simple and I'm surprised I tested a lot further (and while I ended up with good results in my last major post) than I needed to. Thanks to everyone along the way with their thoughts, ideas, and experiences. I hope these settings help you get good prints from Prusament PLA while retaining the thermal barrier protection of the upgraded heat break. If anyone has both Bondtech upgrades, heat break and extruder, please test and let us know.

Happy Printing! 🍻

Machine: Prusa Mini

Addons: Bondtech Heat Break, E3D Silicone Sock, RHD Fan Duct uploaded by bejotto

Filament: Prusament PLA

Filament Settings: Prusament PLA Based

Advanced Section; Max volumetric speed - 8mm³/s

Overrides Section; Retraction Speed - 40mm/s, Deretraction Speed - 20mm/s

Optional: Custom GCode - Linear Advance Tuning

That's it! It seemed to have been that simple. 🙃 If you do get minor artifacts/overextrusion, try dropping retraction to 2-2.5mm, but you may get a few more strings. As a note, the Azure benchy above had retraction of 1.5mm.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I had a clog these days that was building up over time when printing slower layers, then releasing itself in the not slowed down parts of the same layers. This looked like I had both, under- and overextrusion, at the same time. I solved this by switching to a larger nozzle diameter.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I will join the club: Have had some ongoing clogging / extruder clicking / underextrusion issues with my stock Prusa Mini. At first a PTFE tube exchange did solve the problem, but recently even this did not work out anymore in the end. So I finally ordered a BondTech heatbreak, reading one of the positive threads here and not noticing this and other negative ones.

So I performed the exchange and immediatly noticed some extrusion issues with a Benchy, stock Prusament PLA settings and the Lime Green Prusament filament. After some adjustments of the retraction settings I came to satisfacory results. Unfortunately, changing the Filament (DasFilament PLA) brought back some issues. I thought again that it might be related to the retraction values, as I mainly had underextrusion after deretraction / at restart. But printing some tests in vase mode lead to other - very interessting - results:

So it seems like the uneven extrusion is related to a certain resistance in the filament path which is dependent on the volumetric flow. Bigger layer heigts, bigger layer width, higher speeds and higher temperatur do improve the problem. Any ideas what might be the underlying cause?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

These are my settings for PLA, before that I just had problems mainly due to the standard retreats.

I installed the following:

- BondTech Prusa Mini Extruder

- BondTech Heatbreak Prusa Mini

- Capricorn XS Series PTFE

- trianglelab T-V6 Plated Copper Ruby Nozzle

And M221 S90

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

So far I have been able to achieve good results with 0.2 or even 0.15 and standard print settings with different types of PLA.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

So far I have been able to achieve good results with 0.2 or even 0.15 and standard print settings with different types of PLA.

This is the case, every other PLA prints perfectly fine, the issue presented here is very much a Prusament PLA problem for some reason. YMMV of course, but this was the case for me. I only had to build a specific profile for Prusament PLA, every other PLA I run at the generic settings at any layer height just fine, only change I make is temp depending on if I want details, or structure.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

With Prusament... I've tried the settings from @daniel and @skreelink and they don't work at all for me. 🙁 I actually stopped the Benchys before they even finished the archways.

The only thing that seems to really make a big difference is increasing the temperature for Prusament to 230C, which feels way too hot for PLA. Every other brand of PLA is just fine with Generic PLA settings (or AmazonBasics PLA).

Generally, every Benchy is fine until it gets to around the porthole, and then depending on settings (this is where it retracts a lot I think) it can be absolutely terrible all of a sudden.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

With Prusament... I've tried the settings from @daniel and @skreelink and they don't work at all for me. 🙁 I actually stopped the Benchys before they even finished the archways.

The only thing that seems to really make a big difference is increasing the temperature for Prusament to 230C, which feels way too hot for PLA. Every other brand of PLA is just fine with Generic PLA settings (or AmazonBasics PLA).

Generally, every Benchy is fine until it gets to around the porthole, and then depending on settings (this is where it retracts a lot I think) it can be absolutely terrible all of a sudden.

I bumped the temps all the way up to 250 degrees and got a nice benchy, I wouldn't worry too much about 230C. Silk PLAs tend to do well in this range (I normally run 220-225 for silk PLA) and since Prusament already requests higher temps at 215 default, 230 should be about right since the bondtech heatbreak creates a shorter melt zone by having a proper hot/cold zone cutoff instead of allowing heat to travel up the heat break to pre-soften the PLA. The same effect of slower or lower retractions is what I figure, keeps the end in the hot zone longer, which is why higher retraction areas, or fast moving areas (where it's just pumping it quickly) seem problematic. Whereas the higher temps lets it simply melt faster to compensate. The way it's Prusament PLA only is still a strange stickler to me... Try a mix; reduce retractions to say 2.5mm, speed to 40, and temps at 220-225 and see how that works out.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.