SE Mosquito

Anyone here have the Mosquito installed? Looking for some reference pics for install, some feedback on how its doing and tips. I'm pairing it with the Bondtech extuder, the E3D Nozzle X. and a 50W heater cart. Printing a lot of PETG, ABS. Looking to get to ASA, carbon fiber, PEEK.

RE: SE Mosquito

I had to go and look this up. Nice design. Looks like it it could be so long that the Z-range (max height of the printable object) might get reduced a little. Would be interesting to try, but the upgrade with shipping to me costs US $292, + local toll and taxes. So no thank you.

That hot end looks to be real good, but I wonder if Prusa Mini is the right platform for such a beast. It might be excellent choice for the upcoming Prusa XXL with 1 m³ of printing volume. There with a boosted extruder and large nozzle it would be in right place. It's also possible that for such a beast of a machine those hot ends come as a standard (hot swappable hotend to print large volumes quickly but still be able to go high detail where needed).

I would not be surprised if Prusa would co-operate with SE to come up with a hotend and nozzles for vectored printing with 5-axis printer to get real 3D printing for this beast.

RE: SE Mosquito

@lupin

It was only $175 with the hotend, 50W cartridge and their thermal paste. They are just 2 states away from me here in the US so shipping was free.

im going to install it, SE has it listed as a hotend that’ll work with it. I’d doubt they’d sell something that wouldn’t work with the printer. They even have a supported file for the adapter to the mini. It only adds 11-12 grams. Something the z-axis should be fine to manage, those 2 smooth rods and threaded are quite thick. Though that would be a great idea! The Mosquito has the 2nd option of the ceramic insulator so that would prints some serious stuff extremely quick. The Volcanoes have nothing on the Mosquitos temp. 500C rates is insane especially out of a 0.4m nozzle.

RE: SE Mosquito

Te Z-axis has enough power, sure. Thread is not so sensitive to some extra weight. And I did look at the adapter they have in Thingverse. 500C is good, you can replace plastic filament with tin and make metal prints (better upgrade the fan).

Please report back on how it goes, interesting setup although not really sensible for me. The price I listed was for the full upgrade kit for Mini, shipping was about US $52.

If I need to get lots of parts out quickly, I rather buy another printer. Compared to what the upgrade would cost to me, especially if one buys the Bondtech extruder too, another mini is roughly same price. We'll see what Prusa comes up with next, the XL is interesting, but I might wait for the XXL

RE: SE Mosquito

@justin-10

Someone has SE Mosquito on Mini, check this out: https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/different-hotends/#post-220930

RE: SE Mosquito

@lupin

Yeah ill definitely post pics. Since I’m in the US shipping was free for me. $174 wasn’t bad for the print temps and I don’t do much PLA. ASA, ABS, PETG and Nylon are my go to in the textured sheet.

not sure what filaments I can even pump at 400C+. I did go for the stronger heater cart too so how sway in the temp at 50W over the stock 40W.

RE: SE Mosquito

AFAIK Peek and PEI are the only ones you use over 300C for. But I'm a noob myself, what do I know. 🙂 Stronger heater cart might be pushing it in Mini, it's power source does not have much leeway to my knowledge. You'll likely get away with bare 10W more unless you have other power hungry modifications done.

RE: SE Mosquito

There's an article in the net about using high temperatures, looked to be quite good: https://www.3d4makers.com/blogs/news/turning-a-desktop-3d-printer-into-a-high-temperature-printer

RE: SE Mosquito

@lupin

Nope, nothing power hungry. All I have is the Bondtech extruder. All my other stuff is powered on it’s on. Stock is a 40W heater, 50W should be fine. The meanwell is a good and efficient PSU. And like I always like to believe, a company like SE wouldn’t sell parts they didn’t believe would work with the printers, especially when they are marketed as upgrade parts for that model. Law suit waiting to happen if it didn’t.

RE: SE Mosquito

@lupin

Oof, those bed temps are insane. 120C minimum for this heigh end. Though now I could most definitely hit well over 400C on my hot end.

I may indeed try and play with the settings to see if I can change the Prusa firmware which maxed my Mini+ at 290C. For the mosquito that’s like a nice summer morning.

RE: SE Mosquito

@justin-10

I think you are right. The weakness of the mini is bed temperatures. I could be wrong but I do not see 120 C.

--------------------

Chuck H

3D Printer Review Blog

RE: SE Mosquito

@cwbullet

Nope, 100 C is the maximum now. Some of the PEEK and other filaments need that extra 20 to 30 C which maybe could be achieved through 100C mixed with a binding agent to make sure it doesn’t move off the sheet. Similar to ABS juice.

RE: SE Mosquito

@justin-10

I have had mine up to 100 C. I have printed PC Blend at that temp. It is not ideal but it does work.

--------------------

Chuck H

3D Printer Review Blog

RE: SE Mosquito

@justin-10

Someone has SE Mosquito on Mini, check this out: https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/different-hotends/#post-220930

That 'Someone' is me, and the mount you are referring to is for the Copperhead NOT the Mosquito. Just want to make sure everyone is on the same page.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: SE Mosquito

I had a standard Mosquito that I intalled on my mini clone. I had to rebuild it and never put it back,

The clone is where I test hotends.

--------------------

Chuck H

3D Printer Review Blog

RE: SE Mosquito

@justin-10

Let us know how it works out for you.

--------------------

Chuck H

3D Printer Review Blog

RE: SE Mosquito

@cwbullet

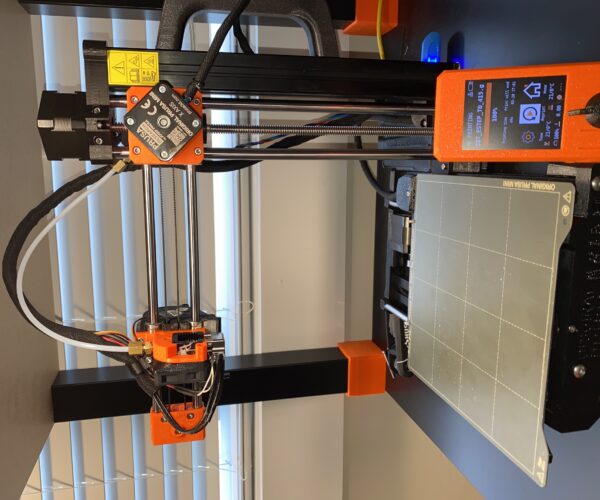

So far really well, it was a big leap. Once you start taking it apart if you don’t have everything on hand you could be flustered. I double checked my screws, nuts, printer adapters. Ended up taking about an hour, included removing the hotend completely, rewiring a new 50W cart. Wrapping around the cable cluster was finicky but went back on proper.

handling 80 degree over hangs better. Better stable temps and now heats faster. I did have to modify the g-code for the purge line though that was very simple. For some people I could see it be coming the death of their printer and others, a great success like me.

P.S. It also looks really beautiful the printer!

RE: SE Mosquito

@justin-10

I have 2 on my Mk3S printers. I had on a Mini, but never say the benefit. I might have quit too soon.

--------------------

Chuck H

3D Printer Review Blog

RE: SE Mosquito

@cwbullet

I never find myself changing any settings, less stringing. It just prints the first layer very smooth, something I could get on my stock but on certain areas not all over for multiple pieces.