RE: Revo Micro installation on my Mini+

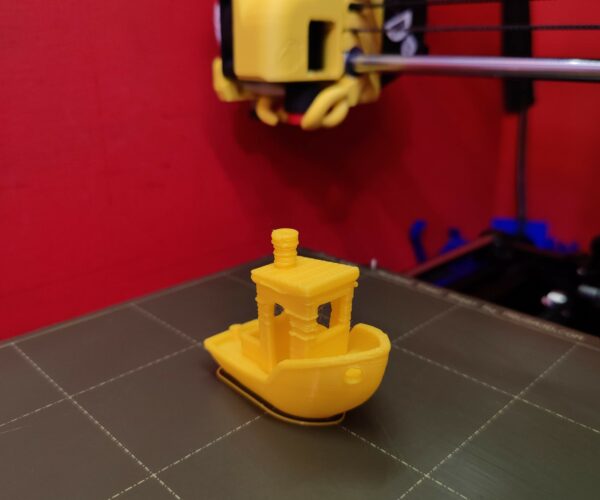

Let’s see. I’m printing a Benchy with 100% hot end fan speed at the moment (custom firmware).

RE:

Before putting the Revo on, and after reading a number of posts on the shorter ptfe tube causing binding and extruder clicking, I put on a new blue (capricorn?) ptfe tube. I didn't measure, and I know I should have, I gauged the length by putting the hotend all the way to the end of the x-axis and cutting where it looked 'okay'. I'm running 3.2 mm @40mm/s for retraction. I also have the Bondtech IFS Extruder on the mini. My start gcode is using both the pid and esteps recommended by Bondtech. Prior to the hotend exchange, I also had the heatbreak upgrade kit from BMG installed. The original setup ran for almost a year with 2 clogged nozzles, one of which was certainly my fault(I had printed almost an entire Voron 2.4 in ABS and switched to PLA). Not sure on the other clogged nozzle. Only had the clogging issue with PLA with the Micro, like almost everyone else. Up to the issue, I had run 3 rolls of htpla through it, switched to petg and ran about a roll of it through the mini and finally switched back to pla to finish up the project and then had the issue. When the clog happened, I checked the resistance on the thermistor to eliminate that as an issue and it was 91.6 at room temperature. I thought I had cleared the clogged nozzle, but in retrospect, think I did a poor job. It was under-extruding after the clog and I attempted to adjust it out using live-z adjustments. Nothing good came from that path. Changed out the nozzle and have had no issues since but have not printed with any filament types other than PETG so far. I have no issues with quality of print with this nozzle, it prints PLA and PETG really well. During printing, I have observed the ptfe tube lock rotating on the hotend end of the tubing. It is not moving up and down, just rotating about a quarter turn, but it is noticeable if you are looking for it. I did make sure it was seated downwards and it all seems okay. Is this a potential issue?

RE: Revo Micro installation on my Mini+

Depends on the filament I think. Hotter filaments seem to have no issues and PLA depends on the type. Considering I get the same issues in the six and micro but not stock v6 would lead me to think something is not right.

RE: Revo Micro installation on my Mini+

What about your other posts where you said PLA prints like crap? Did you solve it?

RE: Revo Micro installation on my Mini+

Let’s see. I’m printing a Benchy with 100% hot end fan speed at the moment (custom firmware).

If the issue is part cooling, not sure the hot end fan speed would be relevant. Part cooling fan would already be 100% due to PLA profiles.

RE:

Thats a reasonable idea but on my benchy pillars at the minute I get worse errors on the fan side, also these errors all vanish on higher temp materials or even PLA that is stiffer than normal which leads me to think my issues are with the filament being fed into the hotend causing the inconsistent over and under extrusion on areas with lots of retractions. Unfortunately the spare ptfe I had to test this is no good as it's the wrong extremal diameter and the brass olives slip loose before the benchy completes.

I'm seeing worse artefacts on one or the other side when I print the benchy. Seems random which side, at least in my tests.

I don't think the issue is necessarily higher temp, but lower cooling flow. Non PLA (that I am aware of) all require lower cooling flows.

While I see you guys chasing down the PTFE route, I can't help thinking that this will be the same for other material - filaments are the same diameter. My PETG benchy printed perfectly every time. My reasoning would be that tube related friction would be a constant effect, regardless of temperature, since the PTFE path ends some distance away from anything that is hot.

A relevant question at this point would be what extruder you are using. Stock extruder may well be more susceptible to PTFE issues than, say, the Bondtech extruder.

(Edited - PETG benchy of course - too may acronyms!)

RE: Revo Micro installation on my Mini+

Your not wrong. I was clutching with the hot end fan speed as 100% (opposed to the Prusa default of 38%) killed the print after the first few layers. Going after part cooling now with a remix I found.

RE: Revo Micro installation on my Mini+

Bondtech IFS, Capricorn ptfe and a M8 to M10 pass through adapter which is rock solid. I think your right but I did have issues with the ptfe. Loads of movement at both ends which I’ve now resolved with the M10. I’ve not run the stock setup for over a year. Previously this was mated to a V6 from an old MK3 with stock x-carriage and a hotend bracket that dropped the v6 3mm to align with stock part cooling duct. I noticed the micro and six nozzles sit lower than the v6 did so I’m now thinking part cooling/over cooling. PETG at default 76% cooling fan speed does print fine.

RE: Revo Micro installation on my Mini+

That benchy was with Overture PLA, I have had equally good prints from Eryone PLA.

RE: Revo Micro installation on my Mini+

So today I took a methodical approach to try and narrow down the culprit, first I kept everything the same but did new PTFE tubing which made no difference, however the old PTFE tube was visibly damaged by the connector into the revo so next I installed lichtjaegers V2 mount alternative so I could have a decent fan and a brass nut connector and while I feel better having a more secure connection of the PTFE tubing it made no visible difference to the model so lastly I installed lichtjaegers antler blower, which while I am not a fan of the small height difference between the nozzle and the antlers has at least made a visible improvement in the parts of the benchy that were already ok, however when it got to the pillars I got exactly the same problem.

So, PTFE didn't fix, cooling didn't fix, the only thing that has made the slightest difference is slowing the hotend fan a silly amount or printing at too high a temperature for vanilla PLA which leads me full circle to many small retractions on a bowden system at already low temperatures *rapidly* cools the inside of the revo filament reservoir leading to under and then over extrusion. I think it's a straight up design flaw which we cannot correct for.

One day of experiments and all I have to show for it is this poor benchy.

RE: Revo Micro installation on my Mini+

I still haven't fitted mine yet, but things I would consider trying next are...

Decrease retraction length to 1.8

Slow down if layer print time is below (decrease)

Min print speed (increase)

RE: Revo Micro installation on my Mini+

I still haven't fitted mine yet, but things I would consider trying next are...

Decrease retraction length to 1.8

Slow down if layer print time is below (decrease)

Min print speed (increase)

THIS PERSON IS A WITCH AND WE SHOULD HUG THEM!

I genuinely can't believe going too slow and printing with what I thought were safe defaults is what has been causing all of this but here we are 48 minutes later with a near perfect benchy.

RE: Revo Micro installation on my Mini+

What settings did you change?

RE: Revo Micro installation on my Mini+

Well I saw where he was going with the suggestion, so I switched back to my fast klipper profile I was working on before the revo arrived, things it changes from the default .2mm profile are a modest bump in all mainline speeds to 60mm/s, only slows down for cooling if layer time is less than 5 seconds and disables all acceleration controls in the slicer so klipper can handle that better.

I'll run a few more tests tomorrow and then get input shaper tuned to cancel out the increased ringing (something that had vanished on the super light V1 E3D mount but no way I'm going back to that collet clip arrangement for my tubing).

RE: Revo Micro installation on my Mini+

She is a witch, but that's another story...

I think what is happening is when the mini slows down at the structures where it is no longer travelling to the bow, it just keeps oozing out of the nozzle due to the pressure build up in the bowden tube.

RE:

Wonder why none of the Revo Micro beta testers or E3D reps are chiming in on this thread to share their experiences and work around a if they encountered similar issues…

seems like we are on our own to sort this out.

RE: Revo Micro installation on my Mini+

She is a witch, but that's another story...

I think what is happening is when the mini slows down at the structures where it is no longer travelling to the bow, it just keeps oozing out of the nozzle due to the pressure build up in the bowden tube.

I'll go with genius 😊

I am a bit new to this, looking at Prusa Slicer setting for filament I can't see an obvious setting that would address this. Would it be possible to give me some pointers?

I'm with the stock Mini firmware - not interested in changing it. So I'm assuming the slicer filament settings are the correct place to go.

RE: Revo Micro installation on my Mini+

In prusa slicer I'd set the filament overrides in the filament section to reduce retraction length (1.8) and in the cooling section reduce the minimum layer time down (5 seconds) and minimum print speed (25). This should get it printing and then you can tweak.