RE:

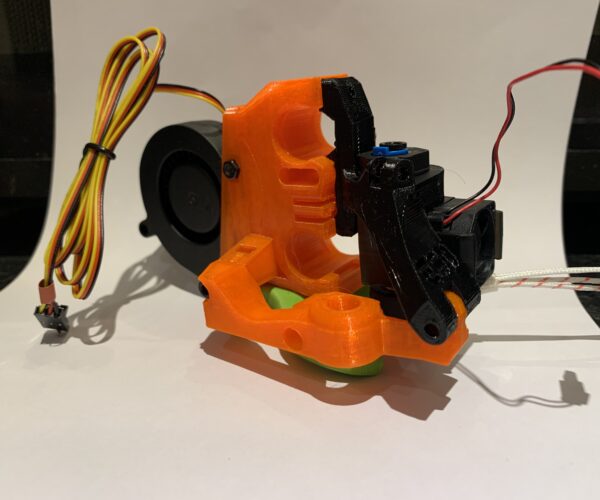

I hope to install mine in a few days, I also made this cooling duct modification. I've already printed it in PETG ready to go, I just need to get some good examples of cooling problem models printed so I know it helps.

Seems like the benchy roof pillars are a good example of PLA cooling issues 😀

Would you be in a position to share your ducting design? I've had a good search and can't find many for the Mini. Antler design by @lichtjaeger seems to extend a bit far down (also mentioned by @sp4rkr4t).

RE: Revo Micro installation on my Mini+

I had to guide the airstream below the silicone sock and to the nozzle tip. It's similar to the SPINDA height. So, there shouldn't be a problem. 🤷

Antler design by @lichtjaeger seems to extend a bit far down (also mentioned by @sp4rkr4t).

RE: Revo Micro installation on my Mini+

Would you be in a position to share your ducting design? I've had a good search and can't find many for the Mini. Antler design by @lichtjaeger seems to extend a bit far down (also mentioned by @sp4rkr4t).

As soon as I have everything worked out and tested I will definitely share it. I hit a few snags since fitting it, firstly I had to redesign it because the base fouled the plate backstop screws, then I've had to redesign it again because the nut/bolts that hold the fan hit the Z bar when homing the X axis.

And my V-Core 3 was temporarily out of action so printing test parts has been difficult without a printer. 😂

All I can promise is soon!

My plan is... test it with stock, then fit my revo and test it with that (because I suspect the revo may need a lower duct.

RE: Revo Micro installation on my Mini+

I’m subscribed to this thread. I’ve the same issues. Already had a failed thermistor. Tried the v2 mounting part. Tried the antler duct. Tried reducing overall cooling part fan speed. Benchy ails at the cabin with a clog and only on PLA. I had a perfectly fine working v6 mod which I’m contemplating going back to.

RE: Revo Micro installation on my Mini+

I got the revo micro installed and have run it almost non-stop since. No issues at all. Then, last night, I switched out some Protopasta for Matterhackers PLA and about an hour into the print, extruder started clicking indicating. Turn up the nozzle temp a little and it stopped, then started about an hour later. Did the same again and now the nozzle temp is up to 220 and it's still clicking. I did notice that the temps reported were lower than i expected (from the screen). How do i tell if my thermistor has developed a fault? Thanks.

RE: Revo Micro installation on my Mini+

You can use a multimeter to see if the thermistor is gone.

https://www.help.prusa3d.com/en/article/multimeter-usage_2117

Just make sure to have the thermistor unplugged from the board when testing. When my first one dies it was 250kΩ which is way out the good range.

RE:

It also appears to be under-extruding. I redid the offset after reading about a possible loose pinda probe as the cause and now my z-offset, which was at -0.190 is now at -0.785 to even come close to a good first layer(still had some issues but it was a good start). I will shut down and test the resistance as you noted and then get back to you. Oddly enough, Matterhackers sent me the wrong Revo for my sons MK3S so I actually have an entire spare Revo Micro on hand that I haven't sent back yet.

Up to this issue though, the Revo has been awesome. I'm down to a few remaining plates for my 3dsets Buggy RC car. Used a combination of PETG and PLA (Protopasta Cloverleaf Green - not supposed to be abrasive but I put 3 rolls through the revo .4 nozzle).

RE: Revo Micro installation on my Mini+

I did some small stuff with the V1 bracket and PET looked good. Trying some Inland white PLA, and it is printing like crap. Underextrding, but no clicking... Setting: Standard speed .2 mini setting, generic PLA- and I bumped the extrusion up to 104%, and the temp up to 235, speed - 80, then 50, now 25%. It's better, but it is still under extruding on layers, perimeters seem OK.

Haven't seen prints this bad since I retired my old PRintrbots...

For a printer that was printing pretty perfectly before this, only swapped because I nicked the old thermistor wire and it was throwing odd temps.

RE: Revo Micro installation on my Mini+

This micro isn't right. I don't know if it is, but I have two stock Prusa Mini's except one has the V1 (mini fan) mount. I tried to do a PLA print in the E3D REvo mini, and it failed. In retrospect, I think it was clicking. I could get a better print if I heated it up to 230-240 (I think 240 was too high) and slowed it down to 25% of the standard fast PLA generic print speed. That print eventually failed, clogged up- I think the 240 was just too high.

I then took the same g code and same Inland white PLA and printed on a stock mini. No problems at 100% speed.

I then took the g-code for the E3D V2 REvo Mini mount in PETG, and printed that with Prusament Black PETG. Absolutely beautiful. Nice print.

So does that mean that the PLA is getting soft and causing issues due to heat creep? One thing I did notice as I slowed things down, as it shifted from perimiter printing to infill/layers, that the most errors/holes came right after the that switch. After it started printing the solid layer (linerally 50mm?) it would start to print better. The print was diamonds 40x20mm, like 12 in an array. So it had some fairly short runs. It failed (stopped feeding and ground up the filmanet. When it started printing a 2mm thick wall on each diamond. (think of an upside down lego brick, but in a diamond shape). So fair amount of movement and retractions for volume printed.

But like I said, the stock printer printed it fine. Re-printing on the stock printer. I might try the print on the REVO again, and then maybe in PETG. Just to run the 2x2 matrix of machine and material.

THis weekend I'll be installing the stock fan on the V2 mount. It sure seems like the Micro is just too short and not 'windy' enough for the Prusa. Maybe the fan can be sped up??? I can't believe that they let this out with it not working with PLA???

RE: Revo Micro installation on my Mini+

It's not as simple as heat creep though, I have the V2 mount on as the revos small fan could stop if something touched it during operation and didn't have the grunt to get going again and I'm still having nightmares with PLA. I did manage to get a few prints to a passable standard in PLA by modifying the slice profile to keep the volumetric flow rate as consistent as possible, this meant slowing infill right down, making external and internal perimeters the same speed, etc. This works but its far from ideal.

The issue seems to be the temperature of the inside of the hotend jumps massively when printing with low temperature materials and demand on the nozzle varies. Until this is understood better I'll just shuffle my projects around to only print the ASA/PETG ones.

RE: Revo Micro installation on my Mini+

did you check resistance measurements accross the thermistor and heater ?

It's not as simple as heat creep though, I have the V2 mount on as the revos small fan could stop if something touched it during operation and didn't have the grunt to get going again and I'm still having nightmares with PLA. I did manage to get a few prints to a passable standard in PLA by modifying the slice profile to keep the volumetric flow rate as consistent as possible, this meant slowing infill right down, making external and internal perimeters the same speed, etc. This works but its far from ideal.

The issue seems to be the temperature of the inside of the hotend jumps massively when printing with low temperature materials and demand on the nozzle varies. Until this is understood better I'll just shuffle my projects around to only print the ASA/PETG ones.

RE: Revo Micro installation on my Mini+

E3d is touting this modification as using the same set of screws as the standard equipment, so you don’t even have to buy a few M3 bolts. If they think they have that kind of customer base that can’t source M3 hardware, do you really think that testing the resistance across those is going to be anywhere near that Target market skill set?

RE: Revo Micro installation on my Mini+

Yes this is my second revo micro, the unit is reading correct and like everyone says this issue is only affecting low temp materials like PLA.

RE: Revo Micro installation on my Mini+

Is the issue that the heat break is just too short? People that used the full size REVO, are they seeing the same issue?

And I’ll whisper this- if the Prusa new system is related to this, are there going to be issues there…..

RE: Revo Micro installation on my Mini+

I tried the bondtech heatbreak with my mini's original hotend and that did not solve my heat creep issues, this one appears to be longer...

Is the issue that the heat break is just too short? People that used the full size REVO, are they seeing the same issue?

And I’ll whisper this- if the Prusa new system is related to this, are there going to be issues there…..

RE: Revo Micro installation on my Mini+

Just finished checking the resistance. On a Fluke 101 the resistance was 91.6, so well within tolerances listed on the Prusa knowledge Base Article. Is it possible that by running almost 3 rolls of the Proto-pasta HTPLA through the mini, along with several rolls of PETG, if I've just worn out the nozzle. Next thing to try I suppose. Gonna get expensive if this happens often.

RE: Revo Micro installation on my Mini+

Is the issue that the heat break is just too short? People that used the full size REVO, are they seeing the same issue?

And I’ll whisper this- if the Prusa new system is related to this, are there going to be issues there…..

The only difference between the V6 and Micro is the heat sink. V6 is the same form factor as the existing E3D V6 hotends for a drop-in replacement. The Micro is a smaller, specifically-designed heat sink with new mount. There's a Voron Edition with even slightly smaller custom heatsink coming soon. AFAIK the heatbreak part is the same length as existing V6 style setups.

I have a Micro in my Voron Trident and have had zero issues with it, mostly running ABS at 240-255C and multi-hour prints. I am using a 40x40x20 fan and not the tiny one E3D sent with the hotend.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE: Revo Micro installation on my Mini+

Quick Update - I replaced the nozzle on the micro, checked the z-0ffset by running the wizard and have started to print the V2 Edition of the mount. Up to this issue, I had run multi-day prints with HTPLA, PETG and PLA and had no issues. It just worked beautifully.

The issue started as I finished one plate of HTPLA and switched to another color of MH PLA Pro+, and as I wrote in my original post, an hour into the print the clog started(NOTE: I've had NO issues with MH filament prior to this issue, it's great stuff). I tried bumping the temp on the nozzle and reducing the print speed with no success. I was not able to get a decent print after that, no matter what I tried, until I replaced the nozzle. Checked the resistance on the thermistor as suggested (91.6), no issues with it.

Going to switch out V1 for V2 this weekend to see if that will help.

RE: Revo Micro installation on my Mini+

OK right now I've got my PLA filaments working on the V2 mount, however it's not a solution for people running the stock prusa firmware as under the standard firmware the hotend fan runs at 50%, I have PLA printing nice again with the hotend fan set to 30% and I don't seem to be getting any issues with temperature swing on short extrusions and the benchys are printing fine again.

Since I run klipper I've ended up making multiple printer.cfg files and switch between them for different materials and nozzles, it's not elegant but it works.

RE: Revo Micro installation on my Mini+

The same result could be achieved compiling llama mini firmware (assuming you want to hack your mini) adjusting the code for the hotend fan speed. It’s already got settings for multiple higher hot end fan speeds but nothing lower than default 50%. A code change and compile would fix that but it’s a ridiculous approach to what’s clearly a failed UAT by E3D. I’ve removed mine for now.