Yes

Will do.

Yes you do and it would be nice if you post a picture and tell me how it goes. So we can make improvements if needed. What extruder are you planning to use?

/Tomson

--------------------

Chuck H

3D Printer Review Blog

Got Problems...

Hello,

After building my mini bear I have two problems left.

The first one is a underextrusion in the first two layers, which leaves horrible surfaces, and the second one is the filament Sensor working the wrong way in detecting missing filament, with the FS lever from this project...

Has anyone some ideas for me to solve those problems?

Greets David

Fs lever

Hello

With the FS lever mirrored from the prusa Bear Mini Files the Sensor is triggered with Filament in the Extruder and in the Mini Software and the Mini Filament Sensor the Trigger is Set without Filament in it....what is the solution for this?

Regards David

FS-Lever

Hi David.

I tried it myself with the filament sensor the other day for the first time. Have not used it before and discovered the same thing as you. I am working on a new extruder for 20mm thick Noctua fan for the hot end. But I think I will be done with it by the weekend then I can see if we can rebuild fs-lever to reverse function if someone else does not have time before 🙂 Did you make your MINI-Bear with your 30x30 extrusions? If so did you use the alternative Z-axis? A little curious if someone built with 10mm z-axis Best regards/Tomson

FS-Lever

Hi David. I made a new FS-Lever with reverse function. It´s a little weak but i wanted to fit the OEM housing. I have tried it on the MK3 extruder for the MINI-Bear : https://www.prusaprinters.org/prints/68537-mini-bear-remix-and-spoolholder-and-filament-feede and it worked fine. Maybe i do another one later and make some changes on the housing as well. but i also added it to the extruder with OEM MINI heatsink. I have not tried it with that one but it should work to. https://www.prusaprinters.org/prints/74880-mini-bear-direct-drive-stock-extruder-and-hotend . What extruder are you using? Regards/Tomson

Looks good

@Tomson,

I'm using all of the Files you brought together. So i have got the same mirrored Standard prusa Design Extruder like you. i wanted to build the second printer in Haribo/Zaribo Style, but struggled with the time without progress of this project and for my "wrong" bought profiles....so i took the Money and bought a second frame out of 2040 profiles finally. Maybe it is better to have two identical machine when it comes to troubles, holding wear parts in stock and so on...

So now i'm building the second machine in the same way like yours and try to solve the last few micro problems left 😉

Thank you for your Help until Here and in advance

Best regards David

8mm on all axis

@Tomson

After purchasing complete Sets of Lm8uu from IKO brand I decided to go with 8mm in all axis. The lm10 from the Chinese Clone kit are horrible, so taking a decision was easy 😉

Kind regards David

FirstLayer

Yes i think is better to have more identical printers, less spare parts to keep them running. I have had my share of heat creep as well so i bought parts for a extra complete extruder for easy switching. Working on a new extruder with 20mm Noctua fan to eliminate that problem ones and for all. Looking good so far and gonna share it later when it feels complete. It would be nice if you posted some picture, always fun to see others build Good luck with the new build. Regards/Tomson

Profile Extruder steps

@Tomson

Is your printer working with one of profiles from Here?

After i do first layer calibration and afterwards print with the profiles it starts somwhere in 2mm layer height...And i ve got terrible underextrusion...

How does it work on your printer?

Regards David

Underextrusion

No i don´t have problems with that. I use pear.3d:s https://www.prusaprinters.org/prints/37939-prusa-mini-mk3s-bear-ultra-upgraded/files

RE: Prusa Bear Mini Mk3s

Thanks guys for all your hard work

This looks a great mod.

A few questions if anyone can help please?

I'm going to order the specific mini bear upgrade kit from aliexpress from blurolls.

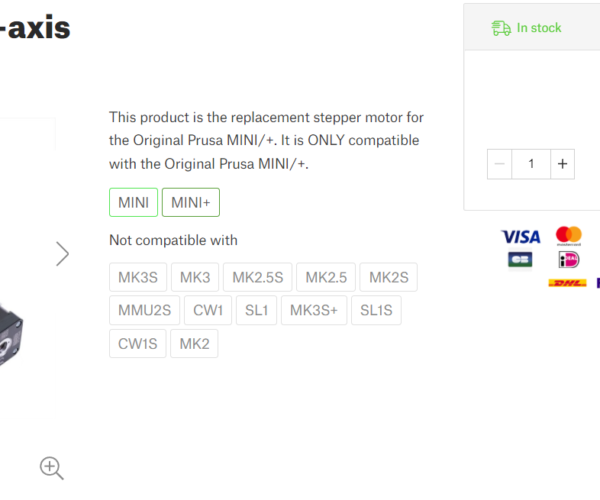

I want to use my current mini Z and smooth rods as i'm not bothered about gaining for height from Z, so will print out the stuff kindly provided by tompson for that.

I will order a new official Z motor from prusa.

Do I need to order new belts for X and Y and new bearings etc?

What is a good new entire hotend with direct drive to get? one from aliexpress or?

This new direct drive hotend will fit on the mini X smooth rods and belts?

I just want to make sure I get everything ordered at once as the postage costs are very high.

here is what i currently have, any help with what i still need please, hotend etc, can i get the hotend from some other company or?

@3dpgva

Hi again. Yes the stoplimit i found out yesterday than i did the wizard. I put some temporary limits but i think i put them 1-2mm to high. I was to exited to start printing so i save that for today:)

@firstlayer

Hello there, can you show a picture of printed part and the profile, and we changed the name to pear3D now 😀

RE: Prusa Bear Mini Mk3s

Oh i also forgot to ask,

now that you can change extruder steps in mini firmware since 4.3.3 does that mean you need no mods or gcode to insert now before running a job?

does the extra motor for the Z require g code?

thanks

RE: Prusa Bear Mini Mk3s

now that you can change extruder steps in mini firmware since 4.3.3 does that mean you need no mods or gcode to insert now before running a job?

-that's correct.

In your previous post you ask a lot of questions regarding BEAR upgrade. Some of them only author of the project can answer, because it depends on what kind of changes have been made. New belts, for example? As said, depends on project.

If you think about making additional changes (different hotend, direct drive extruder, etc), then all that adds to complexity.

Keep in mind, that original firmware only supports extruder settings. Any other changes (hotend, for example) might require custom/modified firmware.

What I'm trying to say is, before you make any purchase, you need to be absolutely familiar with the process: what parts are needed, how to assemble the machine and what firmware changes are required -all steps must be answered in your head.

Btw. I assume you have all necessary tools in your workshop.

[Mini+] [MK3S+BEAR]

RE: Prusa Bear Mini Mk3s

Thanks

I just ordered all the parts from aliexpress above along with a mk3s+ complete hotend.

I ordered the mini Z motor from prusa 🙂

Can't wait to give this a go.

Thanks all

RE: Prusa Bear Mini Mk3s

Congrats for your purchase 😀 .

[Mini+] [MK3S+BEAR]

RE: Prusa Bear Mini Mk3s

@jmac,

hello there, there are some important stuff to keep in mind z steppers should be identical prusa original or aliexpress (bang thing or whatever), extruder steps you dont need to change the printing profile is on the prusa printers under my projects, you can get x axis mod from @Tomson and he did very good job there, for the z wiring there is also instructions on my profile. After this i can say enjoy the mini beast (release the kraken) 😉 cheers

and happy printing

RE: Prusa Bear Mini Mk3s

Hi pear3d.ch

I would just like to say thank you so much for all your hard work 🙂

Yes I bought a original mini from prusa so I also ordered my Z stepper from them to match my current one,

The x axis mod looks good 🙂

One thing I wondered as someone told me that the bear mod parts require wider shaft for the gear pulley on X and Y ? I can't use my current mini ones?

Thanks

RE: Prusa Bear Mini Mk3s

Hi again @jmac,

can you please share a picture i dont recall it to be different, i will have a look at that.

cheers

RE:

Hi again

From what i can make out the bear 2.1 specifies to use a smooth shaft pin for the idle pulleys, instead of using a screw as prusa use.

No issue you could use either, I have some smooth shaft dowels coming with my kit anyway so I will use them 🙂

https://github.com/gregsaun/prusa_i3_bear_upgrade/blob/master/doc/bom.md

click to see full picture 🙂