RE:

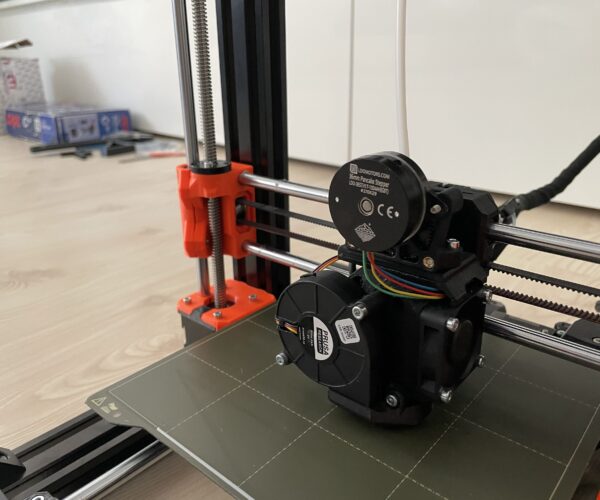

Not really. You may need to move the Super pinda a bit. I find that out than i mirrored the Hurricane to MK3 🙂 I have not made an effort to move offset or change the cadfile yet.

I belive what you see looks cleaner is the mount for the printfan. That was what Mk2 looked before. It´s not perfect for the airflow and i believe it´s a reason why Prusa change it.

Hi 🙂

I'm still waiting for some parts on my mod 😐 but just read this and got me worried a bit. I want to use the Sherpa Mini extruder in a combination with a E3D Revo (Voron heatsink, to rigid mount it - I also have the Micro heatsink but I find the thread mount fiddly, don't really like it) and I started from a Exxa extruder because I liked some screws positions :))). If you have some time, can you detail what I need to change? is that a critical change - won't work without it?I ask because I have just one printer 🙂 if I tear it down just to find out something is wrong, it won't be that fun :)))

this is what I have so far, step file available here: https://www.printables.com/model/201600-wip-prusa-mini-bear-sherpa-mini-revo-voron

RE: Prusa Bear Mini Mk3s

Not really. You may need to move the Super pinda a bit. I find that out than i mirrored the Hurricane to MK3 🙂 I have not made an effort to move offset or change the cadfile yet.

I belive what you see looks cleaner is the mount for the printfan. That was what Mk2 looked before. It´s not perfect for the airflow and i believe it´s a reason why Prusa change it.

Hi 🙂

I'm still waiting for some parts on my mod 😐 but just read this and got me worried a bit. I want to use the Sherpa Mini extruder in a combination with a E3D Revo (Voron heatsink, to rigid mount it - I also have the Micro heatsink but I find the thread mount fiddly, don't really like it) and I started from a Exxa extruder because I liked some screws positions :))). If you have some time, can you detail what I need to change? is that a critical change - won't work without it?I ask because I have just one printer 🙂 if I tear it down just to find out something is wrong, it won't be that fun :)))

this is what I have so far, step file available here: https://www.printables.com/model/201600-wip-prusa-mini-bear-sherpa-mini-revo-voron

pfiu! it worked 😀

RE:

Hey Tomson.

Have you sorted out the heat creep problems? Im using the hotend fan from the mini and I cannot print PLA longer than 10 Minutes and extruder starts to click. Im guessing it has to to with heat creap? The funny thing is that I dont get a glogged nozzle when it happens.

I did try out literally anything to get PLA printing again but extruder keeps clicking. Hotend fan not having enough power or defect stepper motor are my last options, atleast thats how Im feeling at the moment.

Best, Anxodia

RE: Prusa Bear Mini Mk3s

Hey Tomson.

Have you sorted out the heat creep problems? Im using the hotend fan from the mini and I cannot print PLA longer than 10 Minutes and extruder starts to click. Im guessing it has to to with heat creap? The funny thing is that I dont get a glogged nozzle when it happens.

I did try out literally anything to get PLA printing again but extruder keeps clicking. Hotend fan not having enough power or defect stepper motor are my last options, atleast thats how Im feeling at the moment.

Best, Anxodia

Hi,

The stock hotend fan should be sufficient, you might have other issues in your system:

1. Check the fan orientation, it should push air to the heatsink.

2. I assume you bought a V6 hotend? If so, if it is a clone, maybe the heatbreak is not the best quality?

3. Check the extruder motor temperature, if it is too hot, it might transfer the heat to the filament. In that case you might try to reduce the motor current to keep it cooler. If it's cold, try to increase the current a bit (increase the power)

4. I assume other filaments work ok (PETG)? If not maybe you have something that blocks the path

5. Check extruder gears to be properly aligned and clean. Also check the extruder tension.

6. Is this a new filament? Maybe it has flow problems? I had some issues with eSun silk pla, it creates a lot of backpressure for me...

7. Make sure there are no gaps between thr nozzle and the heat break. Try dissasembling it and clean them all up. Maybe some old filament leaked somewhere/burned up and is blocking the path.

Good luck!

RE:

Hey Adrian, thanks for your reply.

1. Check the fan orientation, it should push air to the heatsink.

Checked it, its correct. I dont feel a lot of air coming out of the other side of the hotend though.. just a little bit. But then, its just an axial fan.. they are not too strong anyway.. I can definitely feel good amount of air when I hold the fan unmounted, but mounted theres not a lot of air comming out on the other side of the cooling fins from the hotend.

2. I assume you bought a V6 hotend? If so, if it is a clone, maybe the heatbreak is not the best quality?

Its an original one and I also did apply the thermal paste very carefully and made sure there is enough everywhere! I did NOT apply thermal paste inside the heater block or nozzle, only at the heatsink-heatbreak connection. I did dubble check that its also the 40W heater cartridge. I did replace thermistor and cartride that came with the hotend kit and tried the old parts from the mini hotend, still the same readings and still clicking and jamming.

3. Check the extruder motor temperature, if it is too hot, it might transfer the heat to the filament. In that case you might try to reduce the motor current to keep it cooler. If it's cold, try to increase the current a bit (increase the power)

Its about the same than X,Yor Z motors.

4. I assume other filaments work ok (PETG)? If not maybe you have something that blocks the path

First of all; I am only using Prusament Filaments. PETG works flawlessly but I only tried 0.2 layer height, nothing smaller. I also changed the nozzle to a fresh & clean one before trying to print PLA again. Also the inside of PTFE and heatbreak looks perfectly clean. I think I can print PLA at 0.2mm Layer but 0.1 or below gives me the clicking and jamming. I am using brand new Jet Black Prusament PLA which I got on monday and its a fresh batch from 04/2022.

5. Check extruder gears to be properly aligned and clean. Also check the extruder tension.

I did take apart the extruder atleast 3 times since having problems with PLA. I checked the gears they are aligned perfectly and the path is free. Also the Idler spins freely.

Tension is a bit harder one for me; I had it as the Prusa Manual states for the MK3s Models. But since its a Mini Bear Mod Im not sure if that still applies to this extruder now. I am using theese extruder parts : https://www.printables.com/model/57693-prusa-mini-direct-extruder-with-ir-sensor/files I think they are R6. It doesnt look like its grabbing too deep into the filament so maybe I could go a little tighter. But then, would the extruder really click if the tensions was on the lower side or would it just chew the filament?

6. Is this a new filament? Maybe it has flow problems? I had some issues with eSun silk pla, it creates a lot of backpressure for me...

As stated, its brand new Prusament PLA Jet Black. Printing at default Prusa settings. Tried to go up on the speed and without retraction but still jams and starts to click. I am using the "V2 Profile" for the slicer from this original post of the mod: https://www.printables.com/model/37939-prusa-mini-mk3s-bear-ultra-upgraded/files

7. Make sure there are no gaps between thr nozzle and the heat break. Try dissasembling it and clean them all up. Maybe some old filament leaked somewhere/burned up and is blocking the path.

No leaks, everything clean and a brand new E3D V6 nozzle. I have a small gap between nozzle and heater block, so the nozzle and heatbreak should have no gap. I tightened it with torgue wrench. Also the PTFE tube is pressed all the way down while pulling the collet thing up.

From Hotend and extruder side its should really not be the problem.

Things that I think could be the problem:

-Insufficient cooling from this mini hotend fan.

-Bad thermal paste that came with the original E3D V6 kit.

-Extruder Motor defect or running too hot (Altough its not hotter than X,Y or Z)

-Slower printing at lower layer height means more time spending closely above the heated bed and thats heating up the things?

-Ambient temperature too hot? Its no more than 28°C inside.

-Idler tension? This could be the one 4 sure. Would need a lot of testing..

-Bad unlucky filament spool? I had a 0.05mm 18 hour print last week when everything was working with Mystic Brown PLA that is around 1.5 years old.

Thanks for further advice

Best, Anxodia

RE: Prusa Bear Mini Mk3s

Hi Anxodia,

It does seem that you did your homework well :), sorry to hear you're still having problems 🙁

What I'd try next:

1. Try a different filament, maybe there's something wrong with the current one.

2. When you pull the filament out, after clicking, how does it look like? Does it look like it was melted/soft above the hotzone, into the heatbreak? This could mean heat-creap issues.

3. Do you have something to measure the extruder temp, or maybe the heatsink temp? PLA gets soft around 60C. If you get that temp before your hotzone, it can explain your issues.

4. If you're having issues only at smaller layer heights, maybe the extruder cannot handle that pressure? Not enough power? (Maybe increase current?) Although you said you printed other filament fine.

5. Try moving into a temperature controlled env, for a test print, where you have AC, see if it still happens.

For the extruder tension: you could look at the filament after clicking. You can check for damage, if it looks clean, just teeth marks, it should be fine. If it has grinding spots, the tension might be to low.

I should note that I'm a newbie myself, I might give you wrong info, sorry for that!

Unfortunately I don't have the same setup as you:( I'm using a Sherpa Mini extruder from when I modded the Mini to Direct Drive (without bear mod). It's a geared extruder with 50:8 ratio, so it should have a lot of torque, and because it has a plastic gear, it should not transfer the heat from the stepper to the filament and I recently switched to a Revo hotend because I didn't really like how the v6 nozzles need to be changed (hot tightning, specific torque) - because of this, I never changed a nozzle:)) (before Revo, that is).

I had no issues with this setup, but then again, your setup should be fine as well, try narrowing the problem (easier said than done tho..). I'd try to eliminate the heat creep first (or confirm it) by:

1. Using AC set to something like 20C (do not use an enclosure)

2. Use a hair drier on cold air to push air through the heatsink while printing, see if the issue still happens

3. You could monitor temps with thermal camera or IR thermometer if you have one handy - also check extruder temp

Best of luck!

RE: Prusa Bear Mini Mk3s

Hello Adrian

Do you think Sherpa mini can be done without buying new parts? If I just could print stuff and try decoupling the heat from the stepper I would try it. But Im probably missing a few parts.

Best, Anxodia

RE: Prusa Bear Mini Mk3s

I think you'll need to buy the mecanical parts + stepper (some of them you might already have), you can print the body yourself. There's a guide here: https://github.com/Annex-Engineering/Sherpa_Mini-Extruder. You can also buy the "official" extruder (with motor) by LDO for around 65€ (just google "ldo sherpa mini").

But unless you tired of trying / just want to get it working (+spend some extra money) I'd try to fix the curent setup as there is nothing wrong with the design, maybe just somethig faulty somewhere.

RE: Prusa Bear Mini Mk3s

Would it take long to change it so its works with the sherpa but with the E3D V6?

RE: Prusa Bear Mini Mk3s

I already replied to your previous question, but it's "awaiting moderation". See attached photo.

Would it take long to change it so its works with the sherpa but with the E3D V6?

since the original extruder uses E3D V6, it shouldn't be too difficult to just make a Sherpa mount, provided you have the step file for your extrduder. I think there are models availabe on Printables for Sherpa + V6.

RE: Prusa Bear Mini Mk3s

Look for "Sherpa Mini for BearEXXA" on Printables. I won't post the link as it seems every time I post a link, the post awaits moderation.

Remember to print it mirrored to preserve PINDA probe location.

RE: Prusa Bear Mini Mk3s

Thanks very much! So I did contact Prusa Support about this and was suprised they helped me even tho its a very modded Prusa mini.

I was over 2 hours in the chat and we did try many things. They also provided me with some GCODE to test print but they all failed. They also checked my Prusament Batch and told me that they have not had any other reports of bad PLA from that timespan.

Then I did some test on my own again. I tried printing at 200°C and 230°C and on both prints extruder started to click again and filament jammed.

Then I did unmount the Print Fan and mounted it with zip ties so it blew directly into the window where you can see the bondtech gears, to hopefully cool the gears in case they got hot by the motor. And it clicked again. I immediately opened the tensioner and touched the bondtech gears. They were not even warm. So thats not the problem then.

Further I tried increasing the first layer gap so it needs less pressure to push the filament out and also did run a Test with 97% flow in case the pressure was too big. That didnt solve it either. I might try it with extreme values like 90% flow to see what happens. Again, it clicks only at 0.1mm layer or lower. Not at 0.15 or 0.2mm.

I will take apart the hotend again and replace the thermal paste on the heatbreak with CPU thermal paste which is for sure more efficient than this white stuff that came with the E3D kit. I might aswell try to aim the print fan at the heasink in addition to the hotend fan and see what happens.

Theres really not much more left to test... I will try another filament at 0.07 layer height aswell just to be sure. And if nothing is helping, I guess I will order a pre-assembled hotend directly from Prusa and hook it up.

Thanks again for your efforts. You not only provide me with good iputs, but also motivate me to go further and find a solution. If I hadnt had anyone to talk about the issue and also write down what has been done already I would've stopped to chase the solution already. This is very much appreciated!

Best, Anxodia

RE: Prusa Bear Mini Mk3s

Hi,

Glad I could (try?! :)) ) to help, sorry I couldn't be more helpful. Very nice to hear Prusa is willing to help even though you modded the printer, that proves it worths to buy original (in addition to R&D efforts and better QA)

So, at least you know the stepper/extruder is fine, no overheating.

Hmm, I have an idea... I assume this happens on first layer? Maybe your z-offset is too big? Try decreasing it a bit (moving the nozzle up a bit, 0.05-0.1mm?) my logic being: if 0.15 works, but 0.1 doesn't, maybe you're 0.05mm to close to the build plate and there is no room to push the filament?. If it doesn't happen on first layer, it may not be a problem.

If you're going to replace the hotend, try something like a Revo, no more thermal paste, hot + two hand tightning, less things to worry about :). It's a bit more expensive though :(. They have a Revo V6 which they say is a drop-in replacement for e3d v6. If you get it, remember to increase your regular temps with 5-10C, the position of the thermistor is different and it reports 5-10C higher than regular V6.

Best of luck and please let us know the results/solution.

RE:

Hi, I finally solved the jamming issue.

I did try another color PLA also from Prusament and it printed without any problems. I then came a cross the term "hotend seasoning".

I did it and it prints now without jamming. I printed a small dust filter box. Then I cut some sponge, added 3 drops of avocado oil and put the sponge into the box. Filament then goes through the box and it gets lubed by the avocado oil. Seems a bit weird but if you read it up you will find out that it works for many people and also worked for me.

Heres a chart where the smoke points of kitchen oils are listed, in case anyone wants to try it: https://rubber3dprinting.com/3d-print-filament-lubrication/

And heres the dust filter box that I used: https://www.thingiverse.com/thing:153807/files

Best, Anxodia

RE: Prusa Bear Mini Mk3s

Awesome!

Glad you got it solved!

Happy printing!:)

Motedis Type B Profiles

Hi,

@firstlayer did you ver get around to modifying the parts to fit with the b type profiles?

RE: Prusa Bear Mini Mk3s

Hi all,

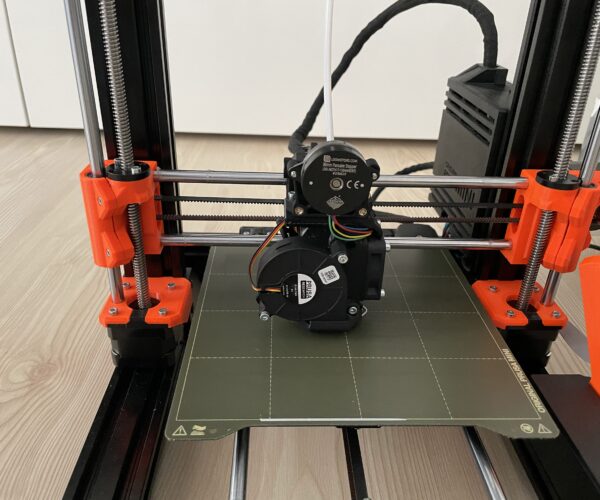

I really enjoy this mod, and have recently gotten my printer up and running.

However, I've run into some cable management issues. My extruder cable seems to be a bit on the short side, and I circumvented this by drilling a hole in the Buddy board case. I'm using the original Prusa MINI+ extruder stepper. My filament sensor cable is also way too short, so I just left it disconnected.

Does anyone have any elegant solutions to share, maybe?

RE: Prusa Bear Mini Mk3s

Hi,

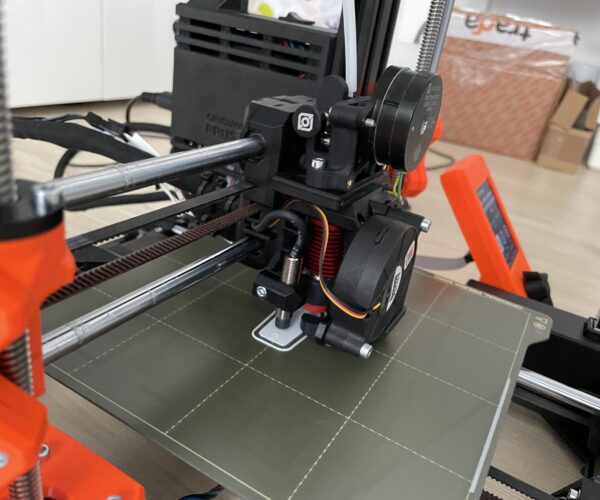

is the part "extruder_body" the once which need to be modified for the pinda probe to fit on this mod? I don't see that the parts have to be mirrored as a modification, since it can be done quite easily in the slicer. The way I've seen it with the makes, you actually want the Bear extruder because it has the right belt path. In the pictures you can clearly see that the belts do not run parallel to each other but converge towards the extruder.

Would love to hear your opinions on this.

RE: Prusa Bear Mini Mk3s

Hi all,

I really enjoy this mod, and have recently gotten my printer up and running.

However, I've run into some cable management issues. My extruder cable seems to be a bit on the short side, and I circumvented this by drilling a hole in the Buddy board case. I'm using the original Prusa MINI+ extruder stepper. My filament sensor cable is also way too short, so I just left it disconnected.

Does anyone have any elegant solutions to share, maybe?

Hi. You can buy the cable to the Mk3 and switch the connector to the Buddyboard with the OEM cable. On the stepperside cut the cable and soldered a extension if you don´t want to buy the Mk3 stepper. /Tomson

RE: Prusa Bear Mini Mk3s

Hi,

is the part "extruder_body" the once which need to be modified for the pinda probe to fit on this mod? I don't see that the parts have to be mirrored as a modification, since it can be done quite easily in the slicer. The way I've seen it with the makes, you actually want the Bear extruder because it has the right belt path. In the pictures you can clearly see that the belts do not run parallel to each other but converge towards the extruder.

Would love to hear your opinions on this.

Hi. I´m not shore which stl you referring to, mine and pear3D:s stl is mirrored. It was a long time ago i built mine and i later made the hurricane. But i think i change the beltpath alittle for the "freeside" to have more clearence on that model. You have right it´s not 100% parallel but i never have an issue with that. /Tomson