RE: Different Hotends

@clemens-m

see i hat grave extrusion problems, tried all the solutions going around, even upgraded to a bondtech heatbreak. nothing really seemed to give me more than 2 hours of solid printing until the extruder started clicking again due to some clot in the hotend. i'll tinker some more, learning my ways around that machine but if all else fails, i'll try and upgrade to a different hotend.

I found that even the bondtech heatbreak suffered the same PTFE tube shrinking. I ended up taking my PTFE tube from the Mini and cutting it to a bit of length longer than the bondtech one and using that with the bondtech heatbreak. Quite honestly I could have probably just gotten a longer PTFE tube on the stock heatbreak and it would have worked I am guessing. I beleve that this problem will come back again, and even faster after long prints >2hrs .

RE: Different Hotends

@kevman

jeah, that's my fear also. i guess, we'll see in a bit. i'll print one of the mounts for a v6 hotend to be prepared if it fails too often 🙂

RE: Different Hotends

Here’s also E3D v6 hotend mount on MINI:

https://www.prusaprinters.org/prints/28046-prusa-mini-v6-conversion-upgrade

It does not look overly complicated.

RE: Different Hotends

...aaand Mosquito too.

https://www.thingiverse.com/thing:4201537

but you may need to figure screws yourself.

RE: Different Hotends

@crawlerin

Thanks, i still have to wait for a new heater block to even print a mount for a new hotend 😁

RE: Different Hotends

@strandedbandit

That's a very Chicken and Egg problem if I have ever seen one 😀 Hope you get it soon and have it repaired.

RE: Different Hotends

@strandedbandit

in your case a second printer would be helpful. i3 repairs mini and vice versa mini repairs i3. This resolves the chicken egg problem 😋

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Different Hotends

@karl-herbert

Which, I believe, makes the i3 the chicken, and the Mini the egg. 🙂

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: Different Hotends

Sadly my Coop is too small for a whole Flock of chickens (as usual taking taking the metaphor too far) 😀

I guess after waiting almost half a year for the mini, i can go at least two weaks without a hotend.

This whole experience is very Charakter building. I feel zen. 😀

RE: Different Hotends

@jasii

almost 2 weeks now 😀 are you still satisfied with the copperhead on a mini? and in case one was to buy said copperhead. one should go for a reprap heatsink and heatbreak, right?

best regards.

edit: and furthermore: do the heating cartrige and thermistor of the mini fit in the copperhead heaterblock just like that?

RE: Different Hotends

@strandedbandit

The copperhead is very nice. No jams but time will tell.

--------------------

Chuck H

3D Printer Review Blog

RE: Different Hotends

@strandedbandit

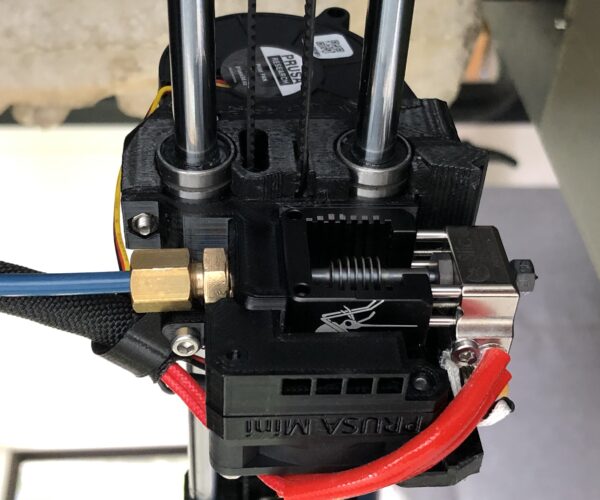

Yes, I am satisfied. I took my Copperhead/Mini mount apart this weekend to check for any mounting part melt areas. None were found.

The Copperhead configuration can get a bit confusing. Here's what I know:

- If you want to use either of the Copperhead Heat Sinks then only the Copperhead 'Standard' heat break is compatible

- The 'RepRap 1.75' heat break is designed to screw into the existing E3D V6 heat sink

- I used the Groove Mount heat sink because the Screw Mount was not available yet

- I am waiting for Screw Mount to design Mini mount but think I would go with Groove Mount (same price - MKx compatible)

- I used the existing heat cartridge and thermistor, no issues (other than trying to get them out of the Prusa heat block!)

- If possible, go with the single Bowden tube design by adding passthru festo on extruder

On my mount design, I am debating making a different, simplier, mount that has the Copperhead in 'normal' orientation with airflow left to right. This, however, would require an added gcode command to reset home, -Y axis, in the slicer after bed leveling, before print. If you forget, the priming bead prints in air! That might be a frustrating issue.

Any more questions, or opinions, let me know.

Jerry.

P.S. - to reinforce, from Slice Engineering website:

PLEASE NOTE: The Copperhead™ Heat Sink is only compatible with the Copperhead™ Standard Heat Break because our Copperhead™ Heat Sink uses a shank and collar mechanism (no threading) to hold onto the heat break.

Ref: https://www.sliceengineering.com/products/copperhead%E2%84%A2

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: Different Hotends

@strandedbandit

Yes, I am satisfied. I took my Copperhead/Mini mount apart this weekend to check for any mounting part melt areas. None were found.

The Copperhead configuration can get a bit confusing. Here's what I know:

- If you want to use either of the Copperhead Heat Sinks then only the Copperhead 'Standard' heat break is compatible

- The 'RepRap 1.75' heat break is designed to screw into the existing E3D V6 heat sink

- I used the Groove Mount heat sink because the Screw Mount was not available yet

- I am waiting for Screw Mount to design Mini mount but think I would go with Groove Mount (same price - MKx compatible)

- I used the existing heat cartridge and thermistor, no issues (other than trying to get them out of the Prusa heat block!)

- If possible, go with the single Bowden tube design by adding passthru festo on extruder

On my mount design, I am debating making a different, simplier, mount that has the Copperhead in 'normal' orientation with airflow left to right. This, however, would require an added gcode command to reset home, -Y axis, in the slicer after bed leveling, before print. If you forget, the priming bead prints in air! That might be a frustrating issue.

Any more questions, or opinions, let me know.

Jerry.

P.S. - to reinforce, from Slice Engineering website:

PLEASE NOTE: The Copperhead™ Heat Sink is only compatible with the Copperhead™ Standard Heat Break because our Copperhead™ Heat Sink uses a shank and collar mechanism (no threading) to hold onto the heat break.

Ref: https://www.sliceengineering.com/products/copperhead%E2%84%A2

Thank you for posting this. I am thinking about diving down this path, I hate that I can't make the Mini work out of the box, but this might be a good solution. Where did you get the pasthrough festo? I am a bit new to this hobby so it might be a basic question that I am uninformed on.

RE: Different Hotends

@jasii

great. That's a very helpful post! Thanks so much for this. I'll follow your updates closely, should you be inclined to keep us posted :).

Eventually I'll upgrade either to a Copperhead or a Mosquito, going for a V6 just seems like an unnecessary intermediate step. If I'm to invest that much into that little machine I'll probably go for the Bondtech extruder update, too.

RE: Different Hotends

@kevman

"Thank you for posting this... Where did you get the pasthrough festo?"

I am in the US so I found them on Amazon. As happens, the title is accurate (M10) but the description is wrong (Thread: 6mm). The Mini extruder is M8 so I made an adapter (M10-M8) which I will post along with the mount sometime this week. (Son is flying in from Czech today so busy week ahead)

https://www.amazon.com/gp/product/B01IB81IHG/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

Note: I had use for the 10 (MMU2 upgrade on MKx). I do not know if there are smaller quantities out there. Just make sure it is a 'passthru' not just a 'straight fit', for 4mm OD tube.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: Different Hotends

@jeffrey-l15

Very good idea and well done 👍 !

Would you like to publish it in prints?

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Different Hotends

@jeffrey-l15

Very good idea and well done 👍 !

Would you like to publish it in prints?

I am working on finalizing the pieces. I do plan to publish them.

RE: Different Hotends

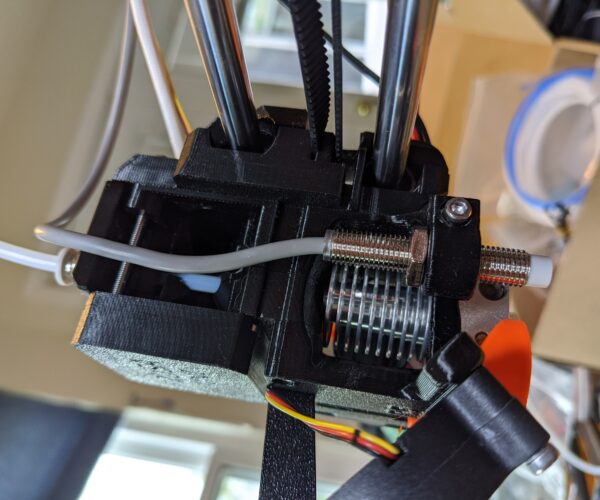

Totally overkill but completely worth it. I've been running this setup for a short while, around 50hrs or so print time. Printing mostly with PETG at the moment. It has been performing flawlessly for me so far. Bye bye heat creep.

RE: Different Hotends

@woraphot

Looks very nice. What mount did you use?

Thanks,

Fred