Bowden tube won't stay in push-connect fitting

So I picked up the Bondtech extruder/heatbreak combo and installed them and while I was at it put in a single bowden tube setup. Everything was working well with PETG but when I switched over to PLA major problems. I tried most of the suggestions in the post on extrusion issues and decided to go back to the stock heatbreak. That's when I started having problems with the bowden tube.

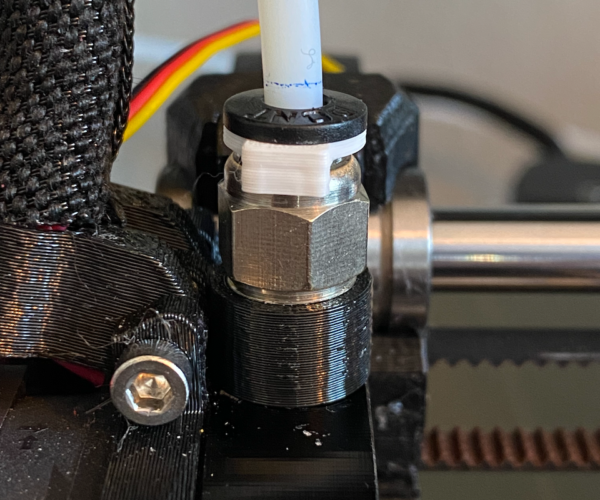

As you can see in the attached picture it doesn't want to stay down when I start printing (the initial Z calibration from the onboard menu), it doesn't have an issue with purging.

I've tried two different connectors, a drilled out PC4-M8 and a PC4-M10 with adapter and two different bowden tubes, basic PTFE and a Capricorn one. Anyone have any ideas?

MINI+ with FW:4.3.3, Bondtech IFS Extruder, drilled out PC4-M8 couplers, 1 piece Capricorn bowden.

RE: Fixed it

Wow! 120 degree chamfer is important, I pulled my ptfe out and recut the chamfer and took off a bit more than previously, reinserted and everything is working now.

MINI+ with FW:4.3.3, Bondtech IFS Extruder, drilled out PC4-M8 couplers, 1 piece Capricorn bowden.

Great to hear you made it work. I was originally going to suggest that it may not be the chamfer because I use PC4-M8 connectors on my minis but never bothered to put a chamfer on the Bowden tube. Works fine. But then it occurred to me that i never dared to drill out the connectors, so I still have the small piece of PTFE inside the hotend, which does indeed have a chamfer.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

No chamfer

No chamfer for me. Straight from extruder right into hotend down to bottom of heatbreak. Works fine.