Bondtech Heatbreak any good?

Hi all,

I've had an awesome time with the mini as my first printer - when it works. However, like many on this forum, I keep getting stuck on the hotend / extruder clogging issue. I've tried quite a few fixes, like moving the heatbreak up into the heatsink, increasing the printing temperature, or replacing the ptfe tube only for it to shrink a few hours later and leave me with a clogged hotend.

To that end, I was wondering how effective the Bondtech heatbreak is. I've seen lots of posts mentioning it, yet never found a definitive answer. For those who have it, how was the install process and what adjustments did you need to make to gcode, firmware, etc? Most importantly, did it solve your hotend / extruder clogging issues?

Thanks!

RE: Bondtech Heatbreak any good?

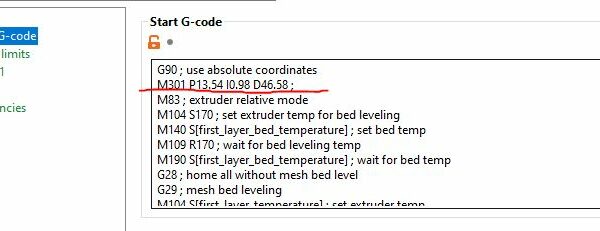

I installed it without any issues, my main issue was under-extrusion and the strong preference for Prusament filament to make a long story short It solved my main issues got a workable printer now that even prints 2.5 year old filament. The Manual on there website explains it all only one thing to do is to change the start GCODE (There M301 gcode was not enough for me so I did the procedure my self (I have a sock) aand have some different M301 values) your mileage may vary. I did not had/have any clogging issues...

Stock MK4S with FW 6.2.6

RE: Bondtech Heatbreak any good?

After a few dozen hours my Mini started clogging and had the expanded end on the filament problem where the filament was sneaking around the end of the hot end PTFE tube and the filament could not retract. (I think the tube gets hot and shrinks)

I changed out the stock heatbreak for the Bondtech (including their shorter tube) and installed a Bondtech Dual Extruder (I want to do flex filaments later). I’m not sure which one fixed the problem but together it has been printing without clogging during multiple 12-15 hour prints with both Prusament and non-Prusa PLA. The Bondtech heatbreak is the design Prusa should have used.

RE: Bondtech Heatbreak any good?

Thanks so much for your responses. I decided to go for it and the heatbreak is on its way. I'm looking forward to installing it and will update as I go!

RE: Bondtech Heatbreak any good?

@classic

This thread is amazing and I was going to start one myself if I have t found it. Thank you for that. Everyone talks about the heartbreak upgrade and the bondtech extruder upgrade but no one really shared what their long term experience is. I got the printer a week ago and it started doing the clicking but no underextrusions yet at least on most of the prints. I’m on the fence of ordering the upgrade kit. Was wonder what is your experience with it on the long term and how long have you been using. Did it fix your issue and did the extruder or the heatbreak improve your prints. I’m fairly new to 3D printing and was curious how difficult of an install would it be for a newbie like me. Thank you again.

RE: Bondtech Heatbreak any good?

How about 6 weeks and multiple 7 to 9 hour prints?

Since making the changes I would not say that it has “improved” the quality of the prints, but it has made the printer utterly dependable. The prints didn’t have any issues before and they don’t have any now.

However, now I feel comfortable watching to be sure the first layer goes down correctly (the live Z must be correctly set) and letting the printer run overnight.

Until the warranty on the Mini expires and I can break out that tab on the motherboard and flash the necessary alterations to the firmware, I have to put the different PID numbers and Bondtech Extruder specific numbers in the slicer’s “Custom G-Code”, but it is only a minor issue and only when using some else’s already sliced G-code - something I do only occasionally and with great caution.

I would do the mods again in a heartbeat.

RE: Bondtech Heatbreak any good?

@vazovsky

Thanks for the feedback. I ordered the upgrades and I’m looking forward to install them. Like you said I don’t have any issues other than the annoying clicking sound and the prints are great quality with the stock parts. But if it makes it more reliable I’m all for it. Does the upgrades void the warranty. I know breaking the board does which I’m not planning on doing anytime soon but don’t know if the upgraded fall under that too or not. Thanks

RE: Bondtech Heatbreak any good?

I forgot to mention, I also replaced both the Mini’s Bowden tube and the Bondtech’s internal HDPE tube with Capricorn Tubing. I don’t trust the OEM tubings’ temperature ratings and figured as long as things were apart, I might as well put in the higher temp rated tubing in case I ever wanted to try ASA. If you don’t plan on doing that, you probably would not need it.

RE: Bondtech Heatbreak any good?

@mohamed-fashni

I think the fact that I forgot about this thread because I haven't needed anymore help is a good sign...

The Bondtech Heartbreak absolutely fixed the clogging / under extrusion issues on my Mini. Two months, lots of printing hours and a decent amount of long prints later, I don't think that issue has ever come up.

In terms of installation, I was a little intimidated at first being a beginner myself, but nothing is too complicated. However, let me offer a bit of advice...

1. When unscrewing the nozzle, set the temperature to 290, shut off the machine and then release the tension in the nozzle. I found that if I left the printer on, the temperature would drop (because my wrenches acted like a heatsink) and it would try to compensate by pumping in more electricity. I don't know if there is anything wrong with this, but it unnerved me, so I did it that way (which Prusa chat recommended).

2. I'm not proud of this one, but I'll tell you in the hopes you won't repeat my mistake. Make Sure You Are Unscrewing The Nozzle The Right Way!!!!! When unscrewing the nozzle from above, as I was, the unscrewing directions are reversed. I truly thought I was breaking the machine until I realized what was happening. Please make sure you take this into account, and don't laugh at me too hard...

3. I managed to strip the grub screw holding the thermistor cartridge in place (I couldn't tell you how), so watch out for that.

4. Same thing with the three grub screws on the side of the hotend, they strip easily, so be careful with them.

When I was finished with the installation, I had some pretty massive stringing going on, so I toyed with the retraction settings until it became manageable. Make sure retraction isn't too high, however, because that will cause your hot end to clog as well. I hope this helps. Happy printing!

RE: Bondtech Heatbreak any good?

@classic

Thanks for sharing this. Glad I saw this before I started the process of changing out mine. Like you were, I am feeling a bit intimidated by the process.

Also what happens if you need to replace the tube? I noticed they have one with a chamfered end on one side. I guess I could probably fashion one myself if I really had to replace it.

RE: Bondtech Heatbreak any good?

@classic

Thanks for the great feedback and advice. The bond tech extruder and heartbreak came in today and I will be installing soon or as soon as the stock one fails. It currently has no under extrusion and a little clicking but not affecting the print quality. I will definitely take your experience into consideration when I’m installing it. I have a question about the Prusa warranty. My mini is less than a month old and to my understanding there’s a one year warranty on it expect for the pei sheet. If I upgraded the mini now would that void the warranty on it . Thank again

RE: Bondtech Heatbreak any good?

Well

I had different experience with bondtech heatbreak - it sure fixed the clogging issue but created a more serious one at the same time.

Jamming and inconsistent extrusion . I didn't managed to fix it , you could see it clearly when printing parts with supports , you could see a small "lagging" where for a few mm the nozzle was not extruding and then making a small blop of filament.

After weeks of trying and talking with support - I replaced the heatbreak with original one and just ordered a proper length (43.3mm) PTFE tube from the shop, In fact I ordered 3 of them to be sure. After this I don't have any problems at all, no clogging or inconsistent extrusions.

RE: Bondtech Heatbreak any good?

@classic

Thanks for sharing this. Glad I saw this before I started the process of changing out mine. Like you were, I am feeling a bit intimidated by the process.

Also what happens if you need to replace the tube? I noticed they have one with a chamfered end on one side. I guess I could probably fashion one myself if I really had to replace it.

I have had my Bondtech for about four months now, and the tube hasn't shrunk. I think the main point of it's design is the tube doesn't get as warm so there should be no need to replace it. If you ever do, the two you get with the Mini should be easy to just cut down to the same size as they are longer and share the same chamfer.

It fixed my issues, any other issues I've had have always been the nozzle being too close to the bed (this can even vary by filament brands and type for me), extruder idler being too tight or too loose, or first layer adhesion.

RE: Bondtech Heatbreak any good?

There are printable fixtures on Thingiverse to cut the tubing the correct length and chamfer angle. However, it works great with the softer (less expensive lower temperature) HDPE tubing, but they won’t cut the chamfer in the harder Capricorn tubing. I just ended up sanding the chamfer and had no problems.

RE: Bondtech Heatbreak any good?

@nerolit

I had a similar problem, try loosening the top grub a little when using the Bondtech. I think it was pinching the filament in the PTFE ever so slightly and causing extrusion issues.

RE: Bondtech Heatbreak any good?

and ensure that you still have a 2mm passage on both ends of the PTFE tube (use the rear end of a 2mm drill bit) when you have used too much pressure/force while tightening the couplers the inner part deforms...

Stock MK4S with FW 6.2.6

RE: Bondtech Heatbreak any good?

Well , as I said - the problem is no more since I used correct lenght PTFE - zero jams and clogging since May.

RE: Bondtech Heatbreak any good?

There are printable fixtures on Thingiverse to cut the tubing the correct length and chamfer angle. However, it works great with the softer (less expensive lower temperature) HDPE tubing, but they won’t cut the chamfer in the harder Capricorn tubing. I just ended up sanding the chamfer and had no problems.

Which Capricorn tubing did you use? When looking at their shop site I could not decide which one is right.

RE: Bondtech Heatbreak any good?

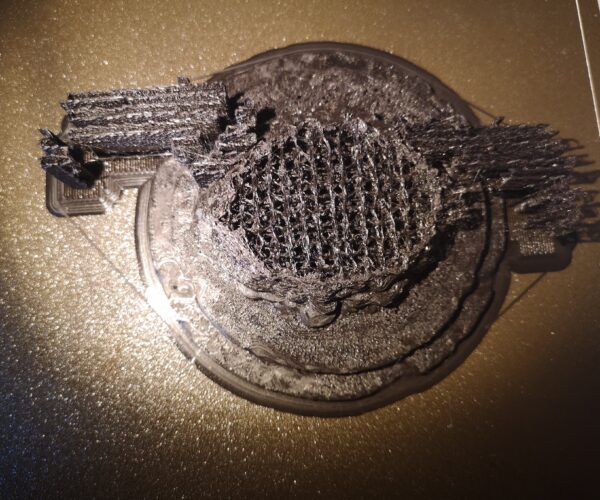

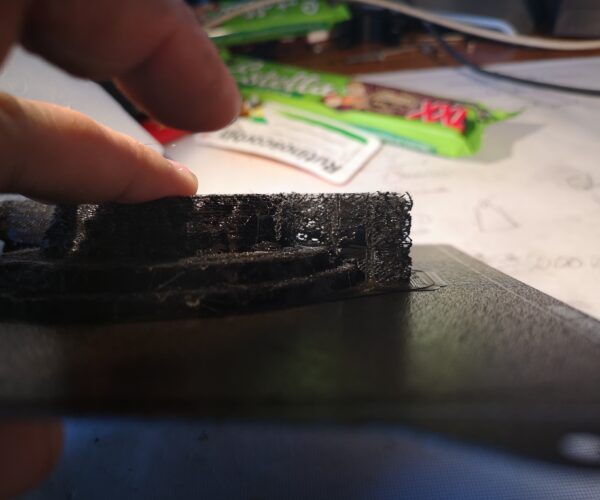

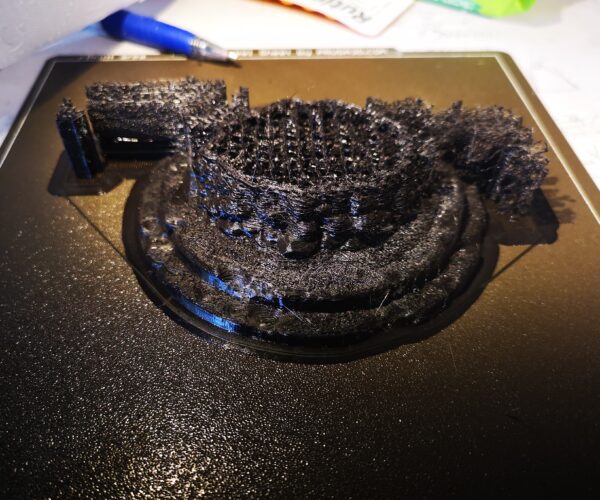

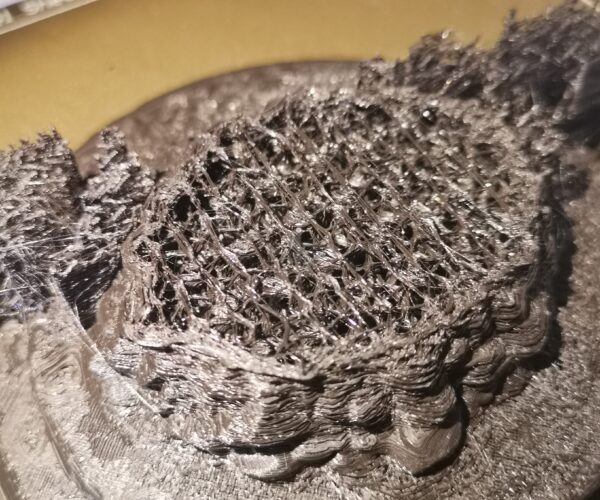

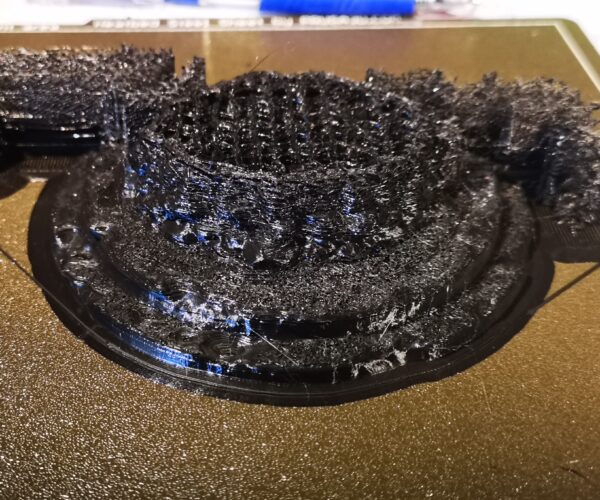

I gave a heatbreak another chance when replacing the nozzle - it printed simple things without problems, cali cubes etc.

But when I started printing normal model...you see the results. What is wrong? I used normal profile from prusa, with PID inserted into starting G-code.

Profile: 0.10mm detail, filament is Fiberlogy PLA on built in prusa profile for that filament.

RE: Bondtech Heatbreak any good?

@japu

Sorry, but I did not see your question. It is probably too late for you now but for future readers I used the higher temperature, more expensive blue tubing.

It is still going strong without major issues I did have a minor half clog (Some filament still came out) so I did a cold pull and that fixed it.

I think this was caused by a very cheap roll of filament and/or letting the filament sit in the extruder at temperature after a print finished while I was answering some emails. Since then I have been careful to unload the filament when I am finished and have not had a reoccurrence of the partial clog.

This has all been with PLA. Next up is some PETG