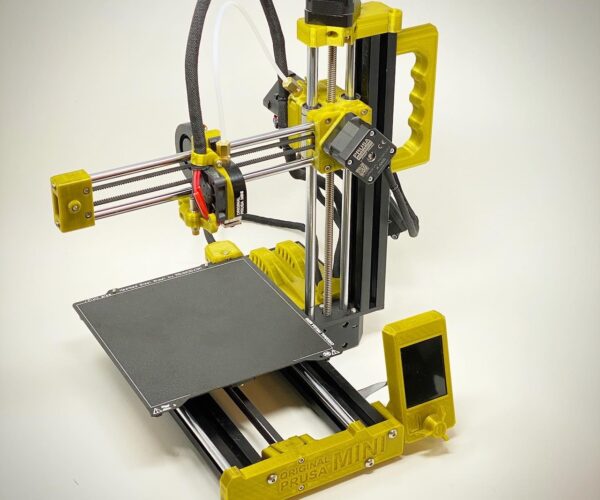

All parts reprinted - works better overall

I reprinted all of the plastic parts using Prusament PETG yellow gold (I purchased this roll thinking it would be more golden, but it's more of a sparkle puke yellow so I thought I'd put it to good use here). For the most part, the Prusa factory-printed parts are okay, but not the best. After totally disassembling and replacing all the plastic parts (mostly - the one part I did not replace yet is the bottom of the electronics box) I have found that the printer is quieter overall. Specifically, the extruder gears no longer click incessantly during retraction.

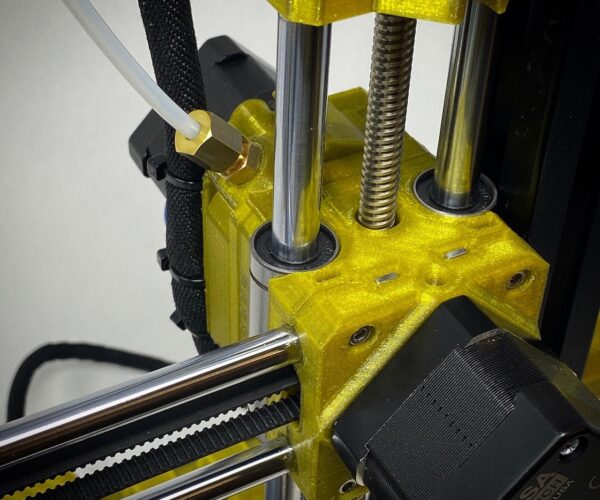

Since there doesn't seem to be a complete assembly guide anywhere I just sort of winged it. Some notes: the X and Z axis bearings are now held in place with plastic parts surrounding the bearing rather than using zip ties to do the job; on the X axis idler, there seems to be some sort of tension adjustment with the 2 side screws but since they only thread into plastic without any nuts, I don't see how they can do much adjusting (did they forget to include the hole for the square nuts?)

Anyway, if you have the time and desire, I would recommend the switch. It gave me a much better understanding of how all the parts work.

RE: All parts reprinted - works better overall

Looks really cool. What printer did you use to print them?

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: All parts reprinted - works better overall

@geoper2

I used the mini shown in the photos to print its own parts.

RE: All parts reprinted - works better overall

could you please share the settings you used for printing the parts (print settings, infill, other settings you have adjusted)

Stock MK4S with FW 6.2.6

RE: All parts reprinted - works better overall

I reprinted all of the plastic parts using Prusament PETG yellow gold (I purchased this roll thinking it would be more golden, but it's more of a sparkle puke yellow so I thought I'd put it to good use here).

LOL. Yeah, "Yellow Gold" is a bit misleading - maybe thay should rename it "Golden Shower" 😉 But nice work. Are there specific parts in particular that you think contributed the most to the increase in performance?

RE: All parts reprinted - works better overall

could you please share the settings you used for printing the parts (print settings, infill, other settings you have adjusted)

Sure, I used Prusament PETG Yellow Gold, used the standard Prusament PETG MINI profile, 0.20mm SPEED MINI and changed to 3 perimeters and 40% grid infill. Printed on a scotchbrite-scrubbed textured plate. All parts were default orientation except for one, which I turned on side for better strength and used supports.

RE: All parts reprinted - works better overall

I reprinted all of the plastic parts using Prusament PETG yellow gold (I purchased this roll thinking it would be more golden, but it's more of a sparkle puke yellow so I thought I'd put it to good use here).

LOL. Yeah, "Yellow Gold" is a bit misleading - maybe thay should rename it "Golden Shower" 😉 But nice work. Are there specific parts in particular that you think contributed the most to the increase in performance?

Yes, definitely all of the extruder parts made a difference. I no longer have any audible clicking when retracting. It was fairly straightforward reassembly, parts like bearings are pressed into place and you have to reassemble in a certain order. I think the entire extruder assembly could use an upgrade and anticipate Prusa making significant changes to the printed parts here, perhaps as an "s" upgrade that has some small parts and a set of customer-printed parts. Also, the x axis idler part doesn't seem to have a functional tensioner. The screws on the side don't do anything.

RE: All parts reprinted - works better overall

I don't recommend that handle, however. It puts a lot of stress on the weakest connection. On my mini, that part is easily skewed, throwing the X and Z axes out of alignment.

Pete

RE: All parts reprinted - works better overall

Looks great, nice job!

RE: All parts reprinted - works better overall

can you please tell me how to replace the X end stop

Stock MK4S with FW 6.2.6

RE: All parts reprinted - works better overall

@pete-b3

I don't have a Mini (and with the waiting list, probably never will) but there appears to be an issue with the vertical member being out of square with the frame. I wonder is it would be possible to brace and adjust the "squareness", by adding a member (with some small adjustment) going from the top of the vertical element (Z motor mount) to the frame. It could incorporate a handle. Obviously the overall height would increase because it need to clear the cable bundle going from the extruder to the Z carriage. Again not sure of the mini geometry but perhaps the filament spool could be mounted on it.

RE: All parts reprinted - works better overall

@pete-b3

I don't have a Mini (and with the waiting list, probably never will) but there appears to be an issue with the vertical member being out of square with the frame. I wonder is it would be possible to brace and adjust the "squareness", by adding a member (with some small adjustment) going from the top of the vertical element (Z motor mount) to the frame. It could incorporate a handle. Obviously the overall height would increase because it need to clear the cable bundle going from the extruder to the Z carriage. Again not sure of the mini geometry but perhaps the filament spool could be mounted on it.

This is something I'm working on with the extrusions and parts I have kicking around here right now. Just don't have a concrete design yet. I had real skew and alignment issues when I first assembled the printer, requiring a bunch of shimming work. But I know it is still easily moved or thrown out if stressed.

But, again, I don't recommend lifting the printer from that arm. My recommendation is to lift only from a piece of MDF or plywood that is under the printer and in contact with all five rubber feet.

Pete

RE: All parts reprinted - works better overall

@pete-b3

I guess if you could make the additional sufficiently rigid, there's no reason not to attach a handle and spool but of course that would be optional. I suspect the most difficult problems are a. clearing the cable bundle and b. attaching robustly to the base. I wonder if it would be possible to project a beam fore and aft from the z motor mount, to clear any possible movement of extruder assembly, the two beams to fore and aft opposite corners of the base. It would allow adjustment of z assembly in two plains. Overkill?

Alternately, bolt the mini to a rigid base (sheet steel?) then add adjustable bracing on the three open sides of the z assembly. Increased footprint is minimal but a weight and perhaps sympathetic vibration penalty.

RE: All parts reprinted - works better overall

@pete-b3

Okay I’ll be careful

RE: All parts reprinted - works better overall

can you please tell me how to replace the X end stop

The x idler part will only be released once the x motor is removed, which puts enough slack on the belt that the idler bearing slips out and then you can remove the x idler part. Removing the x motor requires many steps.

RE: All parts reprinted - works better overall

[...]

Thank you, For now the part F1 X End stop is back in service. dismanteling the printer at this moment is not something I want to do -- I'll move the replacement to the 'After Coronna todo list' 🙂

Stock MK4S with FW 6.2.6

RE: All parts reprinted - works better overall

@pete-b3

I guess if you could make the additional sufficiently rigid, there's no reason not to attach a handle and spool but of course that would be optional. I suspect the most difficult problems are a. clearing the cable bundle and b. attaching robustly to the base. I wonder if it would be possible to project a beam fore and aft from the z motor mount, to clear any possible movement of extruder assembly, the two beams to fore and aft opposite corners of the base. It would allow adjustment of z assembly in two plains. Overkill?

Alternately, bolt the mini to a rigid base (sheet steel?) then add adjustable bracing on the three open sides of the z assembly. Increased footprint is minimal but a weight and perhaps sympathetic vibration penalty.

The way I'm looking at doing it is to have two 8030 extrusions under the y axis, attached to the extrusions there, and then tie in the Z / X riser on its outside face. Then the whole thing is bolted to the MDF base (which has rubber feet) and no longer sits on the pads it came with. I don't have anything elegant yet, though 😛

I also don't want to invest $300 in a $350 printer, so trying to keep it reasonable and with stuff on-hand.

Pete

RE: All parts reprinted - works better overall

@pete-b3

I guess if you could make the additional sufficiently rigid, there's no reason not to attach a handle and spool but of course that would be optional. I suspect the most difficult problems are a. clearing the cable bundle and b. attaching robustly to the base. I wonder if it would be possible to project a beam fore and aft from the z motor mount, to clear any possible movement of extruder assembly, the two beams to fore and aft opposite corners of the base. It would allow adjustment of z assembly in two plains. Overkill?

Alternately, bolt the mini to a rigid base (sheet steel?) then add adjustable bracing on the three open sides of the z assembly. Increased footprint is minimal but a weight and perhaps sympathetic vibration penalty.

The way I'm looking at doing it is to have two 8030 extrusions under the y axis, attached to the extrusions there, and then tie in the Z / X riser on its outside face. Then the whole thing is bolted to the MDF base (which has rubber feet) and no longer sits on the pads it came with. I don't have anything elegant yet, though 😛

I also don't want to invest $300 in a $350 printer, so trying to keep it reasonable and with stuff on-hand.

Pete

RE: All parts reprinted - works better overall

How long did the tear down and rebuild take you, respectively? Awesome work!

Be bold. Be brave. Be better.