Heating the Prusa enclosure

Hi,

i am considering to get myself a Prusa enclosure. I am looking for a way to monitor and influence the temperature in the enclosure. I read on the Prusa site that this feature is being worked on. How did you guys solve this already?

My current setup (Ikea lack) is in my garage where the temperatures in late fall to early spring, are too low for the printer to even start ("Temp error"). I cannot move the printer to a warmer environment, so i am looking for a way to heat the enclosure.

I have been looking for solutions (transform an egg incubator, perhaps a heatmat for a terrarium, a carheater(i think too dangerous because of my plastic enclosure windows) etc).

Did any of you solve this problem for your enclosure?

Bart

RE: Heating the Prusa enclosure

I have never needed to do so even when my shop is 0 degrees C.

--------------------

Chuck H

3D Printer Review Blog

RE: Heating the Prusa enclosure

I have never needed to do so even when my shop is 0 degrees C.

In the article on the subject it states that the Min Temp (Bed) error for my printer (MK3S) starts at 10 degrees celcius. My printer protests like it is supposed to. That's why i need heat: the temp error blocks operation.

RE: Heating the Prusa enclosure

Hi JSW,

thank you for sharing! That is looking very well!! What kind of display are you using?

Is the fan equipped with a heating element? Or is it used to blow in air from the room in wich the enclosure is situated?

My enclosure is in a room that as a temp <10 degrees celcius; so that would not be an option for me...

I fear that using a car heater( fan with heating element) will prove to be too much (plastic melts etc). So i am looking for someone who has dealt with this problem...

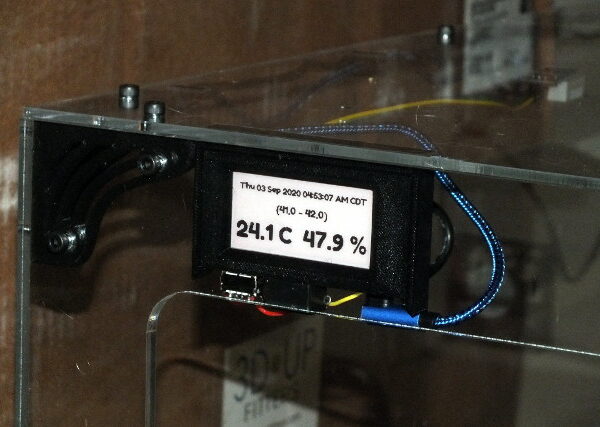

Not the Prusa enclosure, but I use a Raspberry Pi Zero and a junk box temp/humid sensor to monitor, and it is set up to control the fan, but I seldom use that feature at all.

RE: Heating the Prusa enclosure

The display would be the Inky Phat from Pimoroni. I happened to have one on hand when I put the thing together. The frame is the front part of a case from another project using the Pi Zero and the Phat.

It's the always-on paper-white type of display.

https://shop.pimoroni.com/products/inky-phat

There is a similar newer display from Waveshare which is about the same size as well.

When I started out, I intended to have a fully closed-loop system, with the Pi turning the fan on and off to hold the temp between two control points. That did not work as well as expected in real life, even though the initial tests with a heat gun were successful. The fan in the enclosure (3d Upfitters) is not strong enough to significantly lower the temperature below the high control point in many cases, and to put in a more powerful fan would obviously increase the turbulent (and even laminar) flow in the enclosure, which I do not want.

I now use it only as a monitor, even though it will hold the fan off at print start-up until the lower control point is reached.

The improvement of ABS prints was significant when I added the enclosure, so I am leaving things as is for now.

RE: Heating the Prusa enclosure

What a great idea! Have you thought of the option to open the doors (eg by MG90s or a lineair actuator) slighty to let heat escape?

That is one side of my Enclosure problem (coloing down in the summer). Now the heating still remains...

RE: Heating the Prusa enclosure

I haven't done it , but was wondering about it earlier and watched this video.

Might be an option to look at.

RE: Heating the Prusa enclosure

When I started out, I intended to have a fully closed-loop system, with the Pi turning the fan on and off to hold the temp between two control points. That did not work as well as expected in real life, even though the initial tests with a heat gun were successful. The fan in the enclosure (3d Upfitters) is not strong enough to significantly lower the temperature below the high control point in many cases, and to put in a more powerful fan would obviously increase the turbulent (and even laminar) flow in the enclosure, which I do not want.

I had the same experience. I never found fans to be useful and in fact, they are often harmful to print quality.

--------------------

Chuck H

3D Printer Review Blog

RE: Heating the Prusa enclosure

Wouldn't this kind of heat be too much/too agressive? The carheater will send heat inside of (i think-don't know) about 60-70 degrees celcius. That could hurt the plastics on my printer and in my enclosure. I'ld rather have a heatsource i can manage. A heatsource i could tell to only send heat of (say) 21 degrees. Not max heat(eg 60-70 degrees celcius) to heat up a room as fast as possible.

Or am i too cautious and would this carheaterconstruction work perfectly?

I haven't done it , but was wondering about it earlier and watched this video.

Might be an option to look at.

RE: Heating the Prusa enclosure

My impression is that the temperature consistency and the lack of turbulent airflow is more important for successful ABS/ASA prints than the value of the air temperature in and of itself.

Before I got the enclosure, I found the draft shield option to be quite effective.

RE: Heating the Prusa enclosure

In my Voron I do have a tiny bit of airflow (don't know how turbulent it is, it is just there to apply a very weak underpressure to keep fumes in, not to move much air) but enclosure temperatures are at 50-60°C. ABS prints wonderfully in there, even if I ramp up the part cooling fan.

I think the closer you get to 90°C in the enclosure the more you can do whatever you like and get great ABS prints with good layer adhesion and basically no warping. 50°C is already a good start too and that temperature is much more achievable than 90°C for sure. If the enclosure is rather around 25-35°C however, a draft shield will be most likely very useful as well as keeping part cooling to an absolut minimum.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Heating the Prusa enclosure

So if i understand correct: the closer the temp gets to 90 degrees celcius, a draft will become less of a problem?

In my Voron I do have a tiny bit of airflow (don't know how turbulent it is, it is just there to apply a very weak underpressure to keep fumes in, not to move much air) but enclosure temperatures are at 50-60°C. ABS prints wonderfully in there, even if I ramp up the part cooling fan.

I think the closer you get to 90°C in the enclosure the more you can do whatever you like and get great ABS prints with good layer adhesion and basically no warping. 50°C is already a good start too and that temperature is much more achievable than 90°C for sure. If the enclosure is rather around 25-35°C however, a draft shield will be most likely very useful as well as keeping part cooling to an absolut minimum.

RE: Heating the Prusa enclosure

You do not need to get to 90C. Quality is great at 40 C.

So if i understand correct: the closer the temp gets to 90 degrees celcius, a draft will become less of a problem?

In my Voron I do have a tiny bit of airflow (don't know how turbulent it is, it is just there to apply a very weak underpressure to keep fumes in, not to move much air) but enclosure temperatures are at 50-60°C. ABS prints wonderfully in there, even if I ramp up the part cooling fan.

I think the closer you get to 90°C in the enclosure the more you can do whatever you like and get great ABS prints with good layer adhesion and basically no warping. 50°C is already a good start too and that temperature is much more achievable than 90°C for sure. If the enclosure is rather around 25-35°C however, a draft shield will be most likely very useful as well as keeping part cooling to an absolut minimum.

--------------------

Chuck H

3D Printer Review Blog

RE:

90°C is basically not feasible with a Prusa. It is what industrial grade FDM printers specialized for ABS are doing. At that temperature you also don't need a heated bed anymore. This in turn creates a very homogoneous temperature environment and also abolishes heat bed related warping too.

It is not necessary for reasonably sized high quality ABS prints to operate at such high temperatures however. I don't know what the minimum enclosure temp is where you start to get consistently good results. IMHO it is a gradient where things consistantly improve. I myself have experience with 50-60°C and there it works already very well. Already at 50° air movement isn't such a big deal anymore and one can in fact use quite a bit of part cooling harming layer adhesion significantly, at 90°C drafts would not matter at all.

I am pretty sure that at 40°C one can print ABS quite decently already as well, as cwbullet mentioned but I personally would be more careful there with part cooling then.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Heating the Prusa enclosure

I have found that consistent bed temp, limiting drafts, and temps at 35-40C are sufficient to limit warping and maximize quality with ABS, PC, PC Blend, ASA, and Nylon. I also tend to give my print bed a light spray with hair spray (Aquanet).

--------------------

Chuck H

3D Printer Review Blog

RE: Heating the Prusa enclosure

I think the stepper motors would also be operating well outside their spec at 90C, at that kind of temp you would need to start use water cooling. There is youtube where someone runs there cabinet at 100C

more insane than the 100C internal temp of the cab, the cab is made out of wood and I do not see any form of fire protection !!!

Still a good watch

90°C is basically not feasible with a Prusa. It is what industrial grade FDM printers specialized for ABS are doing. At that temperature you also don't need a heated bed anymore. This in turn creates a very homogoneous temperature environment and also abolishes heat bed related warping too.

It is not necessary for reasonably sized high quality ABS prints to operate at such high temperatures however. I don't know what the minimum enclosure temp is where you start to get consistently good results. IMHO it is a gradient where things consistantly improve. I myself have experience with 50-60°C and there it works already very well. Already at 50° air movement isn't such a big deal anymore and one can in fact use quite a bit of part cooling harming layer adhesion significantly, at 90°C drafts would not matter at all.

I am pretty sure that at 40°C one can print ABS quite decently already as well, as cwbullet mentioned but I personally would be more careful there with part cooling then.

RE:

Well, water cooling might be necessary but at 90°C you will also start to get problems with commonly used plastic parts in the long run and you'd also need other types of lubricant too.

I think a regular bed slinger at such enclosure temperatures is just not a very good design. Which is why printers usually try to isolate the 90°C to the very print area and even move the upper part of the print head out of the hot zone already. Take the Zortrax Inventure for example (one of the few somewhat affordable 3d printers with heated chamber), it is has a pretty small print volume but is one of the few somewhat affordable 3d printers with not only heated chamber (up to 80°C) but also a dual extruder designed for soluble supports as well. Its build chamber is completely isolated, only the heating block and the nozzle stick into it.

I can't stand that guy from that youtube channel, he was airing all sorts of crazy talk during Covid. Doesn't surprise me he would heat up a wooden enclosure to 100°C. You can actually run into problems with overheating stepper motors well below 90°C. It also depends on the current they are run at and the insulation rating. Some motors I know only have a rating of 130°C, others at 180°C. I shorted already once one of the former category at enclosure temperatures of 60°C, running them at the upper end but still within specifications in regard to running current.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Heating the Prusa enclosure

I can't stand that guy from that youtube channel, he was airing all sorts of crazy talk during Covid. Doesn't surprise me he would heat up a wooden enclosure to 100°C.

Yeah he's kind of a tool.

RE: Heating the Prusa enclosure

Hi Guys,

if found This study that states it could be safe to heat wood up to 100 degrees celcius. Other studies support 76 degrees celsius to be safe. I think i will use the 76 degrees to be on the safe side of the studies 🙂

I finally went with this solution of heating. I added a thermal fuse that works up to 76 degrees. As you all state in this post, that is more than sufficient.

Thank you all!