Dry Box feeding, how I did it.

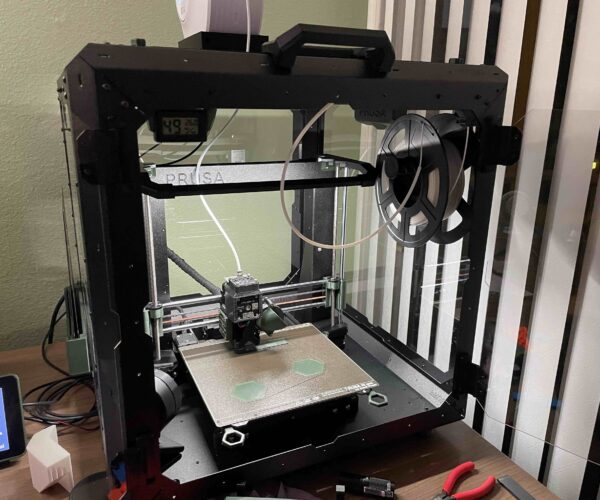

I live in a high humidity area so I generally print PETG from a Sunlu S2 filament dryer, just wanted to share how I did it to help others.

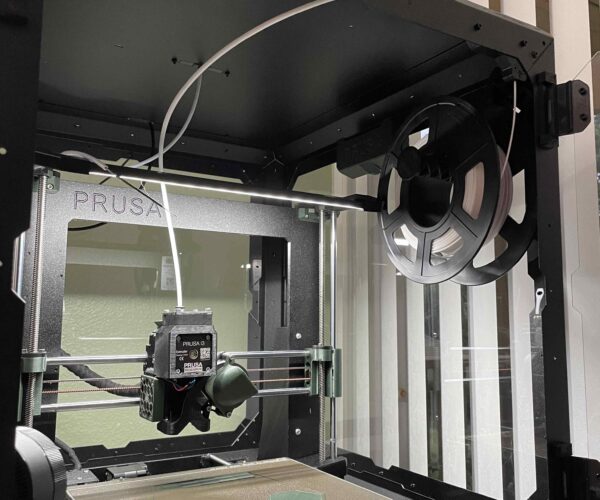

I had been using this magnetic reverse bowden before I had the enclosure so I reused it. I've read about loading complaints with the enclosure included parts so I just reused this. https://www.printables.com/model/108656-magnetic-reverse-bowden-adapter-mk3s

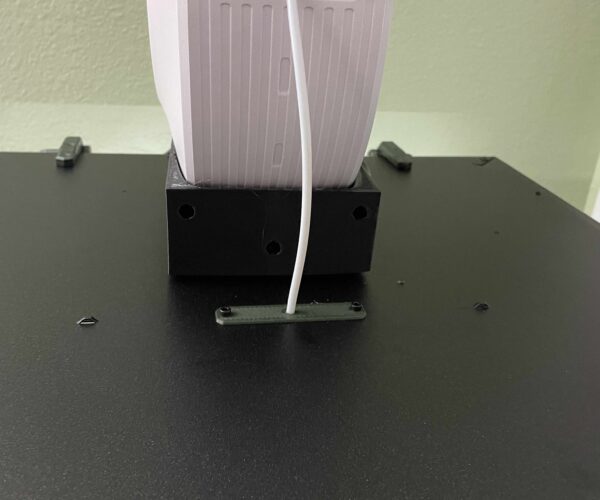

Sunlu wedge bowden feed https://www.printables.com/model/219366-sunlu-filadryer-s2-improvement-wedge

I used this pass through for the PFTE tube from the dryer to the extruder. I didn't bother to design a wider opening, I drilled it out with a 3/16" drill bit and pushed the tube through.

https://www.printables.com/model/276463-original-prusa-enclosure-filament-passthrough

This setup allows me to feet from the dry box, if I print PLA I plan to use the inside spool and included bowden. When I want to do that I just take the top magnetic bowden part and put it on the Prusa enclosure bowden tube.

Hope this helps someone.

RE: Dry Box feeding, how I did it.

Thanks for sharing. I might do a similar design for the other filament dryers I own. Thanks for sharing.

--------------------

Chuck H

3D Printer Review Blog

RE: Dry Box feeding, how I did it.

My printer has the same dual light bars as yours. Thanks for posting photos of it inside the enclosure. I'd been wondering it it fits!

RE: Dry Box feeding, how I did it.

I want to do something similar, but somehow I don't like the idea of having to swap the bowdens. Has anybody ever tried achieving something similar using some kind of a Y splitter right before the extruder?