Support Interface layer stuck

Hi,

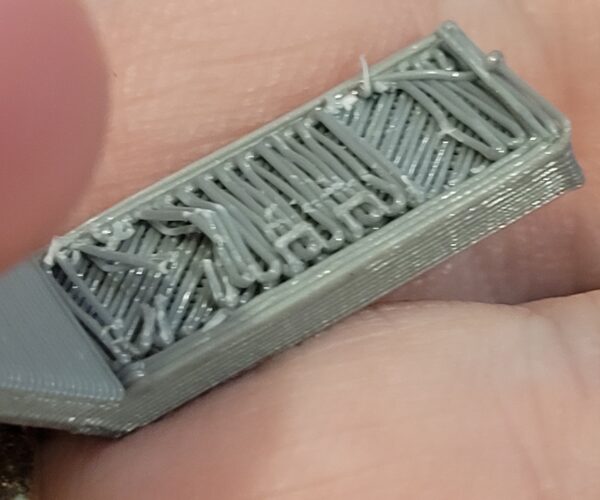

When printing with support I noticed that the last layer of the support get connected with the part and is almost impossible to remove.

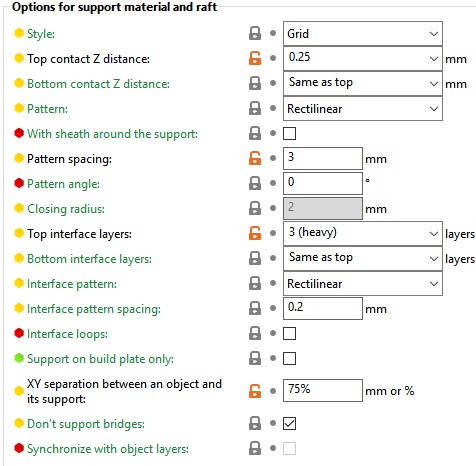

I tried several different settings, all with same results. These are my current settings:

Any suggestions?

Best Answer by Neophyl:

Hate to tell you this but I don't think it is the interface layer, I think that IS the bottom layer of your part that you are trying to scrape off. I'm guessing you are still using the thick bridges option.

Basically the layer printed above support is classed as a bridge. The default option is the old thick bridges which means the layer is nozzle diameter thick (not the same as your layer thickness) so probably 0.4mm in this case. That makes a thick chunky bottom. Because of the gap between the part and the support interface that bottom bridging layer isn't pressed down and squished. If it was then it wouldn't release from the support easily. However you can get left with a surface just like you have pictured.

Try turning thick bridges OFF and even reducing your gap to 0.2. Having a thicker interface layer can also make it easier to remove (I usually set mine to 4 or even 5 layers) as it then tends to come off in one go rather than breaking up.

RE: Support Interface layer stuck

Hate to tell you this but I don't think it is the interface layer, I think that IS the bottom layer of your part that you are trying to scrape off. I'm guessing you are still using the thick bridges option.

Basically the layer printed above support is classed as a bridge. The default option is the old thick bridges which means the layer is nozzle diameter thick (not the same as your layer thickness) so probably 0.4mm in this case. That makes a thick chunky bottom. Because of the gap between the part and the support interface that bottom bridging layer isn't pressed down and squished. If it was then it wouldn't release from the support easily. However you can get left with a surface just like you have pictured.

Try turning thick bridges OFF and even reducing your gap to 0.2. Having a thicker interface layer can also make it easier to remove (I usually set mine to 4 or even 5 layers) as it then tends to come off in one go rather than breaking up.

RE: Support Interface layer stuck

There seems to be a tendency to want to increase the Z distance on the top of the support from the default .2mm for break-away supports, and I do agree that in some cases it can have the effect opposite from what is intended, as the print layers above the supports may droop and sag into the support, as opposed to being lightly supported.

I have yet to see break-away supports that leave true visually-appealing lower surfaces above them.

RE: Support Interface layer stuck

It's the nature of the beast unless you can use a different material for the support that doesn't bind to your main material. Your settings should be okay to get the supports off for a decent but not great look. I for one much prefer Snug, not Grid supports for most models. More often than not I find the bottom interface to come off more reluctantly than the top.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Support Interface layer stuck

Thick Bridges did the trick. Not perfect but significant better! 🙂

Thanks

RE: Support Interface layer stuck

Support is a area that Cura is still way ahead of others IMO. Same print using Cura default settings get the easiest to remove support with almost no visible marks.

RE: Support Interface layer stuck

Would you mind posting a project file with that part in ? I'd like to experiment and see what I can get it like. Personal challenge 🙂

RE: Support Interface layer stuck

Sure, here you go. Support_Test

Let me know what you got 🙂

RE:

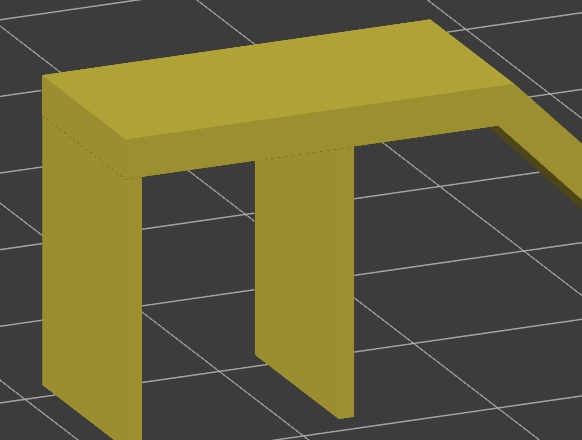

So this model is purely to test support settings (otherwise you obviously wouldn't print it in this orientation)? I didn't look at the support settings because @neophyl claimed it as homework 🙂 Just one other idea: If you have long overhangs like in this test model, you may consider putting some sacrificial support at the end and maybe in the middle and let bridging do the rest. I don't think it would be any worse than full supports.

Just a mockup to illustrate what I mean, in no way optimized:

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Support Interface layer stuck

It all started with an actual part that I printed and support was really bad. It was incredibly hard to separate both bottom and top and left a poor quality finish on the part, so I started printing this test to understand better the settings and how I could optimize them.

In case you want to see the real deal, this is the part I'm actually trying to print: tool box

RE:

Had a little time after work so I printed out the test part. Project should be attached. Been using Snug supports since they came out as they are much better but hadn't really changed any of my support settings from when I used Grid. One thing I had noticed though was that snug supports came off even easier than grid. So I tried the part with 0.2 contact z (my default), 0.15 and 0.1.

The filament was rPLA, some of the recycled stuff from 3dJake. Which actually prints pretty good normally and I had some left around. My Mk3 is fitted with a Nozzle-X so I normally print filaments a bit hotter which is why the project temps are more than you would expect. I get minimal stringing at 230 with PLA and these parts had none.

The following is the bottom surfaces at those contact distances.

For 0.2 the support block just came off very easily as expected. You can see it next to the part. The 0.15 also came away clean, and while it was a little more difficult to remove, id say it was about the same as grid at 0.2. Lastly the part with 0.1mm z contact. You don't see the support for that one as it was destroyed removing it. As expected it was pretty difficult to remove and took me a good 5 minutes to clean off just that small area. So wont be using that again. Ah well all in the name of science 😉

The bottoms have had no cleanup for the 0.2 and 0.15 parts, just a bit of a scrape with a fingernail for loose filament strands. The 0.1 has had a good scraping with a dental pick to get the interface layer off but has not otherwise been sanded or anything. Visually there isn't much if any difference between 0.2 and 0.15 but the 0.15 does feel slightly smoother to the touch. Not anywhere near actual smooth of course, just smooth-er.

Not pictured are the curved sections but both of those also released easily and I'd say the 0.15 looks a tad better. Both used the projects 0.25mm xy separation.