RE: Suggestions for improvements - PrusaSlicer

As I pointed out back near the start of this thread the correct place to make requests is on Github. The forum is great for thrashing out the details for making a good detailed request but the actual requesting is not effective here.

For example your angled support suggestion has already been requested https://github.com/prusa3d/PrusaSlicer/issues/7123 or a slightly different version https://github.com/prusa3d/PrusaSlicer/issues/4128

RE:

I think the title of this thread is suggestions for improvements: PrusaSlicer. Well, that's a suggestion. If the user's suggestions are answered by saying that they have to be done on Github or to show alternative forms through other tools, then I don't know what the point of this thread is.

As I pointed out back near the start of this thread the correct place to make requests is on Github. The forum is great for thrashing out the details for making a good detailed request but the actual requesting is not effective here.

For example your angled support suggestion has already been requested https://github.com/prusa3d/PrusaSlicer/issues/7123 or a slightly different version https://github.com/prusa3d/PrusaSlicer/issues/4128

Sorry for my poor English. I try to do my best.

RE: Suggestions for improvements - PrusaSlicer

Correct, the thread is pretty pointless. People keep making suggestions here and it’s not the place to do it or effective. Until Prusa allocate staff time monitoring for such (which they do occasionally when they specifically request feedback such as the 8 bit software thread in the general forum) then it’s wasted effort. This is why we point out the correct place and means.

By all means keep posting to the forum but adding your voice to an existing issue on GitHub is far more effective as they are tracked and given issue numbers.

RE: Suggestions for improvements - PrusaSlicer

yes, I know that there are alternative ways to what I ask. But it is not about that, this thread is to suggest improvements or additions to the program. That's what I do, that I don't need to use another program, export what I did with that other program and finally work with PS. I would prefer that in a simple way, the PS itself would allow what I suggest.

I know an easy way to do exactly that in PrusaSlicer, I have posted it in at least two other threads here. it also saves material and time.

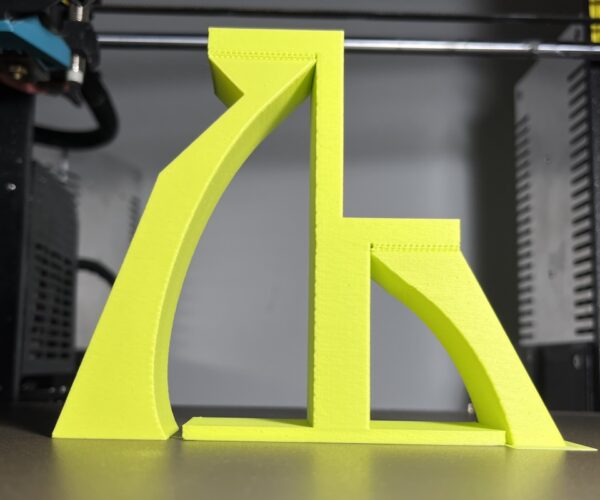

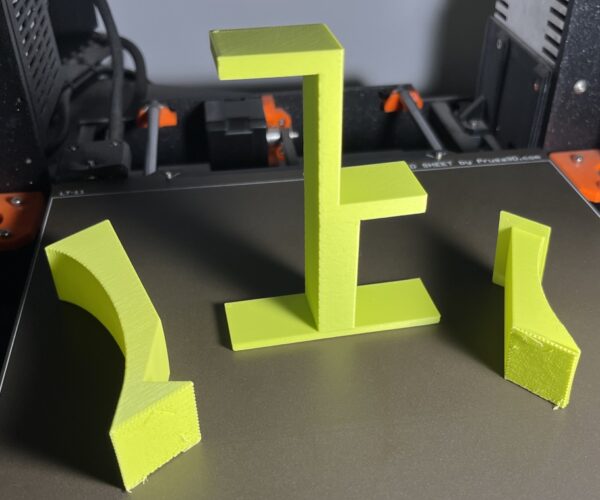

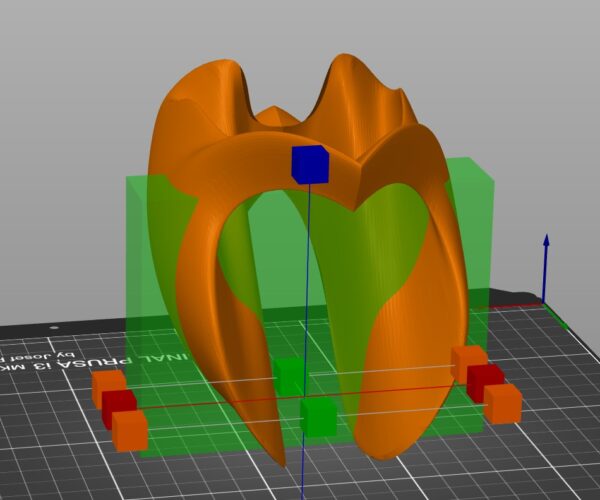

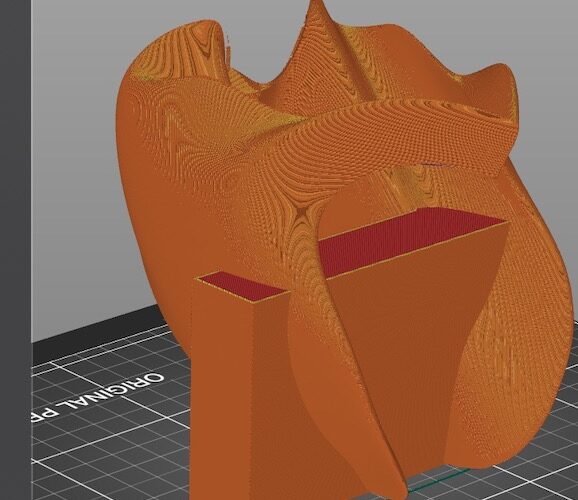

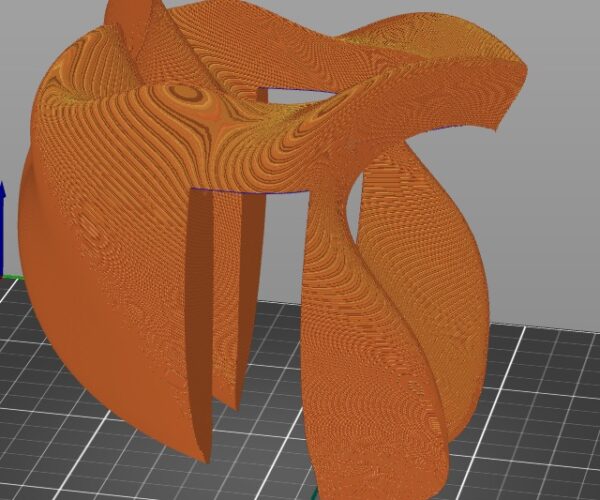

This took 15 min to create 100% in PrusaSlicer the model and the supports, this would have takin me 5 min to do in my 3D program, but I decided to do this one using Negative volumes and two modifiers in PrusaSlicer for those that don't use a 3D program. I highly recommend learning one. Regardless this took a total 15 min I sliced it 3 different ways to compare.

The two modifiers were used to make the supports 1 perimeter 2bottom and 3 top layers with no infill, That's it. and you can copy and paste that if you create the style for the modifier, that way you won't have to build it twice. I covered that in a previous thread as well, In that same thread I covered the copying and pasting of different types of modifiers.

1. The base model no supports, 2hours 37min 22.30 g

2. the base model with default supports set to Snug, 3hours 31min 41.59 g

and finally the one in the images shown, 3hours 10min 30.42 grams

it prints faster with less material and the supports are more stable then trying to use the defaults.

Default supports applied in between parts. Just enough to create the breakaway.

Certainly if you wanted the support structures could be reduce much more for even more time and material savings, this was a supper quick example and it still added up.

good luck

Swiss_Cheese

The Filament Whisperer

RE: Suggestions for improvements - PrusaSlicer

As I said in a previous post, what I was suggesting was that it would be nice if PrusaSlicer incorporated it directly as an option and not look for alternative methods based on the user's creativity.

Despite the above, I thank you @swiss_cheese (and also, of course, @jsw and @towlerg) for the ideas you provide. And @swiss_cheese thank you for the effort to reproduce the figure, you have been very kind.

Sorry for my poor English. I try to do my best.

RE: Suggestions for improvements - PrusaSlicer

Hello,

I like Prusaslicer, thank you for all your work on developing and making it better,

I would like to give my wish:

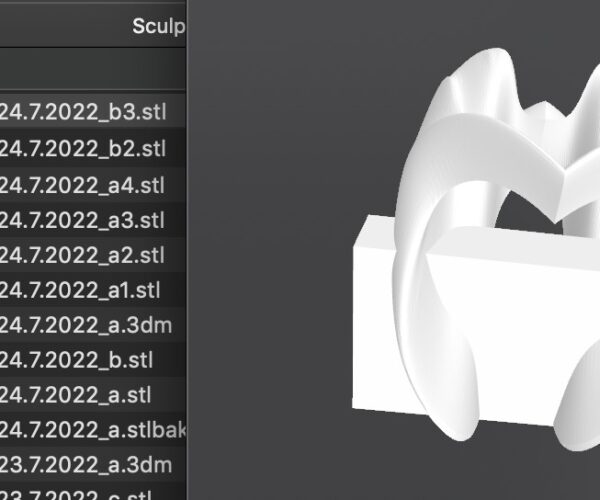

Because I'm doing sculptur and we need sometime to take away material,

in the export stl function, the soft consider adding a cube but not subtracting a cube,

the subtraction is working for printing but not when exporting the new

sculptur stl, do you think it will be possible to add this functionality.

Thanks in advance

Marc

Export as stl for sculptur with negative geometric form, thank you in advance

if it's possible

RE:

Please tell me if there is and if there is no such possibility to add it, the fact is that it is very necessary to change the value of the flow of the first layer for relief tables, since the plastic goes into the holes of the relief and flow adjustment is required. Thank you.

RE: Suggestions for improvements - PrusaSlicer

Automatic generation of geometry that improves the ability to assemble and glue parts, when cutting a part.

It is a pain to make a file, just to realize it is going to be too big for the build plate. adding the geometry in the CAD program add other comblications.

I Suggest that the slicer would be able to suggest or help make geometry, eg holes and pins, on the surface used to cut the the part in two. the holes and pins would allow the part to be easily alligned for gluing.

the process could be as follow:

Choose cut part > select "add tabs and holes" > pick placement or auto generate placement.

You should be able to select type of geometry, similar to how infill is selected (Round, square, sqaure with rouned corners, slots, ellipsical, puzzle piece etc) as well as the dimensions of the geometry. As well as the offset of the geometry eg how much bigger should the hole be than the tab/pin. thios could be compared to how the elephants foot compensation works.

Best regards, Simon

RE: Suggestions for improvements - PrusaSlicer

That some people complains that people further make suggestions here rather on the githhub is maybe a question to the dev. why the hell is it so complicated to make a suggestion.... you have again to register... I have an account for all my prusa things... so why not using this oe as well to be able to feed the suggestion box....Maybe that way not so many suggestion can be made...minimizing effort and maybe getting away from very good idea... I am sure I am not the only one thining this who had two or three suggestions for the dev... Maybe the admin of the forum could also bring the suggestion into the github...at the occasion not more than once a month will be like a good periodicity... it will be great.

my suggestion: I used the trick mentioned by jeff 3d corner to get sla tree support. it would be nice to have a lightning feature like support instead of the grid or snug version. Or If you know a way to get that.: embedding your model in a bigger box and having the lighting function...I do not know...

Best Regards

frog frog.

RE: Suggestions for improvements - PrusaSlicer

I´m sure folks will happily add some to their pile of unpaid work to save you the extraordinary hassle to register on Github.

Twhy the hell is it so complicated to make a suggestion.... you have again to register.

..(...). Maybe the admin of the forum could also bring the suggestion into the github.

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE: Suggestions for improvements - PrusaSlicer

@justme3d

I´m sure folks will happily add some to their pile of unpaid work to save you the extraordinary hassle to register on Github.

It's not unpaid. The Prusa Development team is paid. They are employed by the Prusa company. I think your confusing Prusaslicer with some other GitHub projects.

As well, other projects on GitHub are also "funded" meaning not being developed for free. Open source does not mean free to develop. Blender is also a wonderful example of this.

As for Prusa they pour $$$ into PrusaSlicers development, and GitHub for this project is a pain in the ass, there should be an easier way to make a suggestion. If you post a suggestion here, at least you get the benefit of having other more knowledgeable users see it, and they might even be able to show you that you can already do the thing you were wanting to suggest, you can't get that on GitHub,<-- Not often anyway.

RE: Suggestions for improvements - PrusaSlicer

Sure being paid... I am doing stuff during my free time and give it to the open source community. so I give of my freetime.it is not money but time is money... sorry but I cannot agreee with you. I have published more than 70 models

So when I see that kind of answer I must say I am disappointed. the other problem of the gitthub is I do not know what I have to choose to make a request....

So saving me the hassle is only getting the idea of others not into your suggestion box...So this is quite sad.... When I see that all chinese company that steel the idea of others.... so ideas and suggestion may be the money of tomorrow.

RE:

@Vitting:I must be absolutely agree with you. I will as well wish the possibility to select the shape of the connectors in order to make snap fit as well!! but the idea is very good.I had the same idea... however I think a good way would be to have a webapp doing that...

the same with the tree support....

why not having prusaslicer as a webapp? Best Regards

RE: Suggestions for improvements - PrusaSlicer

@dr_froggy_rd

Maybe English is not your first language, but you might want to take a bit longer and work on it. your words are difficult to understand. This has the effect of making your point seem less valid.

Just a suggestion.

RE: Suggestions for improvements - PrusaSlicer

The problem I have now is that you ae discrediting my post by saying it is very difficult for you to read my post which sadly is not a very kind strategy you would have done that in a pm it would have been better... So I will try to do better...so what? now that I wrote=> I react toward your post somehow in the same way as you???

I believe this is not the point.

I believe discrediting the other party is a way to put a stop on this discussion. which is sad.

My point was

A)I think it could be anybody that may publish our points from the forum into the githhub in order to make a feedback read by the dev that are not looking to other source of feedback... Which is a way to make their life easier. in a way due to have to much to do... you know maybe that a lot of retired people are involved in opensource project... So they have paid their contribution to the society already but decide to do it anyway...thanks to them. or the other people that invest some of their freetime to give to the community like you do as well If your not prusa employee...

B) again about the suggestion of vitting>>>doing a stl partitioning in a cad software like Freecad is not quite user friendly (as about the GitHub point==People are less prone to give a feedback there as on the forum).

if this could be achieved in PSlicer this could be very neat. I also thought of that with snap fit feature as well... instead of the proposed nipple and holes adjustment geometries as connectors between two cut parts. some work around do exist but those are not automated...you may not place the things at the right position because you are human. which results in several printing attempts...

C) I would have welcome a ligthning infill like support strategy... I made a piece half of it in weight was support so i used the trick proposed by jeff 3d corner using the sls profile and exporting the plate including the support...maybe someone achieved this with the ligthning infill?

Has anybody achieved to export the stl plate including the infill this would be great?

I can save the .3mf format but this cannot be read by otherslicer or I lay wrong?

D) you can add a property "support material" with interface and pattern not exactly like in the print setting submenu: where I expect to see grid and snug...

I do not know what would be the difference there. I see a honeycomb support option when I use this kind of modifier I see indeed a honeycomb support. why not having here the lightning infill as well...so one can have the 3D-honeycomb Infill or the gyroid as support structure as well. and the possibility to export plate including the support as stl for this as well? It does exist otherwise for the sls printer I do not get why it is not extended to the standard printers...

Best Regards

Frog Frog.

@dr_froggy_rd

PrusaSlicer is not a CAD or design program, it is a slicer, already it is doing many things that are better addressed in the original CAD. If you want precise supports they should be part of the original design, that way they are slicer independent.

A slicer cannot guess your intentions so anything more than rudimentary support is going to tie your design to a particular slicer and diminish your flexibility.

Has anybody achieved to export the stl plate including the infill this would be great?

Again, infill can be designed into the original part as required, if a particular arrangement is needed for internal support then this is the best way to go. It then becomes part of the original file, it's easier with step but doable with stl if required. The slicer's generic support option remains available when it's not critical.

I can save the .3mf format but this cannot be read by otherslicer or I lay wrong?

.3mf can contain settings for multiple slicers, all slicers do not have the same features so only those settings that your slicer understands will be used but a diligent designer can provide alternatives for many within the same container file.

It does exist otherwise for the sls printer I do not get why it is not extended to the standard printers

The sls technology requires different support and infill techniques, in particular it is important that uncured resin can easily drain out of the structure. Solutions for different methodologies are necessarily different.

Suggestions and bug reports have a designated procedure which appears to work. The moderators on here are not paid so expecting them to relay messages is unreasonable.

@vitting

Adding keyways and splitting is another task that is better done in the original design software, perhaps as a parametric option. It's quite easy to do in Prusa Slicer with modifiers but again it ties the design to the slicer.

Cheerio,

RE:

It's quite easy to do in Prusa Slicer with modifiers but again it ties the design to the slicer.

@Diem Hi, I'm curious, say I wanted to split a large object and add a blind ended keyway to glue the parts together. I use the cut function having rotated the object appropriately then add the male part of the keyway and using negative space form the female part. How do I align the two keyway parts so the the original object can be correctly assembled?

RE: Suggestions for improvements - PrusaSlicer

You place the negative space modifiers, like a cylinder or cube before cutting the part. When the part is cut and the 2 are rotated such that the cut ends are placed to the bed the modifiers are duplicated for both so the position for them is kept.

@towlerg

Yes, @neophyl has the method. To clarify: it's easiest to make and cut a void to leave space for a seperately printed key.

Cheerio,

RE: Suggestions for improvements - PrusaSlicer

Thanks guys. I see the point of using negative space on both half's but it would be great to know how to align a positive and a negative addon component.