Strange toolpath render for edge

Dear all,

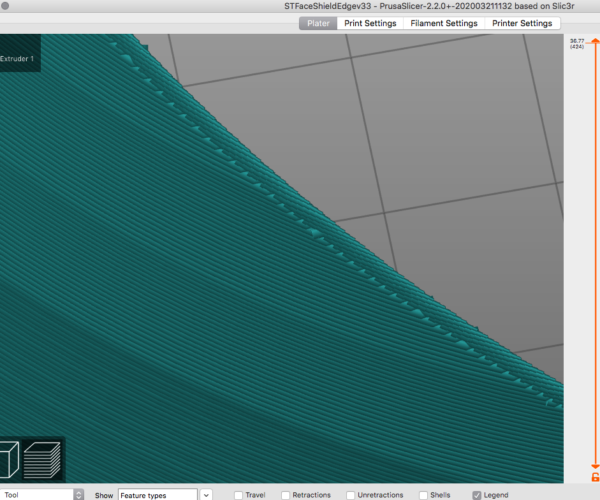

I'm struggling with a "shield" print. The design is of my own, so I can also alter the original model if that would help, but for now I do not understand why prusaslicer, which I otherwise find excellent, is trying to print the edge separately from the rest of the perimeters:

Thank you for your time,

Edmunds

Best Answer by Neophyl:

@sprudzs-edmunds

Turn off detect thin walls. That is what is causing your issue with the edge of the shield. With your over wide extrusion widths of 0.8mm it cant print them as the edges are too thin but with detect thin walls on it tries to print that thin edge anyway. As its then gets processed different you get the separate printing action. When turned off it prints as you want.

Your extrusion widths combined with your infill pattern are also why you aren't filling in the bottom. Your first layer extrusion width of 0.6 is whats limiting the fill. If you drop it to 0.45 you will see that it tries to fill in more of the area. Unfortunately that effects the perimeters too as they are all first layer.

If you leave the width at 0.6 and change the bottom infill pattern to rectilinear it fills in more of it. It also doesn't seem to impact print time estimate at all.

I note there's a large gap between the perimeters of the band where it would sit in the head, is that intentional ? Turning on gap fill adds an extra perimeter in there but also add a few tiny printing areas and does impact the speed somewhat which is why I guess its turned off.

Anyway hope that helps.

RE: Strange toolpath render for edge

Save your project as .... that saves the .3mf file, zip it up and attach it to a post here. That the best way of debugging these sorts of issues. Without it help will be limited.

RE: Strange toolpath render for edge

Here is the project file. It includes two versions of the model - .stl and .obj files. I did this just to try out options and .stl came out much better, but very far from good.

Thank you for your time,

Edmunds

RE: Strange toolpath render for edge

Just in case - here is the .stl file in question.

Edmunds

RE: Strange toolpath render for edge

Also, I cannot get the bottom shell to close on the big curved section - I get two perimeter lines and thats it. Even with 100% infill ...

Edmunds

RE: Strange toolpath render for edge

@sprudzs-edmunds

Turn off detect thin walls. That is what is causing your issue with the edge of the shield. With your over wide extrusion widths of 0.8mm it cant print them as the edges are too thin but with detect thin walls on it tries to print that thin edge anyway. As its then gets processed different you get the separate printing action. When turned off it prints as you want.

Your extrusion widths combined with your infill pattern are also why you aren't filling in the bottom. Your first layer extrusion width of 0.6 is whats limiting the fill. If you drop it to 0.45 you will see that it tries to fill in more of the area. Unfortunately that effects the perimeters too as they are all first layer.

If you leave the width at 0.6 and change the bottom infill pattern to rectilinear it fills in more of it. It also doesn't seem to impact print time estimate at all.

I note there's a large gap between the perimeters of the band where it would sit in the head, is that intentional ? Turning on gap fill adds an extra perimeter in there but also add a few tiny printing areas and does impact the speed somewhat which is why I guess its turned off.

Anyway hope that helps.

RE: Strange toolpath render for edge

Also just noticed this other thing too, you have the default 0.2mm elephants foot correction turned on. That is shrinking all your first layers ALOT. If you reduce that to 0.1 you can fill in the perimeter gap without gap fill and the first layer looks massively better.

RE: Strange toolpath render for edge

@neophyl

Thanks so much, this got me out of chasing my own tail with this! I will try a test print now, but it looks so much better on screen already.

Edmunds

RE: Strange toolpath render for edge

Couldnt resist playing with this a bit more. But if I were printing this design I would use the settings and layout in the attached project.

3 masks in 3h30m

RE: Strange toolpath render for edge

@neophyl

Thank you! What were the most important alterations as to my settings, if you don't mind?

I got a version printed with corrected thin wall thing and elephant foot to 0.1, that is ok structure - not falling apart. The surface quality is so so. The most important problem is layer start blobs that are all over the place. I tried "back" and "align" seam align settings, but these came out even worse. I'm retracting heavily (6mm, bowden extruder) and retracting on layer change already. It seems I had less problem with this when slicing with Cura and also I could set X;Y for layer start, that moved the seam to a plase easy to remove. How do I best approach this in PrusaSlicer?

Thank you for your input,

Edmunds