Purge Extruder after large Ironing operation?

Hi new to the Prusa Slicer but fluent in S3D 4.01. I have a 2 fold issue with a particular model and not sure they are related but here goes.

This was with 2.3.0 Rc2, will retry with final release

The model is 197x147 and contains some single extrude circular walls that stand above the top surface. The top surface will have water on it so I wanted to give ironing a try. The results were fairly good for the most part considering I am using a .75mm Nozzle and .8 Extrusion width and purposefully on the edge of over extrusion to assure solid infill. I designed the mode to be printed with this nozzle so walls are .8mm thick.

The problem is the single extrude walls measure slightly thinner than the should be and was wonder if there is a way to cause a single extruder machine to purge the nozzle after an ironing operations that takes longer than a few minutes?

The other issue not related to ironing other than it may be magnified by lack of filament is that the slicer stops and starts the circular single walls in the middle of the wall leaving a hole due to retraction. Retraction is set the same as it was in the S3d and of course that slicer does not break the wall in the middle.

RE: Purge Extruder after large Ironing operation?

You could issue an M600 Filament Change command on the layer change to the single wall layer, this would require user intervention, but would purge the extruder by default!

Have you tuned linear advance?

you say that you have set up retractions the same as S3D... but don't say what values you have used... this might help.

In your other post you tried to add a .3mf file, but failed, possibly because you didn't zip the file...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Purge Extruder after large Ironing operation?

@joantabb

Retraction at 1mm on first print of the and second try dropped to .6mm at 40mm second. A this point I am fairly sure that purging the nozzle has nothing to do with the issue in the wall. It is the start and stop and restart of a single extrude wall. Luckily this does not render my part unusable and since this is ABS letting the extruder cook during the ironing is not really as big a problem as it would be with PLA.

I have not dabbled in manually editing the gcode to insert things but that shouldn't be difficult other than finding the proper location. I do like the ironing but it is also an interactive activity cleaning the nozzle with Tweezers and part with a spatula of the filament bit that are scraped off as it progresses..

RE: Purge Extruder after large Ironing operation?

@airscapes

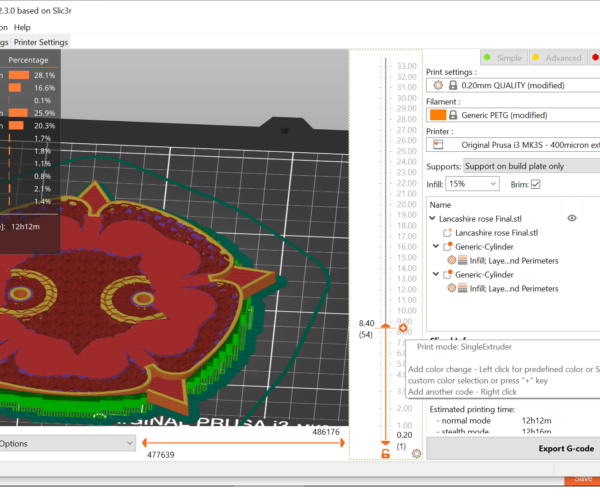

Hi, there is a facility to step through the layers on the sliced model, and automatically add the M600 at the level you want

in this instance I added a filament change at 8.4mm height as a demonstration by left clicking the + symbol on the scale in the vertical scroll bar

in the middle of the Prusa Slicer window...

this will cause the printer to stop at that level, and spit the filament out, you could change it, if you really wanted a colour change (or Material Change) or you can simply stuff the same filament back and purge the filament as desired...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Purge Extruder after large Ironing operation?

Is there a way to force the creation of a wipe / purge tower without doing a filament change (none MMU)?

I really like the ironing results and I use it a lot, but this problem (severe under extrusion after a large ironing job mid print) is the most common reason why I end up waist a few prints before I disable ironing.

My experience so far :

- Upping the ironing flow from 15% to 28% gives me good ironing results without running dry on larger area's, and does not create over extrusion. But it still gives under extrusion at next layer resulting in weak parts of even none attached parts on the next layer.

- Flow rate of 30% starts does attach small parts on the next layer, but under extrusion is still visible. But now I get over extrusion build-up on larger areas.

I decided my best bet is to just purge the nozzle after a large ironing job, but I can't do that by hand. So M600 (filament change) is not an option for me. I wanted to enable a wipe tower that is used for filament color changes, but it seems the slicer decides when it adds one and a user seems not able to over-rule this. Is there still a way to over-rule me wanting a wipe tower?

Creative Engineer and 3D printing @ AcEcraft.eu

RE: Purge Extruder after large Ironing operation?

Hi, have you solved this? I'm having the exact same issue.

RE: Purge Extruder after large Ironing operation?

Hi. I would also like to be able to do a quick filament purge after ironing. I think the filament is going so slow inside the nozzle that it is overcooking while ironing.

- As suggested above, increasing ironing flow rate may also reduce overcooking the filament since it pass less time inside the nozzle.

- Reducing nozzle temps at the minimum that your filament supports may also help in that mater.

- Ironing a little faster too.

An other reason why the next layer would have adherence problems would come from too much cooling. I have tried turning off cooling while ironing an intermediate surface. Had to edit g-code but it worked. I got better adherence for the next layer. Since ironing take time, cooling effect was too much. It can cool on its own.