Prusaslicer skipping 3 layers before starting supports

Hello all,

I am printing something that requires supports on both the inside and outside, the outside supports are printing ok but others just end up being a blob on the nozzle and heat block since it skips 3 layers before laying down the support material. Any thoughts on what I need to change?

Please save your project as a .3mf file

Files > Save Project as

Zip the .3mf and post it here. It will contain both your part and your settings for us to diagnose.

Cheerio,

RE:

Here is the file.

RE: Prusaslicer skipping 3 layers before starting supports

I attached the file, thanks.

Please save your project as a .3mf file

Files > Save Project as

Zip the .3mf and post it here. It will contain both your part and your settings for us to diagnose.

Cheerio,

RE:

I am printing something that requires supports on both the inside and outside, the outside supports are printing ok but others just end up being a blob on the nozzle and heat block since it skips 3 layers before laying down the support material. Any thoughts on what I need to change?

I don't know whether that is your problem, but before I got my MINI+ and used PrusaSlicer, I printed on Ender-5 printer of younger son with cura as slicer. When I loaded a part (STL) and did move it before slicing, sometimes I accidentally moved it down in Z direction. Everything that was below z=0 simply got truncated and did not appear in generated gcode.

So if you moved parts, check whether you did not accidentally move below z=0.

I used that feature to print only part of an STL I found on thingiverse. Turned it with cura and then moved that part I was not interested to z<0.

P.S:

I did that before 3Dprinting my own 10000lm led holders for capturing self 3Dprinted supersonic airgun pellets inflight with five 2µs duration flashes (pellets are not really sharp because they moved >7mm during 2µs of exposure):

https://forums.raspberrypi.com/viewtopic.php?t=319956&hilit=chronograph&start=25#p1956584

RE: Prusaslicer skipping 3 layers before starting supports

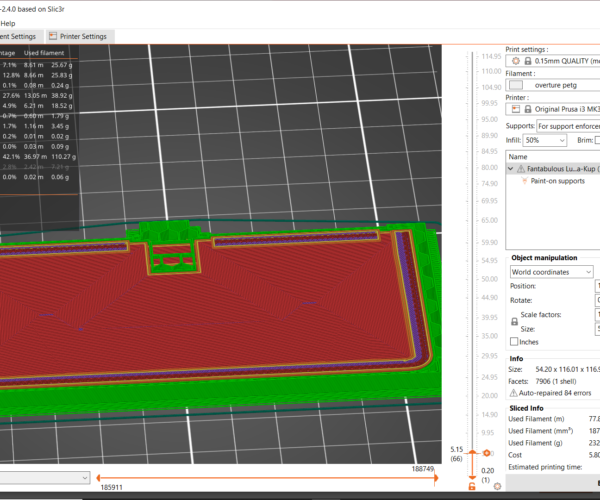

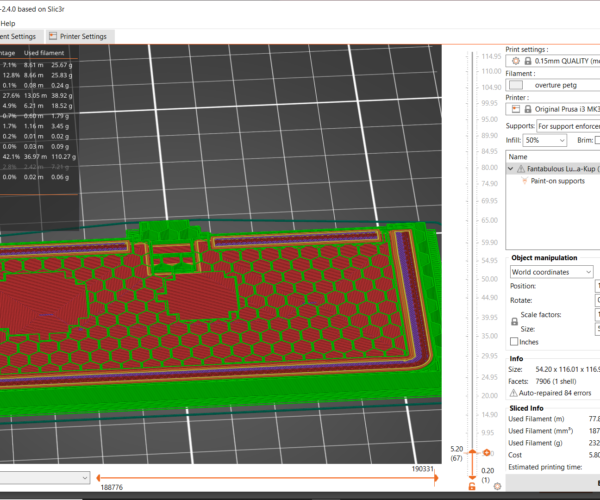

The project you attached does not match your pictures at all. The part is different and your support settings are completely different too. Your support is pictured using honeycomb but the project is showing as the default rectilinear pattern

How are we supposed to diagnose a different project ?

RE: Prusaslicer skipping 3 layers before starting supports

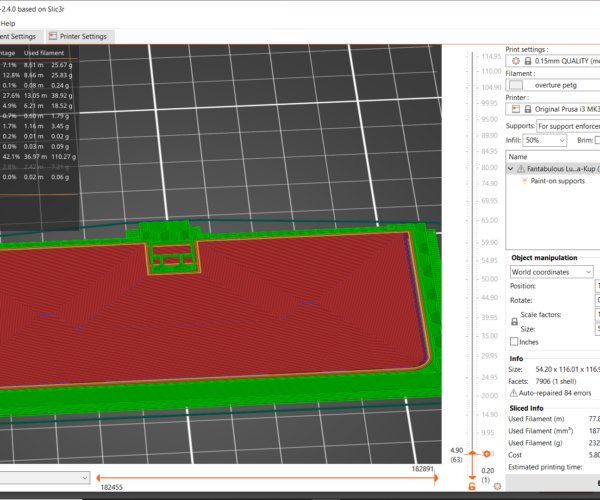

It is the same part just flipped, it does this on all its faces. It also does it on all pattern types as well, the rectangular grid being what I like to use. Here it is as in the photo, but set to the rectangular grid pattern box-flipped (2)

The project you attached does not match your pictures at all. The part is different and your support settings are completely different too. Your support is pictured using honeycomb but the project is showing as the default rectilinear pattern

How are we supposed to diagnose a different project ?

RE: Prusaslicer skipping 3 layers before starting supports

@3dprinteverything: post the .3mf that resulted in the behavior you describe or it didn't happen.

Mk3S+,SL1S

RE: Prusaslicer skipping 3 layers before starting supports

The thing is that the initial project you posted has the optimal orientation for that part. Anything else just generates too much unneeded support. The problem is that you are using grid. Snug support works much better and when sliced the support looks ok. If I had to print this then I would do the support as in the attached project.

Of course if I were printing it then I would change a bunch of other settings too. The top/bottom infill to something other than concentric, its the worst pattern there is as it leaves gaps. I would also up the perimeters to 3 as I don't print with less 🙂 and it makes it print faster and it will be stronger too. The infill is also less than optimal. Cubic with a lower % would be better. Basically I've included a second project in the zip with how Id really print it as far as print settings. Things like changing the layer height to 0.2 but using variable set to a min of 0.1 on the curves etc. All speed things up. Changing the angle of the support will make it easier to get into it to remove it. Stuff like that. Lots of small things.

I do have some questions about your original settings though. The filament profile is showing as a modified Prusament PLA profile when loaded. But you have modified the type to be PET, not pla. So which filament are you using ? As that will determine what the cooling should be. Those settings could be at the root of your problems, rather than the print settings. As the print temps are more like for PET but the cooling is more like for pla. Its a bit of a strange hybrid.

If you are having to heat the bed to 85 degrees for pla to get it to stick then I would start to question if your first layer is adjusted correctly or if the bed is clean. Then again that depends on the bed type, smooth/textured/satin.

Where did you get the file? It looks like a part intended for injection moulding, it's always going to be a difficult print ...

do you have access to the original design?

And your settings are decidedly odd, what filament are you printing? This configuration seems to be a hybrid of two different types. What are the manufacturer's recommended settings?

It would be easier to start from a tested preset or to use a filament for which a preset already exists.

Cheerio,

RE: Prusaslicer skipping 3 layers before starting supports

The Settings are from the original version of Prusa slicer, back in those days prusa didn't have prusament petg or pet to model it from thus I went with changing the temperatures which oddly enugh worked well until now. I print with overture petg and have been for years, I did go back and change the filament settings to match prusament petg settings minus the temp settings as they are a little on the high side for my particular petg. I added your suggestions as well. Perhaps I should tweak these settings some more.

With a bit of messing around, I did manage to figure out what setting I need to mess with. I messed with the z contact distance and this made it printable. Part of the problem being I probably should be using water-soluble supports but I'm lazy and just sand them off if need be. in this case, ill be gluing some other parts on so either way id be sanding and painting anyhow.

The thing is that the initial project you posted has the optimal orientation for that part. Anything else just generates too much unneeded support. The problem is that you are using grid. Snug support works much better and when sliced the support looks ok. If I had to print this then I would do the support as in the attached project.

Of course if I were printing it then I would change a bunch of other settings too. The top/bottom infill to something other than concentric, its the worst pattern there is as it leaves gaps. I would also up the perimeters to 3 as I don't print with less 🙂 and it makes it print faster and it will be stronger too. The infill is also less than optimal. Cubic with a lower % would be better. Basically I've included a second project in the zip with how Id really print it as far as print settings. Things like changing the layer height to 0.2 but using variable set to a min of 0.1 on the curves etc. All speed things up. Changing the angle of the support will make it easier to get into it to remove it. Stuff like that. Lots of small things.

I do have some questions about your original settings though. The filament profile is showing as a modified Prusament PLA profile when loaded. But you have modified the type to be PET, not pla. So which filament are you using ? As that will determine what the cooling should be. Those settings could be at the root of your problems, rather than the print settings. As the print temps are more like for PET but the cooling is more like for pla. Its a bit of a strange hybrid.

If you are having to heat the bed to 85 degrees for pla to get it to stick then I would start to question if your first layer is adjusted correctly or if the bed is clean. Then again that depends on the bed type, smooth/textured/satin.

RE: Prusaslicer skipping 3 layers before starting supports

Yes, for whatever reason my settings changed name, but you are correct that other than the temp settings I needed to tweak the retraction and whatnot for petg. Oddly enough they worked well minus a little stringing, certainly not the most amount of stringing ive seen.

For filiment i use overture petg

230-250 235 for first layer and 230 for the rest seems to be the strongest.

The heat bed I set to 80 which also seems to stick great too. Unless its a thin object like a lithophane but that's a given, you'd need a footprint for that kind of work anyhow otherwise it might tip over.

As for the part in question, I modeled that for a senior design project. I thought of making it 2 pieces but wanted to try supports since I don't use them much. It seems however I need to use soluble supports so i can lower the z contact distance as this was what was causing the problem so it seems.

Where did you get the file? It looks like a part intended for injection moulding, it's always going to be a difficult print ...

do you have access to the original design?

And your settings are decidedly odd, what filament are you printing? This configuration seems to be a hybrid of two different types. What are the manufacturer's recommended settings?

It would be easier to start from a tested preset or to use a filament for which a preset already exists.

Cheerio,

Soluble supports will help. Try replacing all the rounded corners with 45 degree chamfers to reduce the post processing.

The attachment lug on the bottom (as oriented in your file) is obliging the slicer to create a lot of support and a large area where the surface will suffer, if you can make the lug flush it will also simplify matters.

Cheerio,