PrusaSlicer produces gaps and a bad print, many retractions produce an uneven surface.

Here is the ProjectFile.3mf

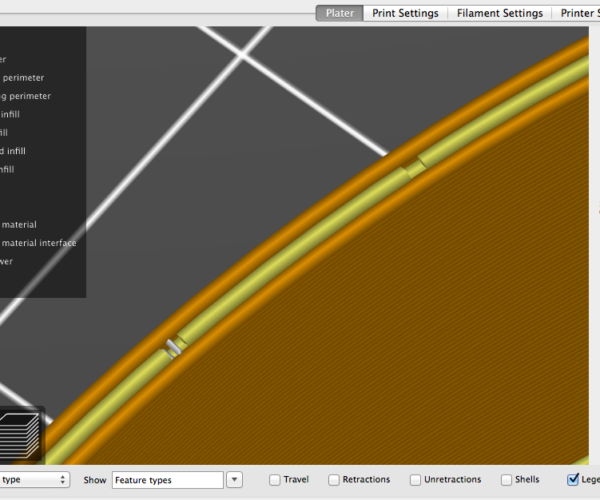

The outer perimeters are OK, my model is watertight and has a volume.The inner parameters are broken into pieces and filled with "GapFill" (gray)

Why?

I printed the model with transparent PET. It looks not fine.

What can I change ? Carsten

RE: PrusaSlicer produces gaps and a bad print, many retractions produce an uneven surface.

this are the pictures off all 4 sides.

2 sides are good (as in the PrusaSlicer) 2 sides are not so pretty.

RE: PrusaSlicer produces gaps and a bad print, many retractions produce an uneven surface.

As a work-around until this matter is successfully addressed by the slicer, there is a software module in later Marlin Arduino code that attempts to deal with the problems associated with stops, starts, and sharp corners. "Linear advance" in Marlin applies a spring constant, based on the elasticity of the Bowden tube extruder system, to calculations which contribute to commands to the extruder. It tries to move the filament (in either direction) so as to maintain a pressure at the nozzle that is appropriate to its velocity, in order to deliver the correct amount of material continually. The situation is especially critical at stops, starts and sharp corners. Linear advance calculates the extruder motion in able to accomplish what it needs to do with regard to what the x and y are doing. Additionally, if the extruder speed is too limited to keep up with what the calculation calls for, then the x and y speeds are are reduced. The "K factor" is the adjustable element of the linear advance module. Currently I use a K of about 1.25 for PLA, and about 4 or 5 for TPU.

http://marlinfw.org/docs/features/lin_advance.html

RE: PrusaSlicer produces gaps and a bad print, many retractions produce an uneven surface.

Linear advance is already used in Prusa Slicer Profiles...

here is a clip from a recent print...

-------------------------

G21 ; set units to millimeters

G90 ; use absolute coordinates

M83 ; use relative distances for extrusion

M900 K30 ; Filament gcode

;BEFORE_LAYER_CHANGE

G92 E0.0

;0.2

------------------------------------------------

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK