prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

Hi all, trying to move from cura to prusaslicer, i have a delta printer with Y bowden tube to print 2 color. I made some test and it work but some parameter and behavior i do not understand (note i'm note english) so looking for help for tuning change material process.

Explain:

during print, when one color (we say color#1) end the layer and need to change, printer made this movement:

a) go to prime tower (ok)

b) prime some material still #1 (what is this time/mm? need to reduce)

c) retract material #1 some mm (i think about 10)

d) move empty nozzle on prime tower (why? need to reduce to 0 this time)

e) retract material to park position (ok)

f) move slowly material #2 a bit, i think 20mm (what is this time ? i need to change)

g) move with more speed #2 (what is this time ? i need to change)

h) prime material #2 on prime tower (ok)

Can some one tell e about above movement which parameter are involved ?

Also, what is in "purging volume" the "volume unload" parameter ? changed from 70 t0 10 but i do not see change in print...

I see also a problem on layer 1, when color#1 is finish printer change color and print material#2 but di not elevate nozzle so nozzle bump on already printed part with color#1; this appear only for layer1 (it si normal? i tried "avoid crossing perimeter but no result).

Thanks to all, i hope to not be excessive

Marco

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

no one can help me ? also partial answers maybe useful.

thanks

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

have problems printing 2 colors

my G code works in Simplify3D, and in PrusaSlicer

completely refuse. what am I doing wrong in a tool change script ????

I use a Y tube and 2 stepper motors.

I like your product and your printers, but unfortunately I live poorly and cannot afford to buy your printer for it as well, MUU2.

G90

G1 X ...xlocation Y ...ylocation F4800; Move X Y for tool change

T[old_tool]; Select Old Tool

G92 E0; Zero Extruder

G91; Relative Coordinates

G1 E-15 F3600; Fast Retract 15mm

G4 P600

G1 E13 F3600; Fast Reinsert 13mm

G4 P1000; Pause 1secs

G1 E-13 F3600; Fast Reinsert 13mm

G4 P1000; Pause 1secs

G1 E-548 F3600; Fast long retract 548+2mm

G90; Absolute Coordinates

G92 E0; Zero Extruder

T[new_tool]; Select New tool

G92 E0; Zero Extruder

G91; Relative Coordinates

G1 E548 F3600; Fast insert 548mm

G4 P1000; Pause 1secs

G1 E10 F300; 5mm/s Feed 10

G4 P1000; Pause 1secs

G1 E3 F150; Feed 3mm

G4 P1000; Pause 1secs

G1 E4 F75; Feed 4mm

G4 P1000; Pause 1secs

G92 E0; Zero Extruder

G90; Absolute Coordinat

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

I believe Prusa Slicer uses T0, T1, T2, T3, T4 for the five extruders...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

Later I'll check my change tool scripts

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

https://1drv.ms/u/s!Ar8zmT5x2zsGhIcdYhmImLBNdpLjXQ

https://1drv.ms/u/s!Ar8zmT5x2zsGhIceeZ3ijqRQm5hnIA

have problems printing 2 colors

my G code works in Simplify3D, and in PrusaSlicer

completely refuse. what am I doing wrong in a tool change script ????

I use a Y tube and 2 stepper motors.

I like your product and your printers, but unfortunately I live poorly and cannot afford to buy your printer for it as well, MUU2.G90

G1 X ...xlocation Y ...ylocation F4800; Move X Y for tool change

T[old_tool]; Select Old Tool

G92 E0; Zero Extruder

G91; Relative Coordinates

G1 E-15 F3600; Fast Retract 15mm

G4 P600

G1 E13 F3600; Fast Reinsert 13mm

G4 P1000; Pause 1secs

G1 E-13 F3600; Fast Reinsert 13mm

G4 P1000; Pause 1secs

G1 E-548 F3600; Fast long retract 548+2mm

G90; Absolute Coordinates

G92 E0; Zero Extruder

T[new_tool]; Select New tool

G92 E0; Zero Extruder

G91; Relative Coordinates

G1 E548 F3600; Fast insert 548mm

G4 P1000; Pause 1secs

G1 E10 F300; 5mm/s Feed 10

G4 P1000; Pause 1secs

G1 E3 F150; Feed 3mm

G4 P1000; Pause 1secs

G1 E4 F75; Feed 4mm

G4 P1000; Pause 1secs

G92 E0; Zero Extruder

G90; Absolute Coordinat

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

How to write scripts for your slicer? so that he is correct and works for May Marlin.

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

@joantabb

my dear interlocutor, give an example of the G-code. it will work without any effort.

For Y pipes through a bolden with two motors and one E3DV6.

If I use Google translator, they may not be accurate in words.

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

How to write scripts for your slicer? so that he is correct and works for Marlin.

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

Goog afternoon Rtyuuu,

please find attached a zip fie

this file includes :-

the original 3D model file from autodesk 123D Design,

plus the two STL's - words and background

plus the Prusa Slicer3mf file which holds all of the slicer configuration,

plus the Gcode

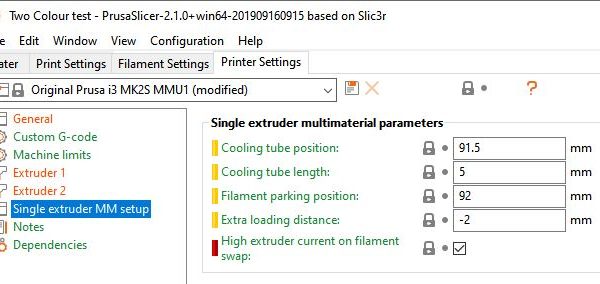

this is set up to run on a mk2 printer with MMU1 (bowden feed single E3Dv6 extruder setup)

the mmu1 bowden single E3dv6 configuration is as follows

this means that the two bowden pipes join at the multiplexor closer than 91.5 mm above the nozzle

if your setup is different you will have to reconfigure the prusa slicer software and re slice the model.

this link may help... https://www.sublimelayers.com/2017/06/first-week-with-prusa-mm-quad-extrusion.html

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

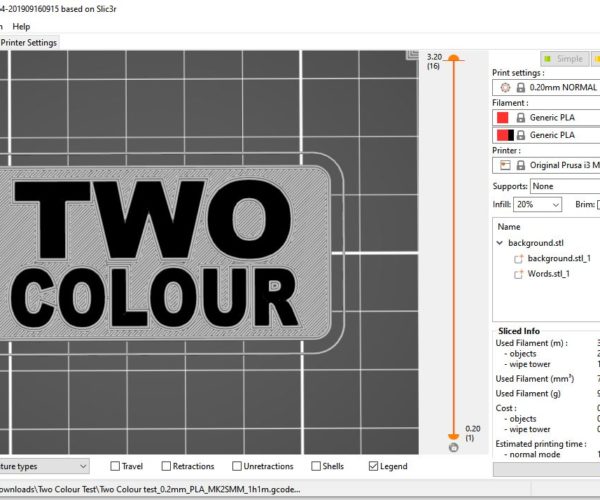

this picture gives you an idea of the prusa multi material setup

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

@joantabb

dear thanks I will try how my homemade printer stops printing. And you’ll be sure to turn it off or not. Thanks again. It turns out that you don’t need to write a script, did I understand you correctly?

😉

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

Prusa Slicer has a profile for mk2 printer with multi material unit 1, that is a bowden printer

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

Hi @rtyuuu1983 , sorry for delay.

yes as Joantabb say with prusaslicer 2 there is not a "change tool script" to use... everything is configured from standard gui

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

@joantabb

In general, I set my values and the extruder did not pull out 550 mm of plastic. I don’t understand why such a simple setup does not work?

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

@marco-tonoli

what am I doing wrong???

I need to stretch 550 mm (e1) threads and stick in 550 mm (e2)

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

People who taste how to solve a problem,

two-color printing in the settings. The problem is that I have a bolden of 550 mm from the multiplexer. And the slicer cuts so that it does not extend this length, but switches immediately from the first to the second stepper motor

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

i'm not sure to understand your situation.

I have a delta printer, with 1 nozzle and a Y splitter and 2 motor, so i have from nozzle to motors:

a) nozzle

b) extruder

c) a short tube to Y (more or less 30mm)

d) y splitter

e) more or less 2 tube about 550mm from splitter to motor extruder.

In this configuration, i put material #2 a 150mm from nozzle, material #1 to nozzle ready for print and launch print.

i have this config:

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

and this (only 1 file i can insert ?)

RE: prusaslicer 2.1, dual material. Can someone explain some of this parameters ?

@marco-tonoli

thanks for the config, I'll try unsubscribe