Prusa Slicer possibly overextruding with 0.3mm nozzle

So I had an issue with bad overhangs and I am pretty sure now that it is due to overextruding even though I am confident the settings in the Prusa Slicer (2.4.1) are okay.

1) the problem only appears on the 0.3mm printer and

2) can be worked around if I reduce the flow by about 15% (!) on the printer (Marlin 1.9something)

3) using slic3r with virtually the same settings produce a very good print with 100% flow rate

4) Prusa Slicer produces also perfect prints on my other printer (also Marlin 1.9something) with an 0.4mm nozzle - same filament etc.etc.

Anyone having the same experience - or suggestions what else could be the cause?

Best Answer by Neophyl:

Considering you say the settings are near the 'same' there are quite a few differences in the 2 output gcode files you included in the zip file. And the settings stored at the ends.

For a start the Slic3r version is NOT sending the machine limits out to your printer. You have PS configured to include them into the gcode so they are over riding whatever is in the printer. Now on its own this may not be a problem, if the limits in your printer firmware are similar to those being sent then it wont cause any problems. If they are different though...... I leave that one up to you to decide.

The PS gcode has over 3000 more lines so there other fundamental differences too, although I'm not sure why there's such a big difference.

The Slic3r settings (stored at the end of the gcode) say that the firmware flavour is set to Reprap. Your PS project has Marlin(Legacy) selected. That's going to cause differences I would think. At least set it like for like on a comparison test.

The slowdown if layer time is below values for Slic3r and PS are very different. PS=20 seconds and Slic3r=5 seconds. For a part this small the layer time slowdown is almost certainly applicable and I can see a difference on infill speeds when the value in PS is set to the same as Slic3r.

So PS is slowing down and I'd guess slic3r is not. That will cause a big difference in print speeds on something this cross section. That all plays into part cooling etc when this happens. Something else to compare. Also in the same area the slic3r has a min print speed set of 10 while PS has 15. So your earlier statement that the speeds are identical is only partially true. The filament settings can over ride those and have caused confusion to others in the past.

Your retraction speeds are also different. I've found that can make a difference to print quality on seams. As your pics would seem to show lots of difference on the seams area that value should also be set to the same for future tests.

Those are just the obvious ones that jumped out to me. Bound to be other more subtle ones as the software has diverged quite a bit.

Just because a setting works fine in one slicer does not mean it will in another. Even if they share a common ancestry.

I point this out on the Super Slicer github too and SuSi and PS are far more closely related but the results of the same settings can be radically different. They are not interchangeable in many instances.

So I wouldn't expect that PS and Slic3r work the same any more either.

Following are just some mental musings on your PS settings.

100% cooling on petg ? unusual

Solid infill on the entire height from your solid infill threshold value. Wouldn't personally print like that as its just asking for heat related build up. Maybe that's why the fan is at 100% ? With petg then lots of contraction and probably weaker inter layer adhesion.

Thanks for providing a fun distraction to other things 🙂

Pictures?

Cheerio,

RE: Prusa Slicer possibly overextruding with 0.3mm nozzle

Yeah, I would like to see images before commenting also.

Regards

Swiss_Cheese

The Filament Whisperer

RE: Prusa Slicer possibly overextruding with 0.3mm nozzle

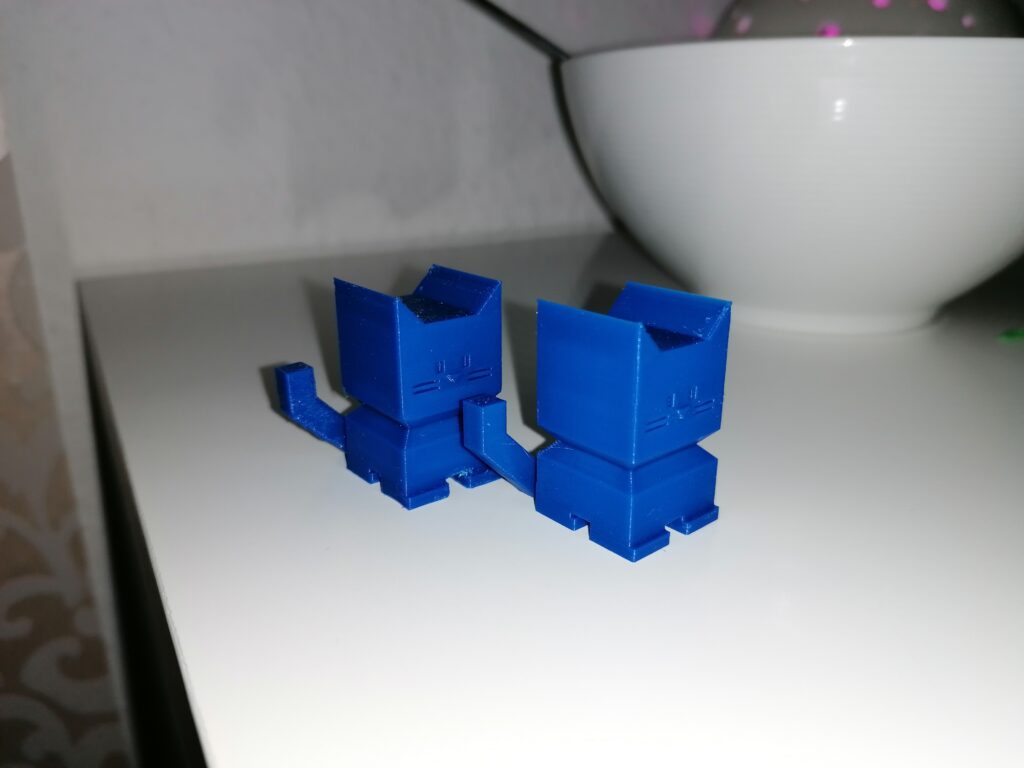

so this 7x7mm 45° tower was printed with a 0.3mm E3D NozzleX at 0.2mm layer height, PETG 245°C, cooling at 100% starting at 3rd layer - perimeter speed 50 and 60mm/s (no difference). Also it prints flawlessly with the same settings when sliced with slic3r.

0.2mm layers with a 0.3mm nozzle is never going to give much better than draft quality. Try with 0.15mm layers.

Cheerio,

RE:

Correction: I was printing 0.15mm layer height - but - layer height has really nothing to do with the issue of a bulging overhang for once - also I get a perfect print of the same part with the same 0.15mm layer height sliced with slic3r - so "never" is sort of a strong word 😉

Back to the topic: Any ideas why the Prusa Slicer overextrudes with a 0.3mm nozzle but not with an 0.4mm nozzle?

RE: Prusa Slicer possibly overextruding with 0.3mm nozzle

@md-fo

To much heat, printing to fast in a small area, reduce the filament temp (as much as you can), reduce the bed temp(as much as you can), add a small brim to help with adhesion, and slow the print speed waaaaaay down. you mentioned your perimeter speed 50 and 60mm/s (no difference), this is most likely because your part is so small it governed by the "Small perimeters:" which by default is 25mm/s try changing it to 5 or 6mm/s. I don't know the size of the part but based on your images this seems likely to be the case.

Good Luck

Swiss_Cheese

The Filament Whisperer

What else are you not telling us? Please save your project as a .3mf file

Files > Save Project as

Zip the .3mf and post it here. It will contain both your part and your settings for us to diagnose.

RE: Prusa Slicer possibly overextruding with 0.3mm nozzle

Hey guys!

I included the 3mf file along with the output from PrusaSlicer (redundand I guess, but to be sure) and Slic3r as well.

I also noticed that Slic3r tends to use a bigger extrusion width on AUTO setting so I also tried to set them manually in PrusaSlicer - still I get this bulgy surface of the Overhang.

Thanks a lot for your effort so far!

Cheers,

Md Fo

RE: Prusa Slicer possibly overextruding with 0.3mm nozzle

@Swiss_Cheese

This 7x7mm tower is just for quick tests - I get the bad overhangs on all parts - eg. the neck of the original size Calicat and thats 20x20mm - far off the heatbed. Also I have the exact same speed settings on Slic3r with no problems there.

I'll try your suggestion for 5mm/s on small serimeters right away just to be sure.

Thanks for your help!

RE: Prusa Slicer possibly overextruding with 0.3mm nozzle

I reduced the small perimeter speed from 15mm/s to 5mm/s as @Swiss_Cheese suggested and that resulted in a big improvement. The bulging is not gone but now it went down to 0.2mm at the worst spot in the overhang - still a bigger than in the slic3r prints but acceptable.

Still the question remains why slic3r can print this part a lot faster with better results.

An odd .3mf, what printer is this?

The fill settings are odd - but the part slices and prints OK with i3 0.4mm nozzle 0.2mm layer settings.

Cheerio,

RE: Prusa Slicer possibly overextruding with 0.3mm nozzle

Thanks! I printed the part on my other printer with the same settings as you (0.4mm Nozzle, 0.2mm layers) - and it just prints perfectly - that's exactly what's puzzling me.

RE: Prusa Slicer possibly overextruding with 0.3mm nozzle

The printer was an Ender2 but I switched the hotend to an original E3DV6 with a 0.3 hardened nozzle, geared metal extruder, new sorftware, diods for decoupling the steppers, added a radial cooler etc. etc. It has been a fun journey. 😉

RE:

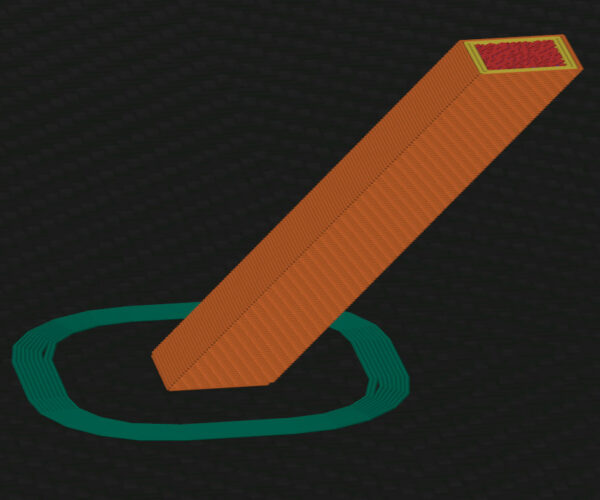

This is Prusa Slicer (left - 2:28h print time) vs Slic3r (right 1:56h).

Your first layer is a little thick for a 0.3mm nozzle - 0.15mm would be my first setting.

You might experiment with thick bridges and the bridging angle.

Cheerio,

RE: Prusa Slicer possibly overextruding with 0.3mm nozzle

While I really appreciate all of your hints my main issue still is:

Why is the Prusa Slicer printing slower and in a significantly worse quality that the Slic3r with practically the same settings?

I'll contact Prusa and see if they are interested

I suspect it is related to the strange way your fill is behaving. I don't have a 0.3 nozzle to try it with.

Cheerio,

RE: Prusa Slicer possibly overextruding with 0.3mm nozzle

Considering you say the settings are near the 'same' there are quite a few differences in the 2 output gcode files you included in the zip file. And the settings stored at the ends.

For a start the Slic3r version is NOT sending the machine limits out to your printer. You have PS configured to include them into the gcode so they are over riding whatever is in the printer. Now on its own this may not be a problem, if the limits in your printer firmware are similar to those being sent then it wont cause any problems. If they are different though...... I leave that one up to you to decide.

The PS gcode has over 3000 more lines so there other fundamental differences too, although I'm not sure why there's such a big difference.

The Slic3r settings (stored at the end of the gcode) say that the firmware flavour is set to Reprap. Your PS project has Marlin(Legacy) selected. That's going to cause differences I would think. At least set it like for like on a comparison test.

The slowdown if layer time is below values for Slic3r and PS are very different. PS=20 seconds and Slic3r=5 seconds. For a part this small the layer time slowdown is almost certainly applicable and I can see a difference on infill speeds when the value in PS is set to the same as Slic3r.

So PS is slowing down and I'd guess slic3r is not. That will cause a big difference in print speeds on something this cross section. That all plays into part cooling etc when this happens. Something else to compare. Also in the same area the slic3r has a min print speed set of 10 while PS has 15. So your earlier statement that the speeds are identical is only partially true. The filament settings can over ride those and have caused confusion to others in the past.

Your retraction speeds are also different. I've found that can make a difference to print quality on seams. As your pics would seem to show lots of difference on the seams area that value should also be set to the same for future tests.

Those are just the obvious ones that jumped out to me. Bound to be other more subtle ones as the software has diverged quite a bit.

Just because a setting works fine in one slicer does not mean it will in another. Even if they share a common ancestry.

I point this out on the Super Slicer github too and SuSi and PS are far more closely related but the results of the same settings can be radically different. They are not interchangeable in many instances.

So I wouldn't expect that PS and Slic3r work the same any more either.

Following are just some mental musings on your PS settings.

100% cooling on petg ? unusual

Solid infill on the entire height from your solid infill threshold value. Wouldn't personally print like that as its just asking for heat related build up. Maybe that's why the fan is at 100% ? With petg then lots of contraction and probably weaker inter layer adhesion.

Thanks for providing a fun distraction to other things 🙂