Prusa 2.6.0-alpha4 Cut Tool

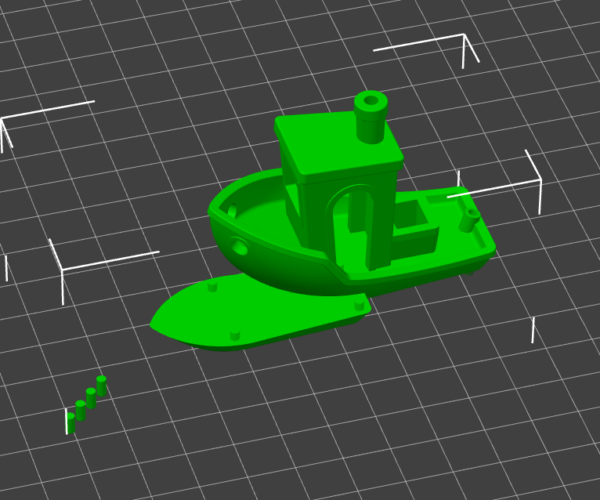

Any idea what I'm doing wrong with cut tool? I select object, select cut tool, drag cut plan to where I want to make cut, edit connectors, select dowel (which I thought should make dowel holes in each new part and also create dowel pins), confirm connectors, both objects are selected with "keep orientation", Cut to: Objects is selected and once I select peform cut, it makes the cut but overlaps the two parts, creates dowel pins but also has dowel pins inserted in each part. See screen shot.

RE:

@3ddavidson

I'm guessing you are very new to prusaslicer. For starters you did the procedure correctly, you may have only forgotten to do one thing, and that's size your dowels for tolerance, this is not done automatically because different materials will have diffident needs. It's normal for Slicer to place the parts on top of each other like that after cutting, you just have to select them if they are overlapping and move them so that they aren't.

The pins that your seeing in/on the model are not dowels, they are Negative Volumes marking the whole positions, and at the time of rendering will create the wholes for the dowels, you would have seen this if you had pressed the Slice now button.

Anyway I hope that's got you sorted, have fun with it and play lots.

RE: Prusa 2.6.0-alpha4 Cut Tool

No, I'm not new to Prusa, I've been using it a long time. I am new to 2.6.0 alpha4. When I "perform cut", prusa groups the bottom part, the upper part and the dowels all as one object. But I did find that you can ungroup them by selecting the "arrange" tool.

RE: Prusa 2.6.0-alpha4 Cut Tool

@3ddavidson

When you "perform cut" with the settings you used, slicer is actually breaking your single "Object" into multiple "Objects", Not Grouping them together. After it splits them to "Objects" if you have selected dowels, the "Dowels" are split to separate "Objects" and printed as such, If you have 4 dowels you will see 4 new objects created in the "Object menu" named Dowel-Connector 1-4 by default. If you cut your original "Object" in two then slicer will also turn each of those half's into individual "Objects". Again If "Dowel" was selected, Slicer will add a Negative volume in the appropriate areas based on your selections before you "perform cut" at the time of render those Negative Volumes will become the aligned Holes for the dowels, as I mentioned to you in the previous post, you might want to consider adjusting the tolerances of the dowels.

After you "perform cut" all the New "Objects" in the "Object menu" are selected (Highlighted Green) by default, Not Grouped, you can simply left click anywhere on an empty area of the Platter, away from the selected "Objects" they will be deselected, and you can then simply left click on any of the new "Objects" created by the cut process and move it around on the platter.

Your image shows that you had Cut to: Objects selected, you had "Object A" (That's the top of the cut) Set to "Place on cut", and "Object B" set to "Keep orientation". You chose to use 4 Dowels so four dowels where created, they each of the dowels became a separate object, the dowels are the only new thing going on here, in previous versions of slicer (this is why I guessed you were new to slicer) it has always preformed the cut the same way, turning one object into 2 objects and dropping the new object to the bed overlapping a portion of the other, offset by 45°.

My assessment was not designed to embarrass you, but rather to offer an assessment of where I perceived your knowledge level of slicer based on the question you asked, it effects the answer.

Apologies if it had that effect, I'm a very blunt person. I find we waste less time that way.

RE: Prusa 2.6.0-alpha4 Cut Tool

@rd

Thanks so much! While I'm not new to Prusa Slicer, I know that I don't know everything there is to know about it. I typically don't learn features until I need them. I've used the cut feature before but never this way. Thanks for your help, much appreciated!!!

RE: Prusa 2.6.0-alpha4 Cut Tool

Why is there such a thing as tolerance? Wouldn't you want a close tolerance?

How does PrusaSlicer decide where the 'sloppiness' is applied? (randomly, average...?)

Thanks

@3ddavidson

I'm guessing you are very new to prusaslicer. For starters you did the procedure correctly, you may have only forgotten to do one thing, and that's size your dowels for tolerance, this is not done automatically because different materials will have diffident needs. It's normal for Slicer to place the parts on top of each other like that after cutting, you just have to select them if they are overlapping and move them so that they aren't.

The pins that your seeing in/on the model are not dowels, they are Negative Volumes marking the whole positions, and at the time of rendering will create the wholes for the dowels, you would have seen this if you had pressed the Slice now button.

Anyway I hope that's got you sorted, have fun with it and play lots.