Problem with slicing complex vase mode models

I make very complicated "vase mode" models. I was surprised prusa slicer does a decent job slicing them (you should see how nicely cura butchers them 🙂

I normally use simplify3d for these which slices them correctly. but when I share these files others are unlikely to have S3D so I check the files in prusa slicer.

sometimes it butchers the files and I have to tweak them till they work. sometimes I can't make them work.

This is one of those cases. I can't figure out what prusa slicer is choking on in the file. the segment its having an issue with slices fine when its by itself but with the additions it does not fail at the additions but in the segment that otherwise slices fine... strange.

Picture attached. it won't let me attach the STL but you can grab this file

https://drive.google.com/file/d/1XRu1R548YJzH0Qet_VDNunRBHcHXJeLn/view?usp=sharing

That is the STL file. now prusa can't slice it stock there is am important setting you must alter. Minimum Gap has to be set to 0 this is because there are 0.01mm "slivers" in the model that makes the complex vase mode printing possible.

0.4mm 0.2mm min and max set to 0.2mm no top layers no bottom layers single wall spiralize vase mode.

there should be no retractions or travel movements except at the very start and the very end. its one continuous extrusion from start to finish. (trust me it works)

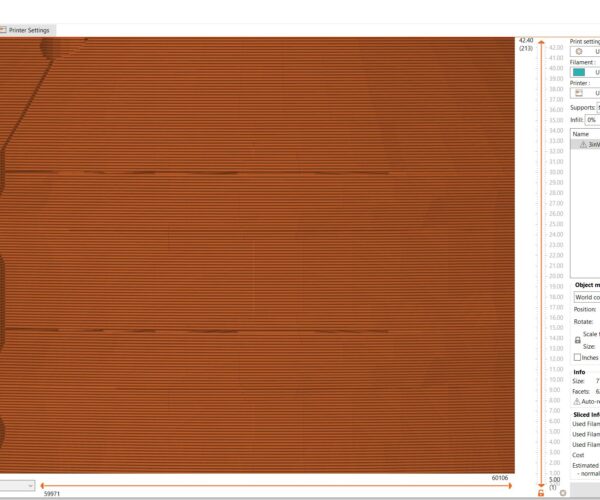

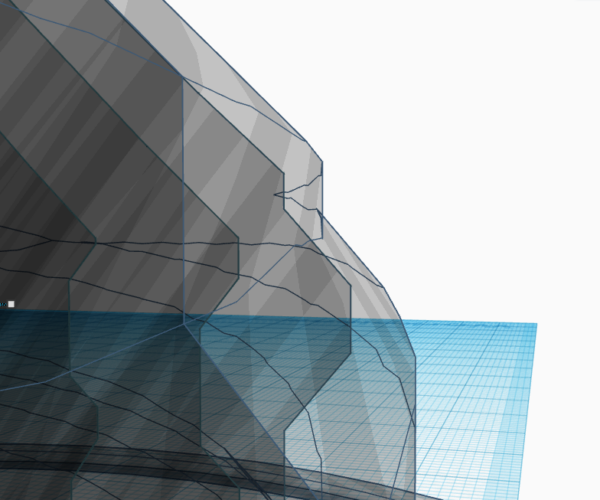

look at the "slice" that goes all the way to the outside. notice the two segments that are missing (and the missing bit is more extensive inside) this is one of the more minor cases of it whacking my files

any suggestions on how I can make it slice it correctly? My suspicion is its finding errors in the model (common from tinkercad but rarely fatal) and one of the "corrections" it makes "deletes" a portion of the model.

Best Answer by Neophyl:

I don't normally download models not zipped up and saved here but I did this one as the problem is interesting. However when I sliced your model (even with the PS reported errors) I am not getting the pictured gaps. I am using PS2.6a4.

So what version are you using ? Also this absolutely the reason we ask for a zipped up project file (3mf) saved from Prusa Slicer as that way we get a copy of all the settings you are using.

I did take the stl in to blender and removed the (very minor errors) that were in it and so I have a version that PS doesn't indicate any problems with. The only 'problem' is that the both look to slice the same. The following is your original model sliced in 2.6 and with a normal profile set to vase and 0.4 external perimeter with closing radius of 0 as you describe. It looks normal.

Those discontinuities mentioned though will cause gaps in the surface as the filament goes from point a to be and 'cuts the corner'. Better to bring the verts into alignment to make the print stronger.

RE: Problem with slicing complex vase mode models

Good afternoon,

to my understanding, this model cannot be printed in true vase mode because it has a number of holes in the middle

It must, by default stop and start to create the different sets of outer perimeters, Additionally, as you suspect there are errors in the STL

you could try right clicking on the model and choosing 'Fix through the Netfabb' This may find more errors to fix.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Problem with slicing complex vase mode models

Your understanding is incorrect but it's also understandable this is a complex vase mode model if you don't know what you're looking at you might think it's not compatible

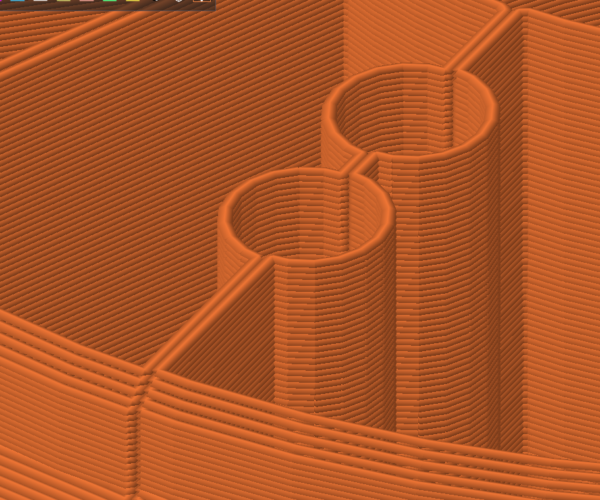

If you look on the side of the model you'll see there is a slice going all the way through the model from the inside to the outside this connects the insight surface to the outside surface so that there is no inside surface there is now only one outside surface

All of the other slices you see do not fully penetrate the model they moved within 0.8 mm of the outer surface of the model these are ribs they move close enough to fuse with the outer surface but not close enough to break the outer surface thereby not violating vase mode constraints

The model is fully vase mode compatible and slices perfectly fine in simplify 3D

How do I turn off the error correction in prusa slicer? Maybe that's the problem it's correcting something that does not need to be corrected

If you are still confused about how vase mode works that's understandable I have a video on that if you go to todays3Dprint.com and look at the second to last video that I posted last week it's about an hour long it explains how complex vase mode works and how to do it

RE: Problem with slicing complex vase mode models

I guess Joan knows what Vase mode is for sure ... 😀

It takes some time to understand how this is modeled, but i got it ... I admit, the modeling is really somewhat "artistic" 😀

But i ask myself why you want to print this in vase mode. As it sems to be a mechanical part, i can hardly imagine it comes out sturdy enough.

The area where the ribs hopefully fuse with the outer surface is quite small.

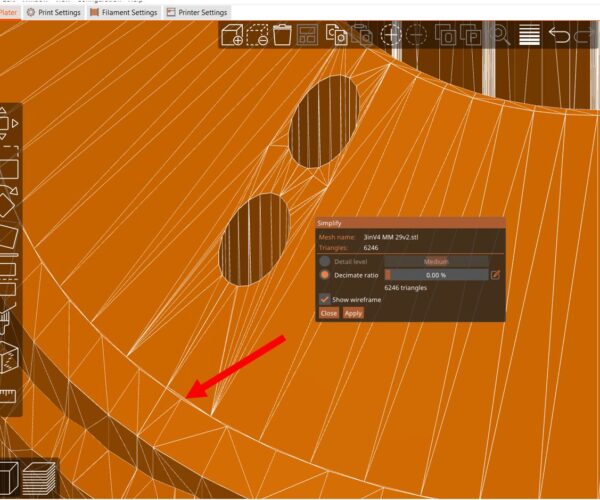

Anyway, there is a problematic spot in your model, where the shape is parallel to the build plate (red arrow) . You can see it by selecting "Simplify model" in the slicer and adjust the settings as in the picture below.

RE:

OK in the modelling program that "error" does not appear to exist. how do I fix it? is there a way to turn off error correction? its possible prusa is "adding" that in an attempt to fix a problem it finds with the model (when you view a model in prusa slicer the model is "NOT" the model you dropped in if you see errors detected IE prusa slicer has already "altered" the model and that is the result your seeing) if I can turn this off it might slice properly. I can sort of confirm this in that if I export the STL from prusa and then bring that model into simplify 3d its now "broken" and no longer slices cleanly but the original downloaded model DOES slice cleanly.

IE that extra line should not be their. fixing in netfabb might not work since prusa slicer already created that line so it will be their when it gets to netfabb.

yes I do know what vase mode is. the distance from the ribs to the outerwall is critical. it must be exactly 2x the nozzle extrusion width. in this case 0.8mm which is 2x 0.4mm the nozzle width. this is to permit fusion while still permitting "correct tool path creation" that is vase mode compliant.If you are less than this (there is a fudge factor) by too much it will percieve the outerwall as being "pierced" and this will "break" vase mode (create an island)yes its a pain but the result is insanely strong and lightweight aero components. this is a motor mount for a rocket.

I am using structural engineering to get the strength I need without the mass. if the ribs are more than 0.8mm from the outersurface they will not "fuse" with the outer perimeter and this is critical for "integrated structure integrity" Think airplane wing with wires and ribs inside to "hold it all together" as one whole "unit" its incredible efficient and effective but can be a real "PITA" to implement.

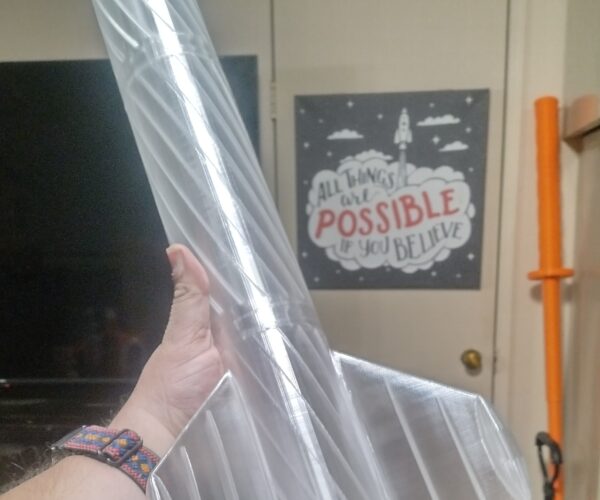

Here are some pictures of what you can do with this technique.

RE: Problem with slicing complex vase mode models

Is this more in line with your expectations?

your issue may be with 'Slice Gap Closing Radius'

Fixing With Netfabb doesn't seem to break the model

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Problem with slicing complex vase mode models

that viewing angle does not show the issue. the issue is on the side of the model where the pass through slice is. one gap half way up above first thread second cap at the transition from the threads to the "cone" on top.

Netfabb did not fix the issue.

RE: Problem with slicing complex vase mode models

and yes min gap must be zero or it makes spaghetti 🙂

RE: Problem with slicing complex vase mode models

OK in the modelling program that "error" does not appear to exist.

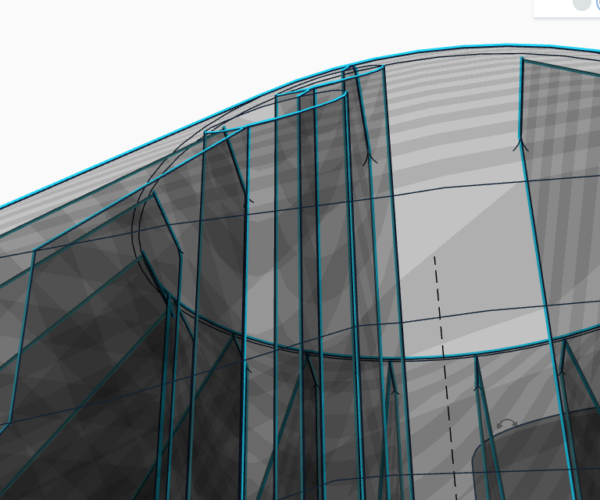

If you look closely to the STL you provided in a STL-viewer, you can see that the problematic spot exists already before loading it into Prusa Slicer.

My guess would be that there is a tiny mis-alignment or gap in your modeling program, that causes the exported STL to have that gap. It is not Prusa Slicers fault.

RE: Problem with slicing complex vase mode models

Yeah its clearly visible in that image, and with slice close gap set to zero thats going to mean they appear on the slice too.

RE: Problem with slicing complex vase mode models

I am a bit of a novice when it comes to modeling. so bear with me.

in the grayscale stl viewer image posted. what gap? I do not see a gap in the image displayed ???

I see the two different shapes on each other (looks like the polygon segments of the cone are 50% out of phase with the segments of the base but that does not create any sort of gap. the distance between those two objects is in fact 0.

Are you talking about another gap I am not seeing?

Note I am not talking about the VERTICAL GAP that bisects those holes. that's intentional. vase mode can't work without that (its 0.01mm thick) I am talking about the "missing chunk of the model" horizontally in the prusa slice but not in the S3D slice. (and a second missing chunk 50% down the side of the base component)

I don't see a gap there in your stl viewer image. what am I missing?

RE: Problem with slicing complex vase mode models

SO there must be some micro gaps I can not see in the model or in your stl viewer image either. I tried setting the min gap to a 3 decimal place number. that sort of worked. I set it to 0.008 and the missing layers came back BUT it also erased my intentional gaps even though they are 0.01mm which is larger than 0.008. I had to set it to 0.004 to get my intentional gaps back but now the missing layers issue ALSO came back. Prusa is ABSOLUTELY adding these. but it might be a micro gap and its "rounding" for some reason? clearly some rounding is occurring or my cuts would remain when I set the gap to 0.008 when my gaps are 0.01

What I might try doing is setting my gaps to 0.02 instead of 0.01. that should still "fuse" correctly I think and might separate them enough that I can set the min gap to 0.08 to eliminate whatever the heck prusa slicer is seeing to create the layer gaps. I SUSPECT it is artifacts from tinkercad and that prusa slicer is doing some "rounding" of values (honestly speaking 0.008 is pretty damned small so I can understand some rounding) I just don't understand why its ERASING part of my model to rectify those gaps. ie the problem is not whatever gaps its seeing in the model its "HOW ITS FIXING THEM" that is the problem. again slices perfectly in S3D.

RE:

I don't normally download models not zipped up and saved here but I did this one as the problem is interesting. However when I sliced your model (even with the PS reported errors) I am not getting the pictured gaps. I am using PS2.6a4.

So what version are you using ? Also this absolutely the reason we ask for a zipped up project file (3mf) saved from Prusa Slicer as that way we get a copy of all the settings you are using.

I did take the stl in to blender and removed the (very minor errors) that were in it and so I have a version that PS doesn't indicate any problems with. The only 'problem' is that the both look to slice the same. The following is your original model sliced in 2.6 and with a normal profile set to vase and 0.4 external perimeter with closing radius of 0 as you describe. It looks normal.

Those discontinuities mentioned though will cause gaps in the surface as the filament goes from point a to be and 'cuts the corner'. Better to bring the verts into alignment to make the print stronger.

RE: Problem with slicing complex vase mode models

ok its not microgaps at all. there are none in the model. I use a third shape to "cut" the other 2 shapes to make them conformal PERFECTLY to each other.

its prusa slicer. when I remove the "cuts" from the model it slices the "shell" without those gaps. When I add the cuts to the model the "missing layers" come back. those cuts are 0.08mm away from the shell (verified) they are no where near close enough to the shell to be interacting with it. prusa is "making" the interaction on its own. this is no longer about fixing the model but "working around" a bug in prusa slicer (well slic3r its likely not prusa's fault at all) and I just have to keep altering the geometry until slic3r's engine is "happy" I adjusted the sliced by 0.04mm and one gap went away. I adjusted it again by 0.05mm and the other gap (at the top) MOVED UP 0.4mm 2 layers where no issue existed before (the external shell is unchanged) so its definitely the engine "glitching" on something I am doing. so I just have to keep tweaking till the engine is happy and hope I don't have to tweak enough to lose fusion.

and the last 0.05mm shrink made it WORSE (the cuts are moving AWAY from the skin this action should ONLY make it better if it was my model)

YOU tell me where its messed up. the mesh is coming out nearly perfect now here is a transparent view. any micro gaps would be very obvious

Here is model 3 https://drive.google.com/file/d/1WSdJDGNXlgfLbXYT4NyIJAZOFEswBMWY/view?usp=sharing

Here is model 4 that got worse https://drive.google.com/file/d/1HDHoyyF2r4JfO_jzh_FNHtIu93h61-BY/view?usp=sharing

And here is the transparent view. the skin is perfect no errors and you can clearly see the gap between the rib and skin with no "micro fractions" connecting them.

RE: Problem with slicing complex vase mode models

Interesting. I am using latest release 2.5 I will go get 2.6 right now !!

Yes I aligned the shells NO CHANGE it has something to do with prusa slicer engine "creating" an interaction between the 0.01mm cuts and the "shell" even though they do not touch. I will 3mf a zip for you here I did not know I could do that (it would not accept the STL file directly which is why I did the google drive linking)

I made a common shell and use that to "cut" both components so now they "mate" perfectly without issue or gap or misalignment at all. and the problem persists.

I think its prusa slicer "interacting" the cuts with the shell because when I export without the cuts (just the main cut) it does NOT erase those layer sections. when I add them back in. the error reappears even though the two parts do not (or should not) interact in that way.

RE:

Please when sharing files zip them up and attach them here. Many forum users are not willing to risk downloading from external sites.

Also as posted previously I now think it’s something in your settings as when I slice your original model it slices fine, I can’t see any missing layers. As such can you please attach zipped up Prusa slicer project file so we can examine your configuration settings.

edit, we do seem to be posting at the same time lol. I’m about to retire for the night so will have to look in the morning. Unless someone else takes a look while I’m asleep.

RE: Problem with slicing complex vase mode models

I sliced in 2.6r4 and the gaps are STILL present!! so there must be some setting difference between my profile and yours??

RE: Problem with slicing complex vase mode models

if you can can you send me your profile settings? mine fails in 2.6 as well !!

RE: Problem with slicing complex vase mode models

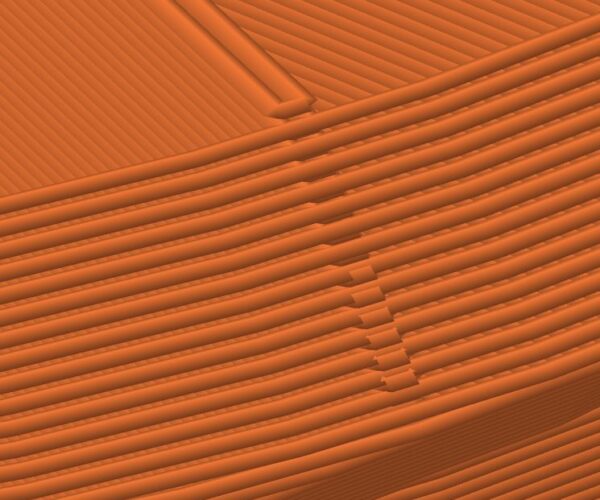

ohhhhhhh I think I found the settings !!! not only is it correctly slicing now but it also visually exposes potential problem areas in my model that I can SEE in the slice (without breaking it!) very interesting. It seems THESE needed to be set. (I though from the darned start this might have something to do with its adaptive extrusion routine !!!! I think these 3 settings would "override" that adaptive stuff!!!

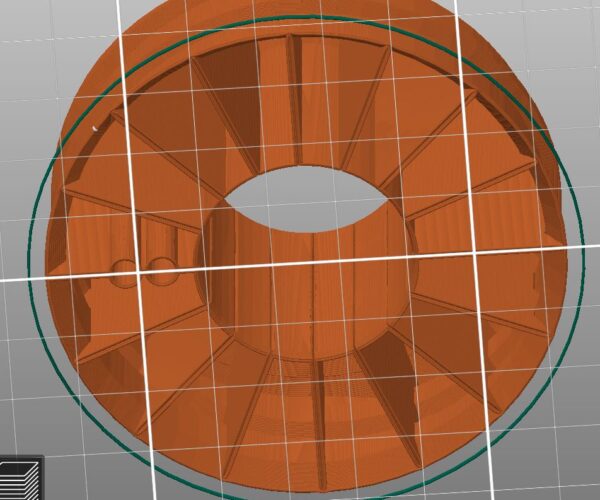

And NOW I see THIS in the slice which might actually be whats causing the issue !! except its no where near where the gaps are ???? in fact this area sliced fine. so strange but ECSTATIC I can make it work now. you clued me in with your statement of "sliced in 2.6 and with a normal profile set to vase and 0.4 external perimeter with closing radius of 0" I asked myself. I never actually SET it to 0.4mm is there other places where I can define 0.4mm and I found those settings under advanced and just set them all to 0.4mm figuring that would override adaptive extrusion which I suspect is the source of the issue.!!

This is the error I found (even though its 45' away from the problem area) it seems to indicate the cut rib is "pushing" out the wall ??? but I don't see that in the model....

but in tinkercad you can clearly see that rib is no where near the outerskin...... No idea whats going on with that

At this point I don't care. its WORKING and that is all I care about for now 🙂 hehehe

I REALLY appreciate you digging into this and helping! if you have any other insights that might help I would greatly appreciate it!! might save me some headaches in the future!!!

Been fighting with this annoyance for a few days now non stop. it was driving me nuts!