Printing rectangular Grid - each rectangle is printed seperately

Hello

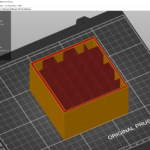

I have made a design to store individual 18650 Li-Ion cells. Now when I print, each of the rectangles is printed one after the other (per layer of course). The print is super slow, and I would expect it to be factors faster, if it would be printed line by line.

Funny enough, I found someone with the exact same problem (with Cura), and he illustrates it very well:

https://3dprinting.stackexchange.com/questions/7891/printing-rectangular-grid

Is there a way to get PrusaSlicer to print this more efficient?

RE: Printing rectangular Grid - each rectangle is printed seperately

Please save your project (save as from the file menu) which will save as a .3mf file. Zip that file up and attach it. Must be zipped for the forum to accept the file.

That way we can see the model as well as all the settings you are using. We can then easily iterate through settings to see if theres some way to make it do that. Sometime though it cant as the printed lines of the grid would have to cross over each other and so the only way is the path planning its using. Other times though tweaking something can make the difference.

RE: Printing rectangular Grid - each rectangle is printed seperately

Well - without seeing the model, I can tell you definitively unless you've done some extra work with settings, those chambers will all have a perimeter or two or three. Unless you specifically designed the part with 0.45 mm walls in that region, you will get printed squares. And making the walls 0.45 mm (0.4 mm nozzle assumed) will end in a very fragile part.

Better - if you are looking for fast and cheap - is to make that area grid infill.

RE: Printing rectangular Grid - each rectangle is printed seperately

Thanks Neophyl and tim-m30 for your answers. I have attached the project:

@tim-m30

The Chambers have 1mm wall thickness - 0.45mm is indeed too little. What about 0.9mm? Would that be printed in two "runs"?

What do you mean by "make that area grid infill"?

RE: Printing rectangular Grid - each rectangle is printed seperately

The part didn't make it. You need to create a zip of the .3mf project, then post the zip like you'd post an image to the forum.

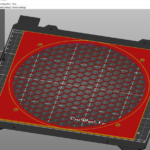

You can do things in slicer to create modified zones, and set parameters like top layer to zero, so the area you want a grid is printed as infill rather than the model. It's sort of a hack to make things that are difficult or time-consuming to model or you just need speed. And getting the infill percentage right to hold a specific battery is problematic hit or miss. Can't really recommend it now that I think about it. Great for things like fan grills where absolute opening size is a don't care; less great for bins.

Here's examples of the look: you simply drop in a modifier, set the infill type and percentage, no top layers, no perimeters.

There are finicky things that happen when you try to control wall thickness to well. You may have to play with either wall thickness in the model, perimeter extrusion values or even XY comp in the slicer settings. But dropping the wall thickness to a two perimeter value should help to speed things up - but the slicer will still draw rectangles - but fewer of them. After all - it is building perimeters. I do not know of a way to force the slice to use straight draws like it does for grid infill.

RE: Printing rectangular Grid - each rectangle is printed seperately

New Try:

https://forum.prusa3d.com/wp-content/uploads/2020/10/18650-Organizer.zip

RE: Printing rectangular Grid - each rectangle is printed seperately

@tim-m30

Ok, got it, was expecting something like this, but didn't find out how it's done.

Thanks a lot for your explanations, all makes sense. Will try with 0.9 but need to create a smaller test model, as far as I know Prusa Slicer does not show me the path it will print. And Starting such a large print to find out is a lot of material waste..

Tried again with the file, I actually uploaded it as a Zip, but seems that I linked it wrong.. now will need to wait for moderation again.

RE: Printing rectangular Grid - each rectangle is printed seperately

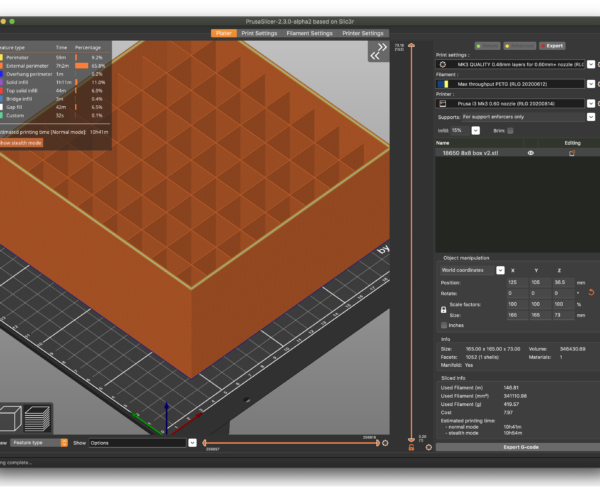

One thing that will impact that sort of print is the fact that every one of those cells is has an external perimeter. By default, external perimeters print at a fraction of the speed of the rest of the print. So in addition to the number of perimeters that must be printed, each cell is going to consist of at least one slowly printed perimeter. You can verify this for yourself by slicing the box, then viewing it in preview mode and selecting the speed option.

You can see in this example that while the non-external perimeters print at 50mm/s and infill at 200mm/s, the actual outer walls are only printing at the specified external perimeter speed of 20mm/s. You can adjust this speed, but may have quality issues above certain speeds.

For prints like this, you'll probably see a significant gain in print time by using a larger nozzle. The nozzle will still move slowly, but lay down a lot more filament with each pass. If you can save printing one or more perimeters, the time savings will be significant. A quick test swapping between 0.4 and 0.6mm nozzles shows print time estimates of 1d17h46m for the 0.4mm nozzle and 23h36m for the 0.6mm nozzle.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Printing rectangular Grid - each rectangle is printed seperately

As a practical matter - is separating the batteries so important that even one perimeter at 0.45 isn't enough material? It's still be a bomb with all those 18650's in a 200mm cube.

Here's modified file with XY Comp used to make the inner walls 1 extrusion.

Download Prusa Slicer 2.3.0A2 from github -- it has a gcode viewer to show extruder pathing. Plus a few new neat features.

RE: Printing rectangular Grid - each rectangle is printed seperately

At the moment, the cells are not separated but all oriented the same direction in multiple Boxes. I was actually looking for the OEM Style cardboard boxes, which look more or less like what I've designed here. Anyway, maybe 0.45 would be enough, will maybe look into it. I'm well aware, that a short circuit, even if theoretically impossible if all oriented the same way would lead into a big fire. That's why I want to have a good storage solution. Currently have around ~180cells to store. I'm Building Li-Ion packs for many years now, never did anything wrong, but still very paranoid - maybe better this way.

Thanks everyone, in the end it seems that I really need to find a solution to print overnight.. Even with the XY Compensation + increasing speed, I'm still way above ~16h.

RE: Printing rectangular Grid - each rectangle is printed seperately

[...] Thanks everyone, in the end it seems that I really need to find a solution to print overnight.. Even with the XY Compensation + increasing speed, I'm still way above ~16h.

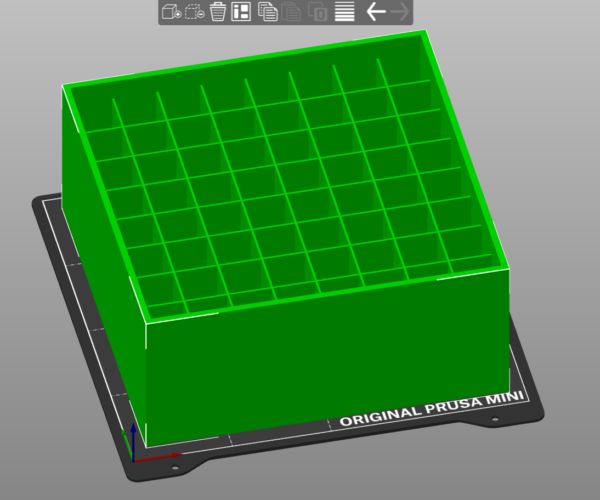

With a larger nozzle and increased layer heights, this is achievable. I sliced the unmodified box off Thingiverse using a 0.6mm nozzle with default extrusion width and 0.48mm layer height with a modified PETG profile that I've used for printing PPE in bulk. The PrusaSlicer estimate (which tends to be pretty close) is 10h41m.

Notice that the internal walls print as a single perimeter and the external walls are all solid perimeters with no sparse infill which speeds up printing. With a larger nozzle or if you're willing to push extrusion widths a bit, you can eliminate a perimeter on the external walls, dropping time down to an estimated 9h34m. You may have to experiment with filament settings when using larger nozzles, particularly the Maximum volumetric speed (MVS) setting. Different filaments will have different maximum rates at which they produce satisfactory results. Printing with a normal PLA profile, those same settings yield an increase of 1 hour (10h32m).

Obviously, the finish may not be as smooth, but I rather like the 3D printed aesthetic for storage solutions.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Printing rectangular Grid - each rectangle is printed seperately

@nioko

Currently have around ~180cells to store. I'm Building Li-Ion packs for many years now, never did anything wrong, but still very paranoid - maybe better this way.

It's the things we don't plan for that scare me... lol.

When you do get to printing these boxes, keep in mind our Printer's Nemesis: Warp! Large solid base flat boxes like to lift in the corners, so plan on increasing bed temp at least 10c after 10 layers or so are down (I might be tempted go go 15c with a full sheet box). You may even want to consider using a lot less cooling than normal.

Also - is there reason to use 0.20 mm layers here? 0.30 on a 0.4 mm nozzle should work without issue. I played a bit more - got the print time down to 16.5 hours using a 0.4 nozzle; 0.3mm layers, single perimeter, single wall chambers. Almost halving that with a 0.6 nozzle looks better.

RE: Printing rectangular Grid - each rectangle is printed seperately

Another possible aid to speeding up prints if you don't have a larger nozzle handy is simply increasing your extrusion width. Normally, you want to keep extrusion widths to 120% of nozzle size or less for quality, but you can go as wide as 200% with reasonable quality, at least if you're using quality nozzles that adhere to the E3D geometry. The width of the collar around the nozzle opening increases with nozzle size, but is always roughly 200%. This means you may be able to eliminate a perimeter by using wider extrusions.

Two caveats:

- The limitation on your hotend's maximum volumetric speed (MVS) doesn't change. MVS = Extrusion Width X Layer Height X Speed. As widths increase, you need to be prepared for reduced speeds.

- You can't increase layer heights beyond the limitation of the nozzle. Layer heights at max 80% of your nozzle size is commonly recommended as a maximum layer height to maintain good adhesion due to rounded extrusions with poor contact with layers below. You won't realize the full potential of a larger nozzle.

I use this technique when printing small miniatures with a 0.25mm nozzle. Interestingly, small features still seem to be picked out just fine, so there's no loss of resolution on small details. Perimeters and infill may be a bit faster to print. I'm printing at 0.15mm layer heights in any case, so loss of layer height is not a problem.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Printing rectangular Grid - each rectangle is printed seperately

@tim-m30

No reason for 0.20mm layers, will try 0.30.

Warp was only a very minor issue my first (canceled) print. I did however change the design to make it stackable. Will look into bed temp.

Don't know how to achieve "single wall chamber"?

BTW: Are you into batteries as well?

@bobstro

Very interesting, will look deeper into this as well.

Don't have a 0.60mm Nozzle (and not a huge fan of swapping nozzles to be honest). So will try with the 0.40. If I'm able to print 3-4 of these Boxes I'll be fine for a long time.

I think I'll need to design a smaller box, just for tests so many parameters to play with..

Thanks guys, I'll keep you posted, but don't know when I'll be able to print.