Poor surface due to bridging infill over support

Hi, fellow members!

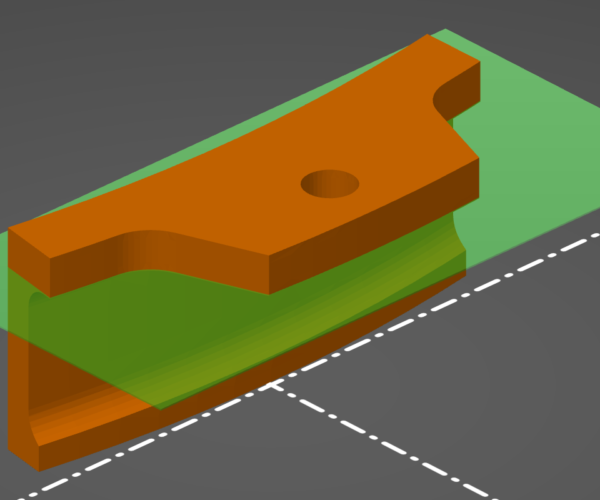

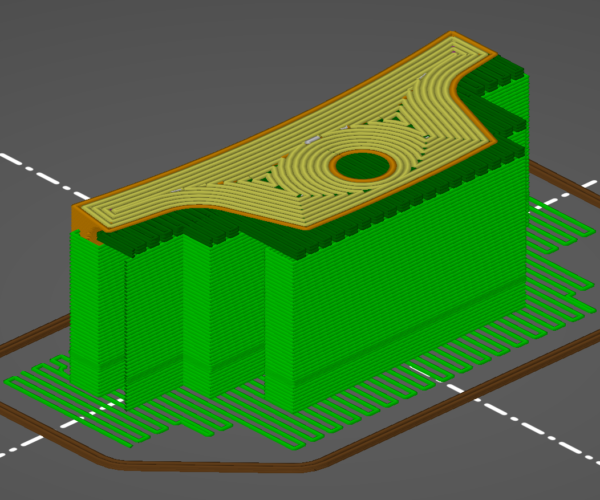

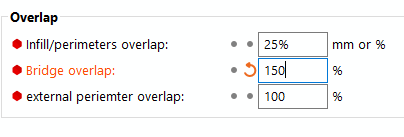

Here's piece of the detail I have issues with:

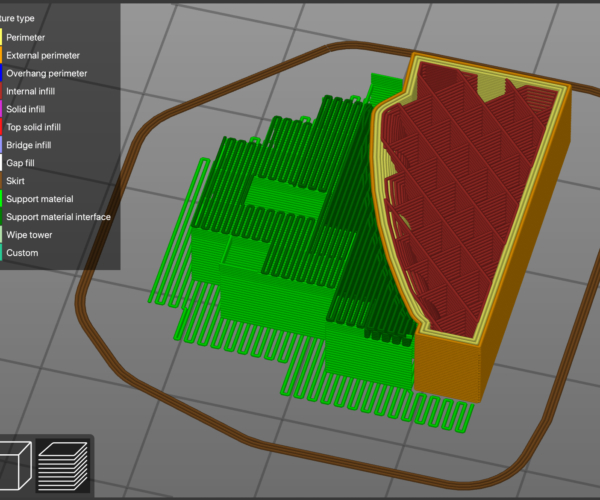

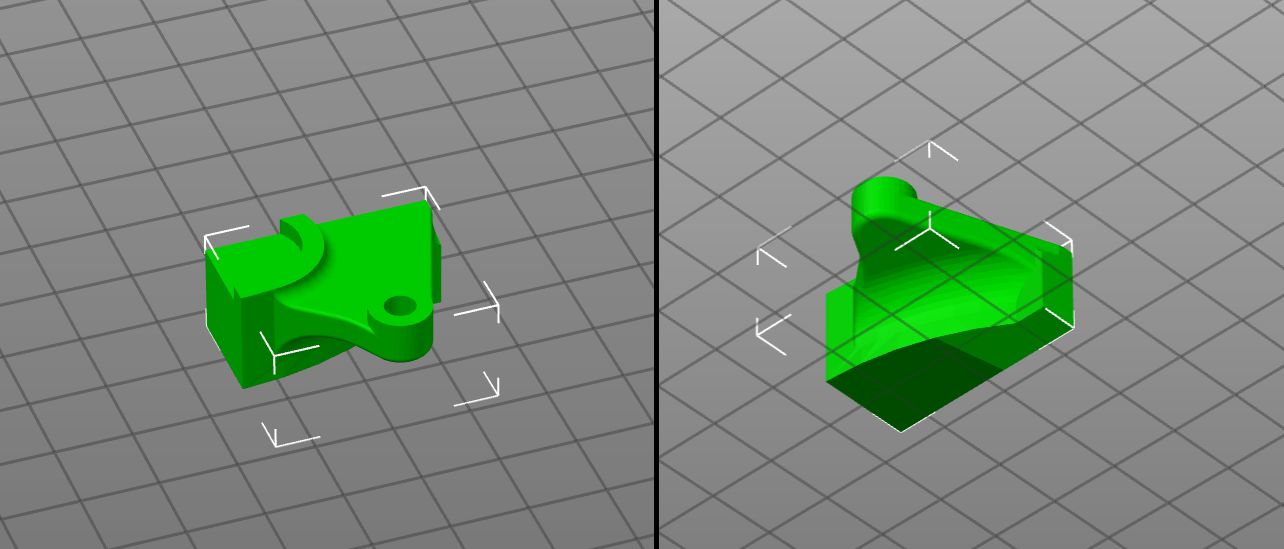

When I slice it with enabled supports I always got bridge infill layer after support and only then solid infil layer:

When I slice it with enabled supports I always got bridge infill layer after support and only then solid infil layer:

Briddge infill layer becomes a part of detail, incorporates gaps and produce poor surface. Is there any way to get rid of it and print better surface? Maybe set gaps in bridging infill to zero (haven't found such setting)? How pro would print this one (it's a part of complex structure, can't turn)?

Best regards,

your fellow additive comrade Vj_Zee_13

RE: Poor surface due to bridging infill over support

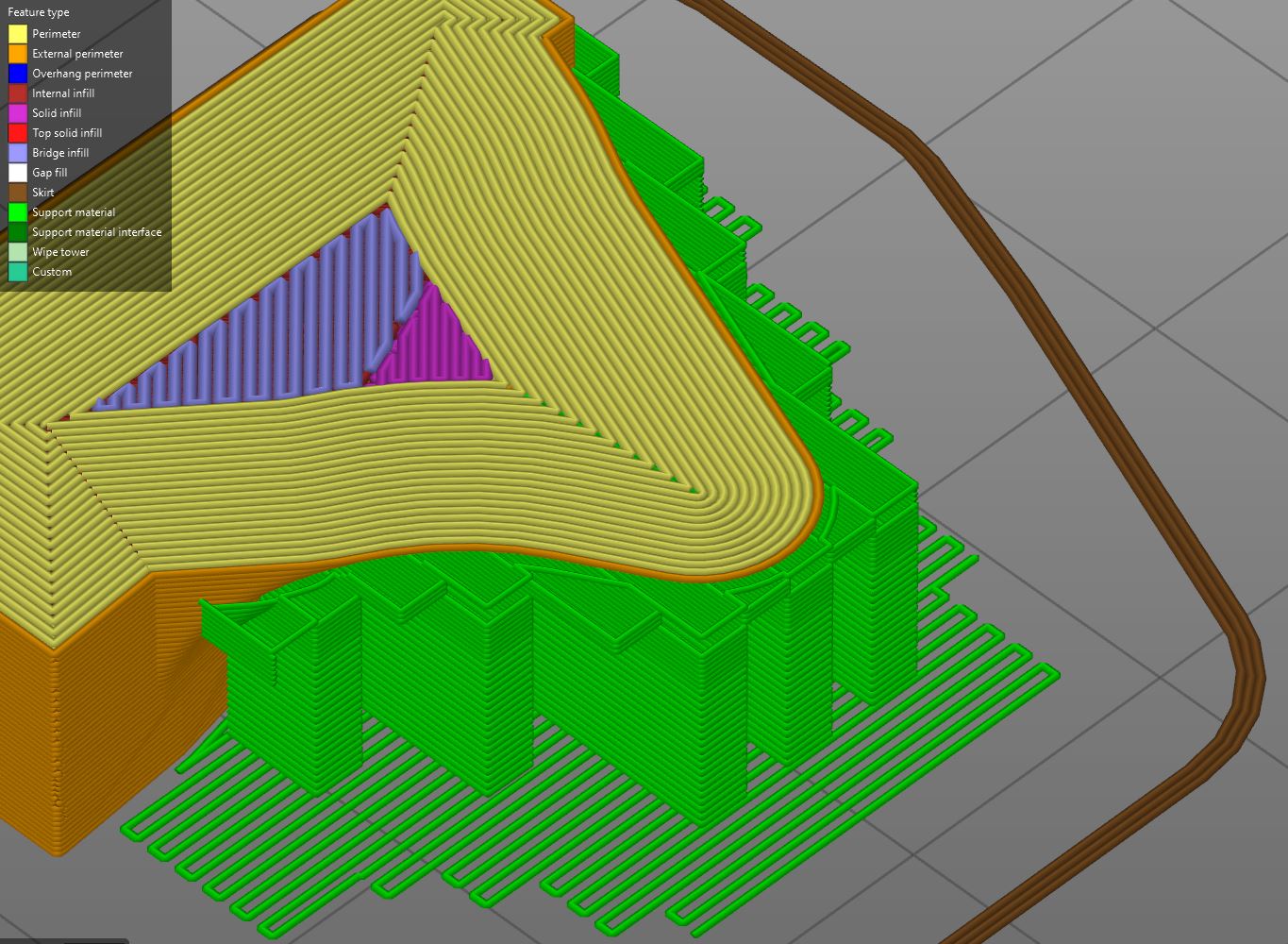

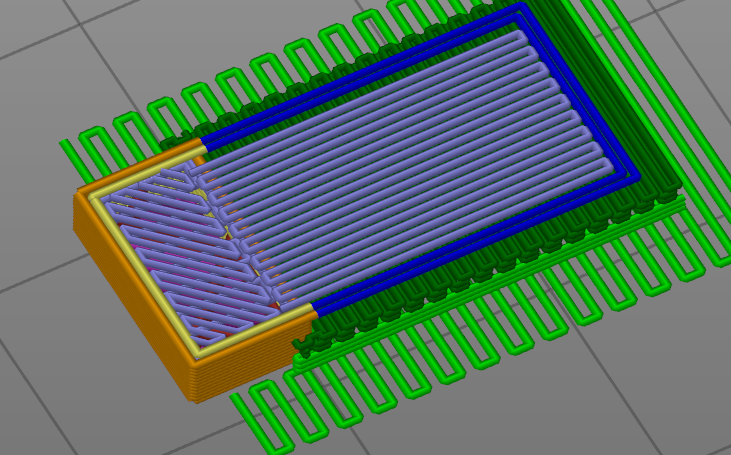

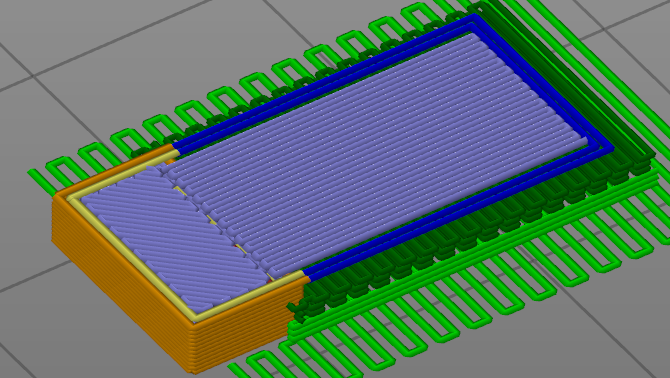

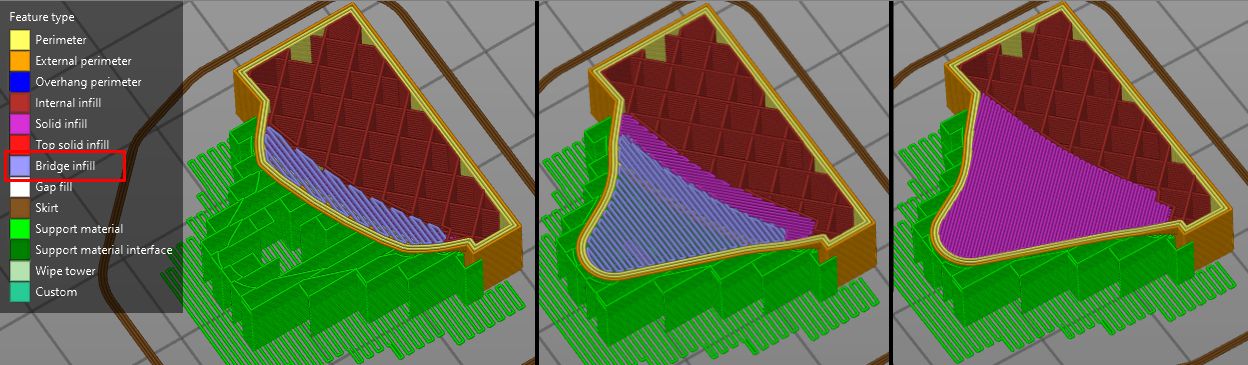

If reorienting the part is not possible, I'd try using support interface layers to provide more dense support directly under the supported layers. Try enabling Print Settings->Support material->Options for support material and raft->Interface layers (I use 3) and experiment with Interface pattern spacing (I use 0.20mm). I also increase Pattern spacing to 3 to speed things along. Here's what that looks like in the slicer:

You won't get a pretty underside this way. For FFF printed supports to be removable, there must be a gap between supports and the supported part, so the supported layers are literally printed on air. This means they won't have any squish with the underlying layers and will have those stringy extrusions with the round cross section. This might make it "good enough" however.

If this isn't adequate, you might need to consider post-processing the part, or designing it with support built in.

RE: Poor surface due to bridging infill over support

@bobstro

Thank you for your reply. I've followed your recommendations, I have stable output, but still dissatisfied with the matter concerning gaps in the first layer above support (bridge infill).

So if anyone knows how to get rid of bridging infill (or gaps in bridging infill) above supports -- you're more than welcome!

RE: Poor surface due to bridging infill over support

I am also looking for a way to control/eliminate the loathsome "bridge infill" and any help would be appreciated. I don't think it would be a problem at all if I could set it to print the bridge infill with zero spacing/gaps as vj_zee mentioned, but that doesn't appear to be an option. Is there a reason why a spaced-out bridge infill is enforced over supports with a non-zero Contact Z Distance? I really really really want just a solid infill there, even better if it would use my chosen Bottom Fill Pattern too.

RE: Poor surface due to bridging infill over support

Try using Slicer++ https://github.com/supermerill/slic3r

Sometimes, somethings are better sliced using a different slicer.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Poor surface due to bridging infill over support

Yep, having the same issue. Plicer automatically changes bridge infill's line height and line width for some reason, without a way to control it myself. Bridge flow doesn't help, because to get 0.2 mm height I have to set my flow ratio in a certain way, which gives me 0.2 mm line width for bridge! 0.2mm line width with 0.4 nozzle, you serious? I can uncheck "Detect bridge perimeters" why can't I uncheck "Detect bridge infill"? The heck. Or at least there should be an option for "Bridge line width"

RE: Poor surface due to bridging infill over support

Agree, the same problem here... The issue is that bridge infill does not stick to solid infill...

Looks ok, but it is not glued together...

RE: Poor surface due to bridging infill over support

I would also be interested in any hints toward getting nicer appearing layers immediately over supports. Mine have been similar to the photos of the black pieces above.

RE: Poor surface due to bridging infill over support

Yep, having the same issue. Plicer automatically changes bridge infill's line height and line width for some reason, without a way to control it myself. Bridge flow doesn't help, because to get 0.2 mm height I have to set my flow ratio in a certain way, which gives me 0.2 mm line width for bridge! 0.2mm line width with 0.4 nozzle, you serious? I can uncheck "Detect bridge perimeters" why can't I uncheck "Detect bridge infill"? The heck. Or at least there should be an option for "Bridge line width"

"Detect bridge infill"? The heck. Or at least there should be an option for "Bridge line width".

Couldn't agree more... This is missing...

RE: Poor surface due to bridging infill over support

Hi all!

I potentially found a work around thanks to @chocki:

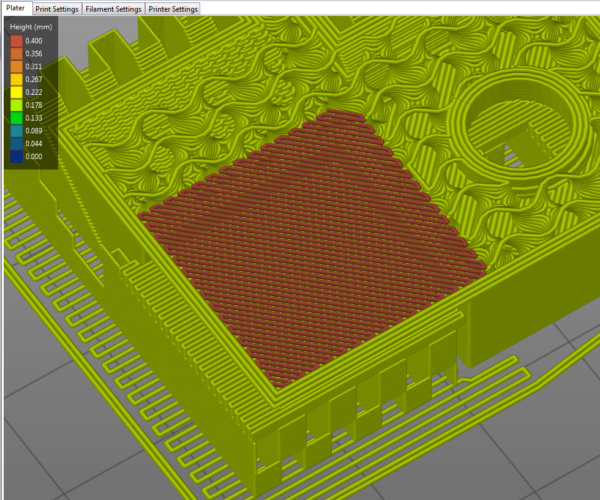

1) Create a modifier of any shape u need.

2) Reduce it to the layer hight of your print.

3) Place the modifier at the same hight as the first part layer would be printed on the support.

4) Modify the perimeter count to something, that fills the entire surface with a perimeter.

This removes any bridging perimeter and "bridge infill". One can play around with the positioning of the modifier, reduce the impact on the rest of the model.

I haven't tried it yet, but it promises to improve on our problem here.

And yes, I know its tedious, especially for prints with a lot of supports or angled supported surfaces. But until an official solution is implemented, this might be the best we have.

RE: Poor surface due to bridging infill over support

Possibly a good work around...

Change the Interface Contact Distance to zero and change the Interface Pattern spacing to .6mm.

The top layer of the support material should break off the part easily since the “strands” are so far apart.

RE: Poor surface due to bridging infill over support

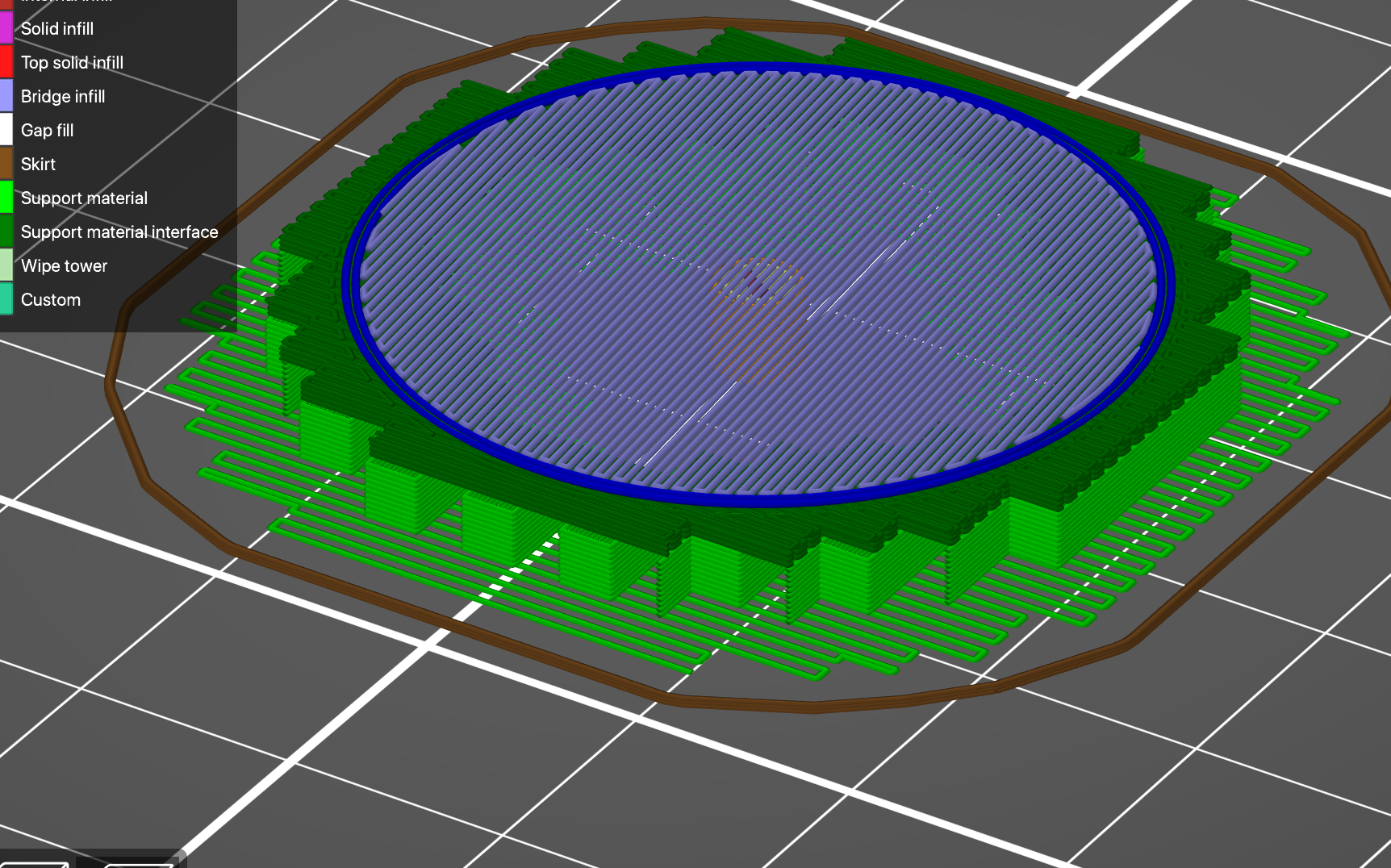

I’ve been experimenting with the extra settings in SuperSlicer (formerly Slic3r++). If you aren’t familiar with it, it’s a fork built on the current Prusa Slicer release. As such it should be very familiar to anyone who uses PS.

One of the settings gives control of the spacing of the bridge infill. I created a test part that had a 90 degree overhang, with normal support underneath (0.2 separation, 4 interface layers). With the default 100% spacing you get the normal underneath as pictured previously in this thread. However is you change it to 150% the lines are printed much closer together and the surface gets lots better. I’ll try to take a picture a bit later when I get home but it was dramatically better.

RE: Poor surface due to bridging infill over support

Before and after of what I tried one post ago, It was difficult to remove to layer under the overhangs but a Dremel made it fairly easy.

I will try doubling the Interface Layer Spacing to 1.2mm next time and share results.

RE: Poor surface due to bridging infill over support

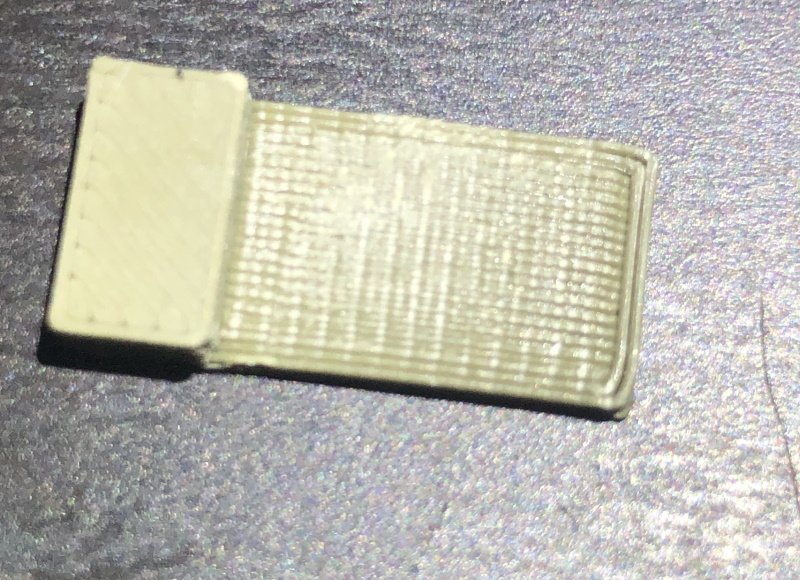

Ok heres what Ive been testing

Output print with supports removed

While its only a small piece its very encouraging and it prints in like 4 minutes so was good for quick tests.

RE: Poor surface due to bridging infill over support

Its v2.7.1, almost 2024, and problem is still there.