PETG max volumetric speed only 8mm3/s?

I have noticed, that Filament presets in PrusaSlicer for PETG are limited to 8 mm3/s of volumetric speed.

Is that concerning the actual filament limitation or is it due to the machine (MK3s, MINI) limitations?

I am trying to push the speeds with volcano and I am wondering what can I expect to work.

Thanks

Best Answer by JoanTabb:

Prusa developers create the default profiles that are included in the Prusa Slicer package, I believe they are designed to be 'conservative' profiles.

By that I mean, the profiles are offered to 'work' with a wide range of filaments, many of which Prusa have no control over.

so the profiles will err on the side of robust functionality, rather than absolute performance.

if you compare Prusament PETG, Prusa PETG and Generic PETG, settings for different nozzle sizes and printer configurations you will note that the Maximum volumetric speed varies significantly

Under Prusament PETG

A Mk3S+ with a 0.25mm nozzle has an MVS of 8mm3/S

A Mk3S+ with MMU2 and a 0.25mm nozzle has an MVS of 2mm3/S (Same Nozzle, same Heaterblock, but massively different MVS)

A Mk3S+ with a 0.4mm nozzle has an MVS of 8mm3/S whilst the MMU2 Version has 7mm3/S

A Mk3S+ with a 0.6mm nozzle has an MVS of 15mm3/S Whilst the MMU2 version has 13mm3/S

A Mk3S+ with a 0.8mm nozzle has an MVS of 20mm3/s I don't currently have a MMU2 Profile loaded for this nozzle size

If you then compare the MVS for the same printers but using Prusa PETG, you may find that the MVS are lower in some instances

If you then compare the MVS for the same printers but using Generic PETG, you may again find the MVS are again lower

Suggesting that Prusament PETG has greater flow capability than Prusa PETG, and both better than can generally be expected for Generic PETG, where the Prusa company has no control over quality.

If you then compare the prusa mini with the same nozzles and same filaments, there is more uniformity.

However, all of this information is pretty redundant because you have changed the extruder to a volcano style which has a longer melt zone and potentially greater flow capability. and to the best of my knowledge there are no default profiles for the Volcano hot end, on a mini, or mk3 printer.

I believe Prusa have placed the MVS settings in the filament section of Prusa Slicer because they think, 'at the moment' that, that is where it is most appropriate, however they adjust the MVS values relative to other settings, such as machine type and nozzle size, as they think fit. so there is no one value fits all combinations (MVS was never in 'Filament settings' drop down menu in Slic3r, which is the root from which Prusa Slicer was forked.

If you then turn your attention to Generic flex, Sainsmart TPU (Flex) and Semiflex profiles, you will see that the MVS Values plummet to new lows for the Mk3S+ Printer and the Mini.

As to why these exact values have been chosen by Prusa, you would need to ask the Prusa developers on the 'Prusa Slicer' Git Hub Page. they rarely look on this forum.

https://github.com/prusa3d/PrusaSlicer

regards Joan

RE: PETG max volumetric speed only 8mm3/s?

volcano has a bigger melt zone, so it should be able to provide more than 8mm3/s. however model geometry may prevent the printer achieving speeds that would require greater filament volumetric flow

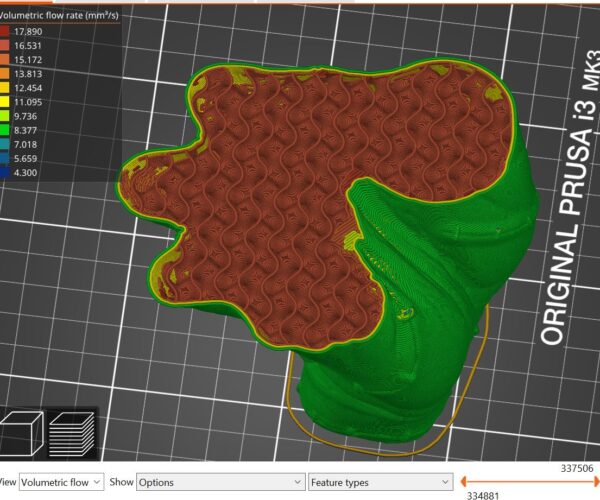

in the image above volumetric flow is set to 15mm3/s but you can see that the printer cannot achieve that rate of flow in many areas, because the settings and geometry prevent the need for high flow rates.

the outer perimeters are printed slowly, so no need for high volumetric flow

the infill and odd patches also restrict flow needed, but the inner perimeters can use higher flow rates.

with the same model, changing (Increasing) extrusion width for the infill would increase the need for volumetric flow, and

Increasing the print speed would increase the need for higher volumetric flow.

volcano is usually used with larger nozzle sizes

with the same model, changing to a larger nozzle increased the volumetric flow values significantly

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PETG max volumetric speed only 8mm3/s?

And that is why I am asking why is the filament limited to 8mm3/s? 🙂

RE: PETG max volumetric speed only 8mm3/s?

Max volumetric flow is determined by a combination of both the machines hotend/nozzle and the filament being printed. I think CNC kitchen did a video on how to determine the maximum value for a particular combination.

Once you have worked it out you can update your filament profiles with the new value.

As Joan states though, its will be other settings in the slicer that determine if you can actually take advantage of that higher capacity.

RE: PETG max volumetric speed only 8mm3/s?

Yes... I know how volumetric speed and different factors work. I am asking why is the filament (I will specify even more... Prusament PETG or Generic PETG preset that comes with the slicer) limited to 8mm3/s? Was the decision influenced only by the material or does it account for Mk3/MINI capabilities as well (even though in that case it should not be in the filament preset) or other?

RE: PETG max volumetric speed only 8mm3/s?

Prusa developers create the default profiles that are included in the Prusa Slicer package, I believe they are designed to be 'conservative' profiles.

By that I mean, the profiles are offered to 'work' with a wide range of filaments, many of which Prusa have no control over.

so the profiles will err on the side of robust functionality, rather than absolute performance.

if you compare Prusament PETG, Prusa PETG and Generic PETG, settings for different nozzle sizes and printer configurations you will note that the Maximum volumetric speed varies significantly

Under Prusament PETG

A Mk3S+ with a 0.25mm nozzle has an MVS of 8mm3/S

A Mk3S+ with MMU2 and a 0.25mm nozzle has an MVS of 2mm3/S (Same Nozzle, same Heaterblock, but massively different MVS)

A Mk3S+ with a 0.4mm nozzle has an MVS of 8mm3/S whilst the MMU2 Version has 7mm3/S

A Mk3S+ with a 0.6mm nozzle has an MVS of 15mm3/S Whilst the MMU2 version has 13mm3/S

A Mk3S+ with a 0.8mm nozzle has an MVS of 20mm3/s I don't currently have a MMU2 Profile loaded for this nozzle size

If you then compare the MVS for the same printers but using Prusa PETG, you may find that the MVS are lower in some instances

If you then compare the MVS for the same printers but using Generic PETG, you may again find the MVS are again lower

Suggesting that Prusament PETG has greater flow capability than Prusa PETG, and both better than can generally be expected for Generic PETG, where the Prusa company has no control over quality.

If you then compare the prusa mini with the same nozzles and same filaments, there is more uniformity.

However, all of this information is pretty redundant because you have changed the extruder to a volcano style which has a longer melt zone and potentially greater flow capability. and to the best of my knowledge there are no default profiles for the Volcano hot end, on a mini, or mk3 printer.

I believe Prusa have placed the MVS settings in the filament section of Prusa Slicer because they think, 'at the moment' that, that is where it is most appropriate, however they adjust the MVS values relative to other settings, such as machine type and nozzle size, as they think fit. so there is no one value fits all combinations (MVS was never in 'Filament settings' drop down menu in Slic3r, which is the root from which Prusa Slicer was forked.

If you then turn your attention to Generic flex, Sainsmart TPU (Flex) and Semiflex profiles, you will see that the MVS Values plummet to new lows for the Mk3S+ Printer and the Mini.

As to why these exact values have been chosen by Prusa, you would need to ask the Prusa developers on the 'Prusa Slicer' Git Hub Page. they rarely look on this forum.

https://github.com/prusa3d/PrusaSlicer

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PETG max volumetric speed only 8mm3/s?

Nice! So it seems like the MVS in Filament section is not really only affected by filament. Thank you, I did not know that there are different filament presets (and MVSs) for different printer configs.

Now I am just wondering why Mk3s+ with and without MMU2 has such a different MVS 🙂.

RE: PETG max volumetric speed only 8mm3/s?

I find with PETG, print quality varies with print speed and, whilst that's related to MVS, it's not the same. My (non Prusa) printer can run at quite high MVS rates but the quality is poor at high print speeds. I'm not sure if there is a better way, but all I do is increase the MVS from about 8if I'm running a test or something that doesn't need to look nice. How does the slicer deal with MVS (from the Filament Settings) as it feeds into print speed (fron the Print Settings)? I've tried to work it out and failed - I try to have the minimum number of configuration presets and resist the urge to have a range of filament specific Print Settings but I'm not sure what the best practice is?

RE:

MVS is a hard-cap limit. You can adjust it lower if you want to limit the existing speed to a specific cap (helpful if you want to have more stable temperature across the print, or have unstable sections for a tall print).

One of the other big factors that goes along with this (also in the filament settings) is in the cooling tab, specifically the minimum layer time. This will act as kind of a scaling factor once the layer times drop close to that limit, and for smaller models it can have a drastic effect on the actual max speed. If you want to see what the speed looks like without any cooling time adjustments happening, uncheck the Auto Cooling option at the top of that section. At that point, all speeds will be determined solely by feature speed and MVS.

For sanity sake, I just mess with the MVS if I care about temperature stability... or I'll drop the minimum layer time if I'm just looking for a quick print and don't care that much about detail quality. No need to save separate filament profiles, just something incorporated into normal checks.

I find with PETG, print quality varies with print speed and, whilst that's related to MVS, it's not the same. My (non Prusa) printer can run at quite high MVS rates but the quality is poor at high print speeds. I'm not sure if there is a better way, but all I do is increase the MVS from about 8if I'm running a test or something that doesn't need to look nice. How does the slicer deal with MVS (from the Filament Settings) as it feeds into print speed (fron the Print Settings)? I've tried to work it out and failed - I try to have the minimum number of configuration presets and resist the urge to have a range of filament specific Print Settings but I'm not sure what the best practice is?

RE: PETG max volumetric speed only 8mm3/s?

I tried to print PETG with higher Volumetric level, up to 15 mm3/s with 0.4 nozzle, 0.2 mm height, 0.45mm width. I tested it at speeds 30 mm/s, 60, 90, 120, 150, 180. In order to make PETG more "liquid", I increased the temperature to 240 C (usually I print in 235 C).

According calculations the 180 mm/s is out of the 15 mm3/s max level that I have put in the Filament data, so probably the printer changed it to 167. The slicer did not, the g-code file has the command G1 F10800 that is 10800 mm/min = 180 mm/s.

I printed a "typical" speed test, changing speed every 5 mm of height. The results are shown in the pictures I have included. Layer adhesion seems to be OK, line width is stable to 0.45 mm in all speed levels, the only change is the "smoothness" of the lines and their color.

The default value for external perimeters is 35 mm/s, and it is obvious that at this speed (actually 30 mm/s) the surface is perfect and shinny. At 60 mm/s (the default internal perimeter speed) the surface is a "click" less shinny but still very smooth. At 90 mm/s (that is the maximum speed according the default flow rate max level) surface is not shinny, but still lines are perfect. Rising the linear speed (and thus the volumetric speed) to 120, 150 , 180 (or 167) mm/s surface is not shinny and it is not smooth. But we have to consider that this test was a single external perimeter test with no infill.

Most of my prints are technical parts and for most of them there is not any reason for extra smoothness. Also many of them have long lines that can reach easily top speeds. So I will change the volumetric limit of PETG to 14 mm3/s (giving speed up to 155 mm/s), since it seems that is printed OK at 240 C. I will set external perimeter to 60, internal to 100 and all the rest to 150. At least for the items I do not need absolute perfect surface.

I will inform you for the results.