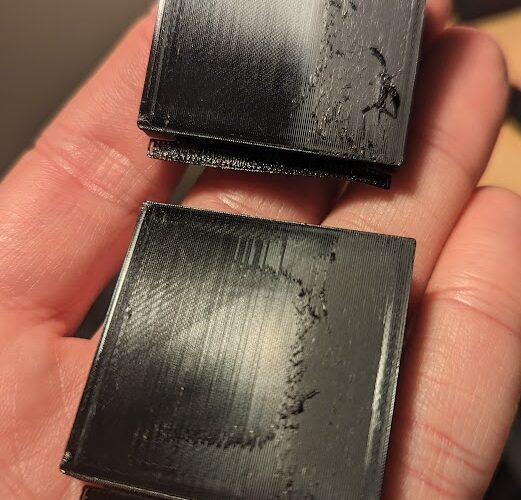

PETG Ironing Problem

I have spent the past 12 days calibrating but can't get ironing right for some reason. Looking for any advice.

Machine: Ender 3 V2 with MicroSwiss NG and Creality Sonic Pad and BL Touch

Filament: Atomic PETG 1.75

PETG is in a filament dryer while printing with moisture at 11%

I have already calibrated Z Offset, Leveling is within .03 across the board, E-Steps (as people know it) calibrated for 100mm perfectly, pressure advance calibrated, flow calibrated with flow test cube. xyz cube lookin perfect. retraction tower and bridging all good.

Things I have adjusted trying to get this right:

1. Speed 10, 11, 9, 15, 10, 11

2. Ironing Flow: 10, 15, 25, 30 (boogered badly), 20, 24.3% -none of these really made a difference other than 30 which made it worse. 24.3 was the best.

3. Distance Between: 0.1, 0.15

During testing and doing live adjustments (not on this run) was by upping the hot end to 266 and the flow to 135% which gives me that 24.3% number for flow. It made the surface glossy and smooth w/ no boogers. Or so I thought. Half way across the print it starts out as matte then boogers then goes glossy. Printing starts on the right and finishes on the left.

Manufacturer printing temp is 240-265. Bed range is 80 +/10.

I am printing at 266 bed 80. Microswiss says their hot ends need to be 5 degrees hotter to get the same effect. So that 266 is really 261. I have tried printing all the way down to 250 which the rest of the print hates.

I got nothing. Any ideas on what I need to tweak? One could say flow but I have already pushed it high enough that it boogers.

RE: PETG Ironing Problem

Also nozzle is newish and a microswiss hardened steel.

Printing < 250 gets delamination and a matte finish. to me it is like heat at the top layer but i dunno. i am as hot as i should be going imo.

RE: PETG Ironing Problem

fans are 50% and 100% for bridging. that appeared to provide the best for this setup.

still stumped.